Product Categories

Technical Services

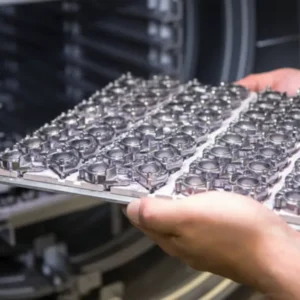

Cold Heading|Cold Extrusion

Cold forming/cold extrusion is a metal shaping process used in industries such as automotive and construction to create complex, high-precision components efficiently.

Learn MoreMetal Casting|Die Casting

Metal casting involves pouring molten metal into a mold to create a desired shape, whereas die casting employs high-pressure to inject molten metal into a mold cavity.

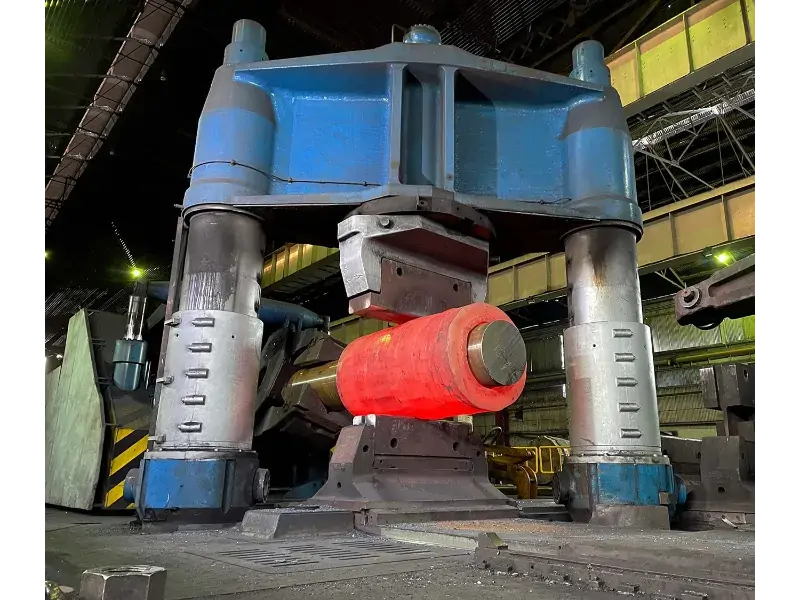

See Our Casting SolutionsSteel Forging|Aluminum Forging

Steel forging produces durable components for heavy-duty applications, while aluminum forging creates lightweight yet strong parts for aerospace, automotive, and sporting goods industries.

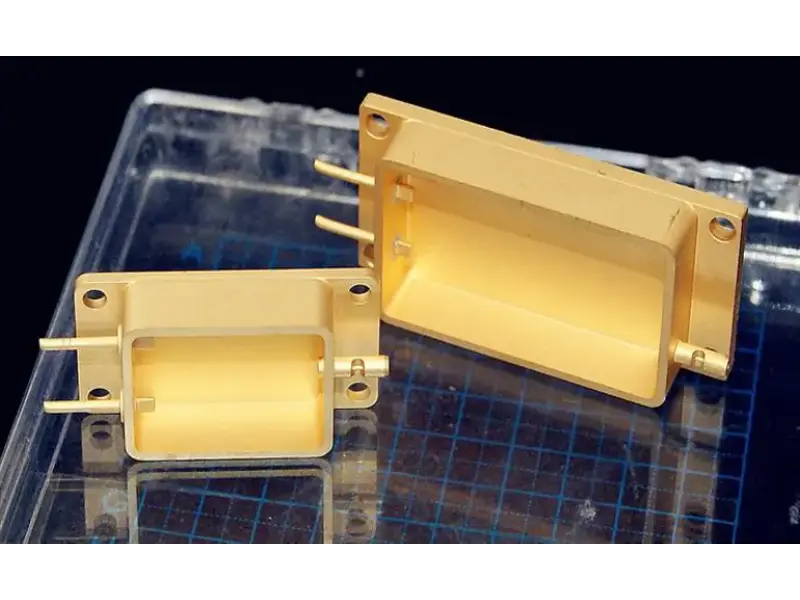

Explore Our Forging CapabilitiesPhotonics Packagings|Optical Communication Components

Photonics packaging involves the assembly and protection of optical components, while optical communication components facilitate the transmission of data through light signals in telecommunications networks.

Upload Your DrawingThreaded Rod|Screw compression|Roller

Shaft, Threaded rod, screw compression, screw extruder, and roller are mechanical components used in various industries for tasks such as fastening, material compaction, extrusion, and material shaping, mechanical transmission.

Request CNC Machining QuoteLaser Micromachining|Laser Micro Drilling

Laser micromachining enables precise material processing at a micro-scale level, while laser micro drilling creates small, precise holes in various materials for applications in electronics, medical devices, and aerospace industries.

