When it comes to gears, precision, durability, and reliability are non-negotiable. At our forging components customization facility, we firmly believe that forged gears stand out as the optimal choice. Here’s why:

Unmatched Strength

Metallurgical Integrity: Forged gears undergo a process that aligns and strengthens the grain structure of the metal. This results in superior mechanical properties, making them exceptionally robust and capable of withstanding heavy loads and high torque.

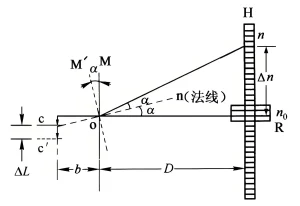

Enhanced Wear Resistance

Consistent Grain Flow: The forging process ensures a consistent grain flow throughout the gear’s structure. This inherent feature minimizes weak points, reducing the likelihood of surface cracks and improving wear resistance. Forged gears outclass other alternatives when it comes to longevity and sustained performance.

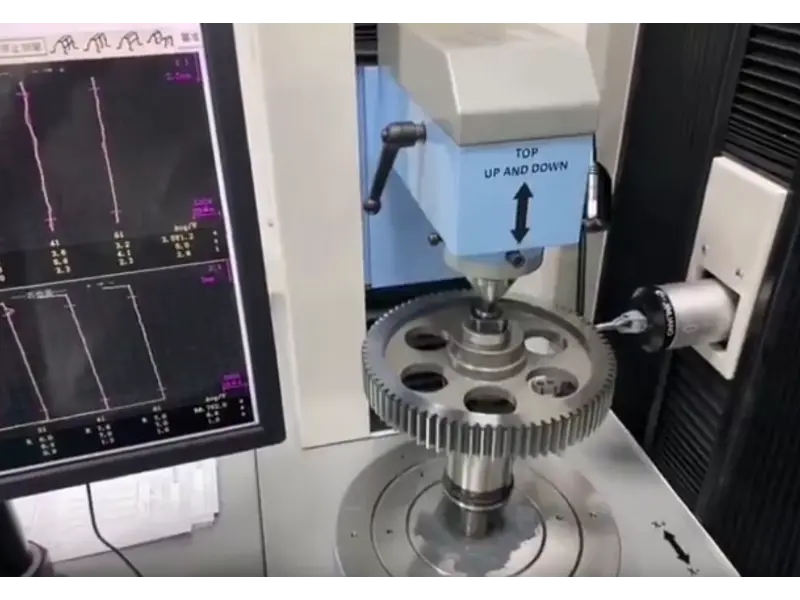

Precision in Tooth Profiles

Net Shape Forging: Forging allows for net shape or near-net shape production of gears. This means that the tooth profiles can be precisely formed during the forging process, minimizing the need for extensive machining. The result is gears with accurate tooth geometry, ensuring smooth and efficient power transmission.

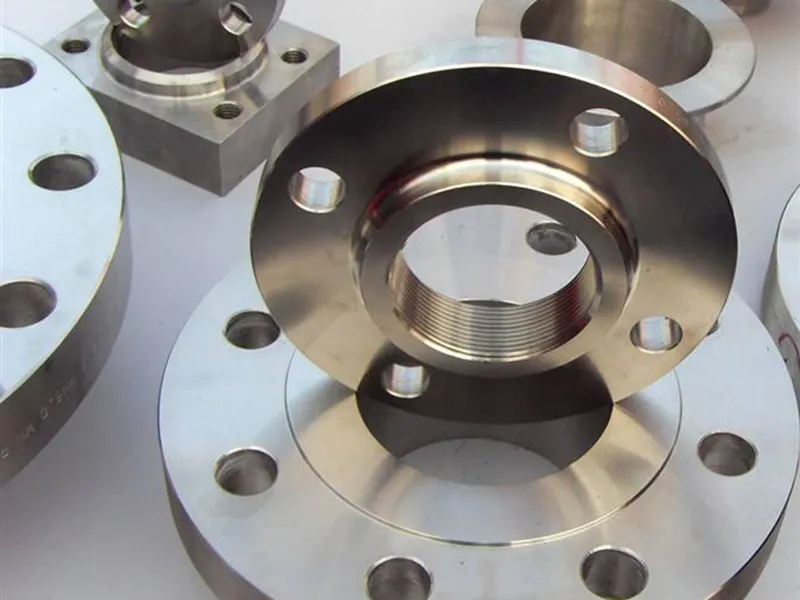

Customization for Varied Applications

Tailored Metallurgy: Forged gears offer a high level of customization in terms of metallurgy. Whether it’s alloy steel for heavy industrial applications, stainless steel for corrosion resistance, or specific alloy compositions for unique performance requirements, the forging process allows us to tailor gears to meet diverse needs.

