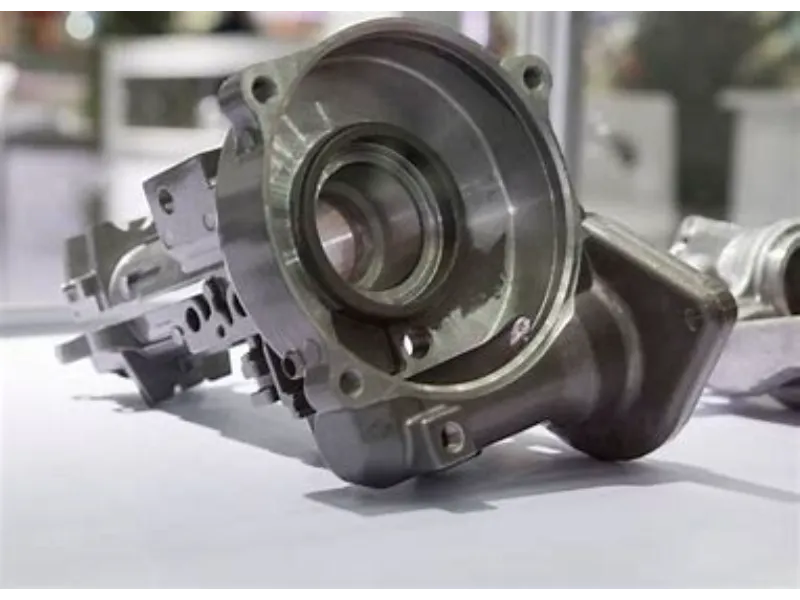

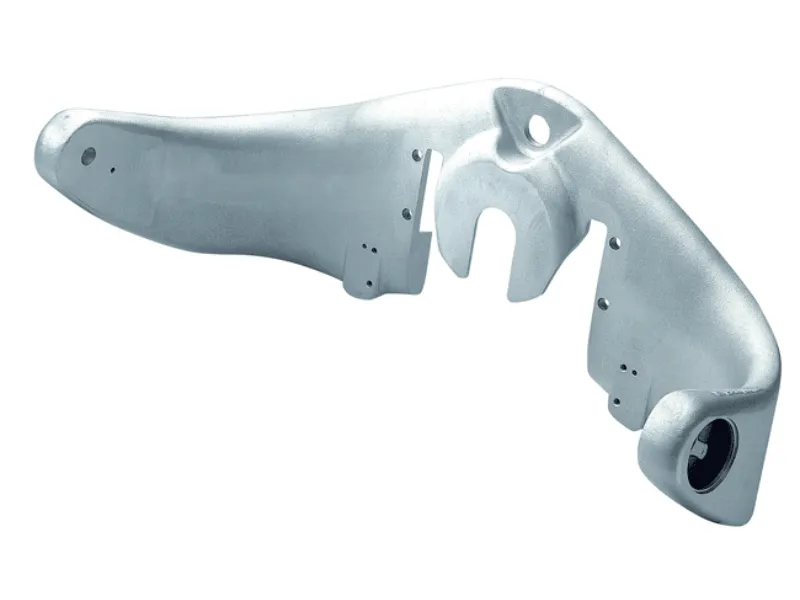

Precision Casting Solutions | High-Performance Metal Components

With a proven track record and deep industry expertise, Welle delivers high-quality metal casting solutions tailored to your needs. Our experienced team ensures precision, efficiency, and reliability at every stage of production.

✔ Expertise in Diverse Casting Processes – Ensuring high-performance components.

✔ Stringent Quality Control & Documentation – Guaranteeing superior standards.

✔ In-House Mold Production – Enabling fast and accurate sample feedback.

✔ Advanced Surface Treatment Capabilities – Delivering optimal finishes.

✔ Robust Supply Chain for Heat Treatment – Enhancing material properties.

✔ Third-Party Testing Collaboration – Verifying material composition for consistency.

✔ Customized Packaging Solutions – Meeting specific client requirements.

✔ On-Time Delivery Commitment – Keeping your projects on schedule.

✔ Proactive Issue Resolution – Addressing concerns swiftly and effectively.

Partner with Welle for precision, reliability, and innovation in metal casting.