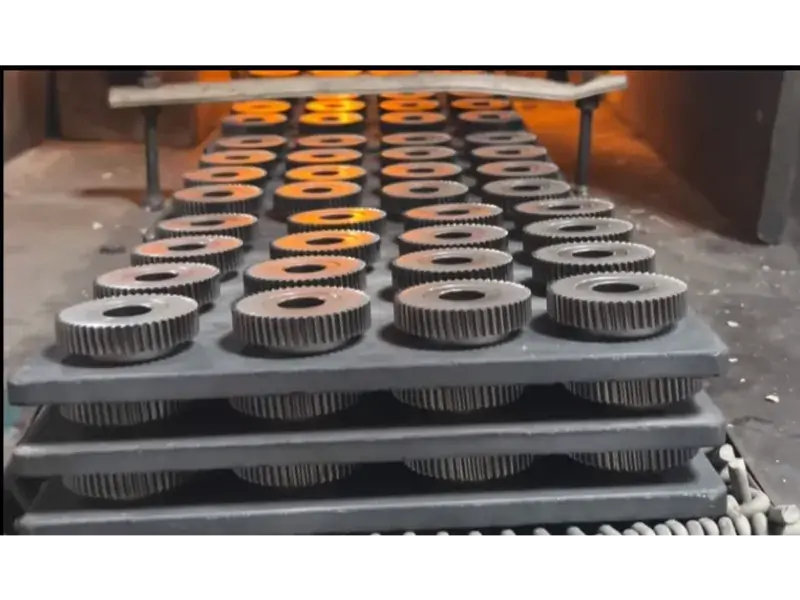

Send Drawings for EvaluationModified Gears|Custom Gears

Modified and custom gears are specifically designed and fabricated gear components to meet specific requirements, providing tailored solutions for various industrial needs.

Get a Quote for Custom GearsMetal Injection Molding|Powder Metallurgy

Metal Injection Molding(MIM) uses a mixture of metal powder and a binder to create complex shapes, while Powder Metallurgy(PM) compacts metal powders directly without the use of a binder, often for simpler shapes.

Book a Call with an EngineerPlastic Molding|Rubber Seals

Plastic molding transforms plastic materials for diverse product applications, while rubber seals provide sealing solutions in industries such as automotive, aerospace, and construction.

Discuss Your Molding ProjectValue-added Services

WELLE, As your trusted partner for custom machining solutions. From advanced engineering techniques to precise heat treatment, surface finishing, material selection, and rigorous quality testing, we offer comprehensive customization options. Experience excellence in every aspect of manufacturing with our tailored solutions. Here are your custom selections:

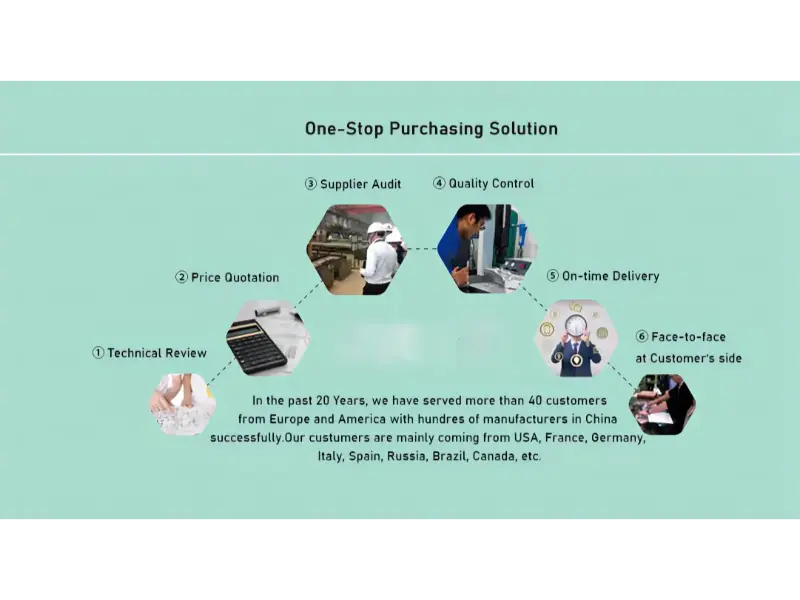

Solutions for Your Dynamic Parts OutSourcing

Quality Assurance in Offshore Manufacturing with Welleshaft

Advantages of Outsource Manufacturing with Welleshaft

- Quality Control: We ensure top-quality products by meticulously vetting factories, communicating your needs clearly, supervising production onsite, enforcing compliance standards, and promptly addressing any issues;

- Cost Reduction: Welle offers a systematic cost reduction process, leveraging expertise in material selection, process optimization, and efficient sourcing to provide high-quality products at competitive prices, ensuring client success in a secure business environment;

- Consulting and Inspection: Welle offers comprehensive sourcing cycle management, including factory selection, price negotiation, tooling monitoring, inspection services, production management, packaging, shipping logistics, and corrective action facilitation, ensuring seamless project execution and high-quality outcomes;

- Risk Reduction: Welle reduces offshore production risks through comprehensive product analysis, factory audits, meticulous tooling monitoring, transparent production processes, and client-involved factory visits;

Industries Serviced: Manufacturing & Mechanical Outsourcing

As a manufacturer specializing in custom industrial components, our expertise spans various processes including casting, forging, machining, metal injection molding, and more. Across industries such as new energy vehicles, agricultural machinery, road construction equipment, medical devices, opticals, telecommunications, and robotics, our precision-engineered parts play a vital role in enhancing performance, reliability, and innovation.

