Optical communication photonics packages:An Overview

Welle Hermetic Packages manfacturer specializes in providing advanced solutions for optical communication photonics packaging, ensuring the reliability and performance of optoelectronic components in communication systems. Here’s why our optical communication photonics packaging services are unparalleled:

Definition: Optical communication photonics packaging involves the encapsulation and protection of optoelectronic components within hermetic packages to ensure optimal performance and reliability in optical communication systems. These packages provide a controlled environment, shielding sensitive components from external factors such as moisture, dust, and temperature fluctuations.

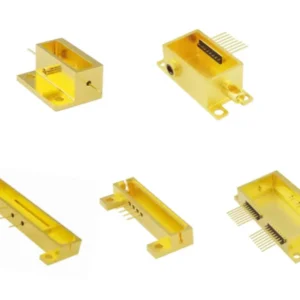

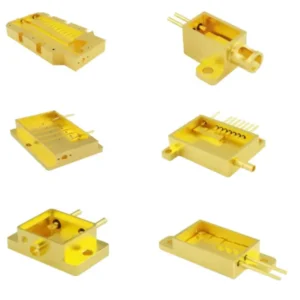

Advanced Processing Techniques: Leveraging state-of-the-art manufacturing processes, we employ advanced techniques such as precision machining, laser cutting, and microfabrication to produce optical communication photonics packages with utmost precision and consistency. Our expertise ensures seamless integration of optical components into the packages, maintaining alignment and functionality.

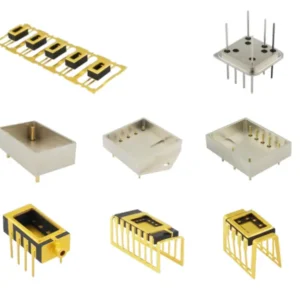

Suitable Enclosure Materials:

We offer a range of enclosure materials suitable for optical communication photonics packaging, including:

Aluminum: Lightweight and durable, aluminum is ideal for applications requiring thermal conductivity and electromagnetic shielding.

Kovar: Known for its excellent thermal expansion match with glass, Kovar is commonly used in hermetic sealing applications.

Ceramic: High-temperature stability and electrical insulation make ceramics suitable for harsh operating environments.

Titanium: With its exceptional corrosion resistance, titanium is preferred for applications requiring durability and longevity.

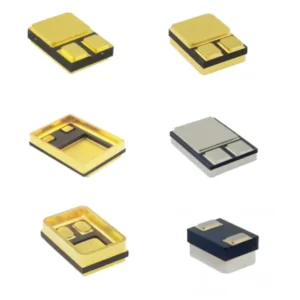

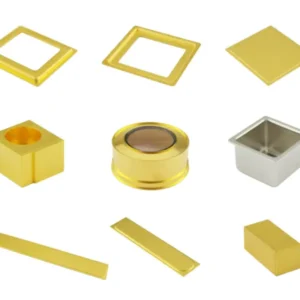

Plating Processes of Optical Photonics Packing

To enhance the performance and durability of optical communication photonics packages, we offer various plating processes such as:

Gold plating: Provides excellent corrosion resistance and electrical conductivity, ensuring reliable performance in demanding environments.

Nickel plating: Offers superior wear resistance and solderability, extending the lifespan of the packages.

Anodizing: Enhances the surface hardness and corrosion resistance of aluminum packages, improving overall durability.

Welding Techniques of Optical Photonics Packing

Our hermetic packages feature robust welding techniques such as laser welding and seam sealing to achieve reliable and leak-free seals. Hermetic wire sealing ensures a secure enclosure, maintaining the integrity of sensitive optical components.

Quality Standards of Optical Photonics Packing

Quality is paramount in every aspect of our manufacturing process. We adhere to rigorous quality control measures, conducting thorough inspections and testing to ensure the hermeticity, dimensional accuracy, and reliability of our optical communication photonics packages.

Market Applications of Optical Photonics Packing

Our optical communication photonics packaging solutions find applications across various industries, including telecommunications, data centers, fiber optic networks, and aerospace. From high-speed data transmission to long-distance optical networking, our packages provide the backbone for reliable communication systems.

Post-2024 Market Trends: Looking ahead, the market for optical communication photonics packaging is expected to witness significant growth, driven by the increasing demand for high-speed data transmission and the deployment of 5G networks. Welle Hermetic Package manfacturer is poised to lead this growth by continuously innovating and adapting to emerging technologies and market demands.

Experience innovation and reliability with Welle’s Optical Communication Photonics Packaging solutions. Trust us to deliver superior performance and durability for your optical communication systems.

Jeremy –

Generally I don’t learn article on blogs, but I would like to say that

this write-up very forced me to try and do so!

Your writing style has been amazed me. Thanks, quite great

post.

Feel free to surf to my homepage; animal fact

Lavonne –

I love your blog.. very nice colors & theme. Did you create

this website yourself or did you hire someone to do it

for you? Plz reply as I’m looking to create my own blog

and would like to know where u got this

from. thank you

Also visit my page … animal fact

Muriel –

My brother suggested I might like this blog. He was entirely right.

This post truly made my day. You can not imagine simply how much time I had

spent for this info! Thanks!

Also visit my web site; world of animal