Cost-Effective Production

Efficient Material Utilization: Forging is a highly efficient process that minimizes material waste. The precision achieved during forging reduces the need for extensive machining, contributing to cost-effectiveness. Despite being of premium quality, forged gears often present a more economical solution in the long run.

Reliable Performance Under Extreme Conditions

Consistency in Structure: The controlled forging process ensures uniformity in the structure of each gear. This structural consistency translates to reliable performance even under extreme conditions such as high temperatures, heavy loads, or rapid changes in operating conditions.

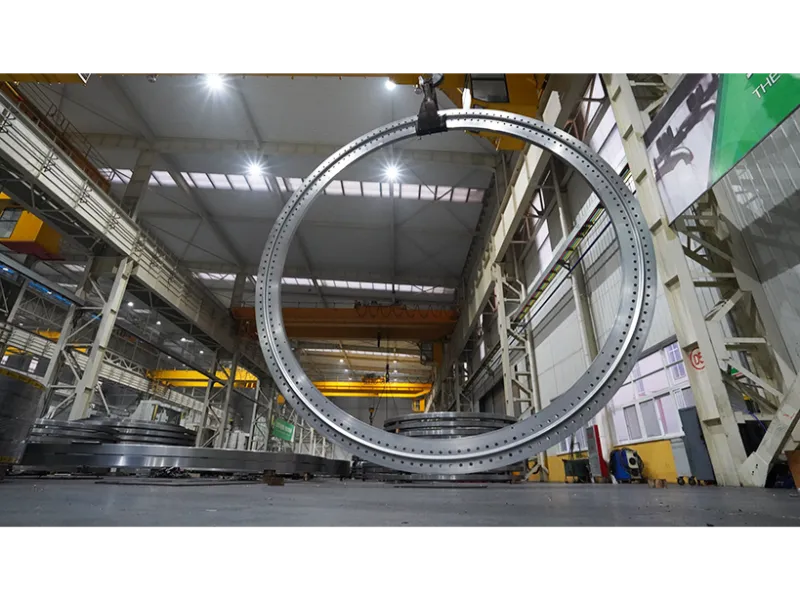

Forged Gear Components for Industrial Machinery

From complex gear systems in industrial machinery to specialized applications, our forged gear components contribute to the seamless operation of diverse equipment, ensuring reliability and longevity.

Forged Gears in Automotive Applications:

Our gear forging expertise extends to the automotive sector, providing gears that meet the stringent demands of modern vehicle systems, including transmissions, differential gears, and more.

Mining Gear Forgings:

In the challenging conditions of the mining industry, our gear forgings provide components that withstand heavy loads, ensuring the durability and reliability required for mining equipment.

Food Processing Gear Forgings:

Meeting the high standards of hygiene and performance in the food processing industry, our gear forgings offer components that contribute to the efficiency and safety of processing equipment.

Aerospace Gear Forgings:

For aerospace applications where precision and reliability are non-negotiable, our gear forgings meet the strict standards required for aircraft and spacecraft systems.

Industrial Machinery:

Forged gears are the backbone of various industrial machinery, providing the necessary strength and precision for critical operations.

Power Generation:

In power plants, forged gears play a crucial role in ensuring the smooth and efficient operation of turbines and other power transmission systems.

In conclusion, the superiority of forged gears lies in their inherent strength, wear resistance, precision, customization options, cost-effectiveness, and ability to perform reliably in demanding environments. When gearing up for excellence, choose forged gears – the epitome of reliability and durability across diverse market applications.