Commercial Trucks/Vehicles

Our components play a vital role in new energy vehicles, such as electric cars and hybrids. From precision-machined gearbox parts to forged chassis components, our solutions contribute to the efficiency and performance of these eco-friendly vehicles.

Agricultural Machinery

In agricultural machinery, our casted and machined parts are integral to equipment like tractors and harvesters. From forged axles for heavy-duty tillage to rubber seals for irrigation systems, our components withstand rugged farm environments.

Off-Highway Equipment

Off-Highway equipment, including asphalt pavers and compactors, relies on our forged and machined parts for durability and reliability. From precision gears for transmission systems to laser-cut blades for milling machines, our components ensure smooth road construction and maintenance.

Medical

In the medical industry, our precision-machined components are used in diagnostic equipment, surgical instruments, and implantable devices. From metal injection molded components for medical implants to laser-machined microstructures for surgical tools, our parts meet stringent quality and performance standards.

Why Choose Us As Your Contract Manufacturing Partner

From prompt quotations to competitive pricing, advanced technology to reliable transportation, and stringent quality control to efficient supply chain management, we offer a comprehensive solution to meet your manufacturing needs seamlessly.

Extensive Industry Experience

With decades of experience in the manufacturing industry, we have honed our expertise across various sectors, ensuring that we understand the unique needs and challenges of different industries.

Confidentiality Assurance

We prioritize the confidentiality of our clients’ data and sensitive information. Our robust data protection policies and stringent confidentiality measures guarantee the security of your proprietary information throughout the manufacturing process.

Thorough Factory Audits

Before partnering with any factory, we conduct comprehensive audits to assess their capabilities, quality control procedures, and adherence to industry standards. This ensures that we only collaborate with reputable and reliable manufacturing facilities.

Efficient Defective Parts Handling

In the unfortunate event of defective parts during transportation, we have established protocols in place for immediate action. Our team swiftly addresses issues, arranges replacements or repairs, and keeps you informed throughout the process to minimize disruptions.

Manufacturing Workshop

Client’s Feedback

Global Offshore Manufacturing Solutions in China

Global Reach: With our extensive network and global presence, we bridge businesses across continents, facilitating seamless communication and collaboration.

Customized Solutions: We tailor our manufacturing services to meet the unique needs of each client, fostering strong and mutually beneficial partnerships that transcend geographical boundaries.

Industry Partners

Ready to Get the Quality Outsourced Manufacturering Services?

Contact Us to Get A Free Quote Today!

Manufacturing Services FAQs

Our company implements a rigorous production monitoring and management system. From raw material procurement to production processing and final product inspection, every step is strictly controlled to ensure product quality and on-time delivery.

WELLE has passed ISO9001:2015,To ensure quality, most of our manufacturers are required to pass international quality certifications such as ISO/TS16949, ISO14001, etc. and the quality of products is guaranteed to meet customer requirements.

General Machining Tolerances on metal to +/- 0.005″ (+/- 0.127 mm) following ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”(+/- 0.254 mm).

Welle offers a precise match between customer specifications and supplier capacity with a tolerance level of up to 2 microns(±0.002mm).

For the 3D drawing, we would prefer STEP, IGES, or X_T format. For the 2D drawing, we would prefer PDF format there are tolerances with the dimensions if possible.

WELLE accepts payment in two ways: 1. Bank to bank wire transfer 2. PayPal

A Closer Look at Chinese OEM Contract Manufacturing

Manufacturing Insights: Study Cases, Blogs and Videos

About Us

Established in 2018, Headquartered in Jinan, with strategic offices across China, we’re committed to delivering excellence worldwide.Since 1996, we’ve evolved from CNC turning to a comprehensive suite of manufacturing services, including Metal injection molding&Powder Metallurgy, Gear Hobbing, Hard Turning, CNC machining, Rubber&Plastic molding, Die and Mold Casting, Metal Forging and MicroMachining,Finishing and Assembly.

With over 20 years of experience, we partner with 200+ trusted manufacturers, offering expertise in 70+ processes. Our ISO 9001:2015 certified partners ensure quality. From CNC turning to precision Laser micromachining, we provide custom solutions. Since 2016, our localized supply chain spans 23 provinces in China. In 2024, we aim to match global clients with competitive pricing, offering comprehensive manufacturing solutions, catering to automotive, optical, medical, agricultural, aerospace, off-highway and construction industries.