Gear Manufacturing: Quality and Efficiency

Explore precision engineering with our Custom Helical Gears. At Welle, we specialize in helical gear solutions, from gearboxes to bevel gears. Backed by years of expertise, our gears set the industry standard for performance and durability.Elevate your machinery with our precision-crafted Custom Helical Gears.

Learn MoreElevate your machinery with our Custom Spur Gears & Ratchets at welle. Explore tailored solutions for optimal performance, from spur gear racks to precision-engineered custom gears. Trust us to drive efficiency in every rotation,propel your machinery to new heights of efficiency.

Learn MoreOptimize your systems with our Custom Worm Gears and Worm Shafts at Welle. Tailored for efficiency, our precision-crafted solutions redefine performance. From the intricacies of worm gear design to the reliability of worm wheels, our offerings are crafted for seamless integration into your applications.

As a leading bespoke gear manufacturer, we take pride in offering a comprehensive range of customization options to meet the unique needs of our clients. Our commitment to excellence extends across various facets of gear manufacturing, allowing our clients to tailor gears to their exact specifications.

By offering these customizable options, we empower our clients to tailor their gears to the precise requirements of their applications, ensuring optimal performance and longevity.

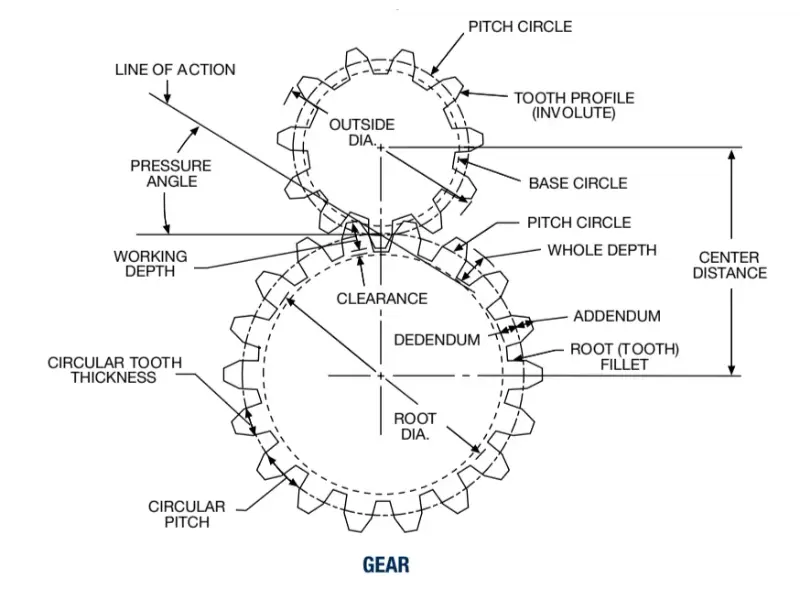

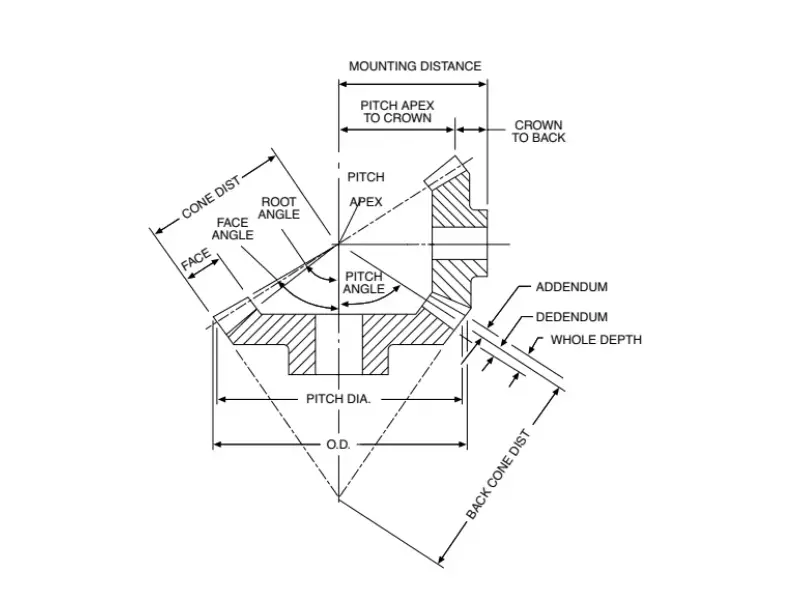

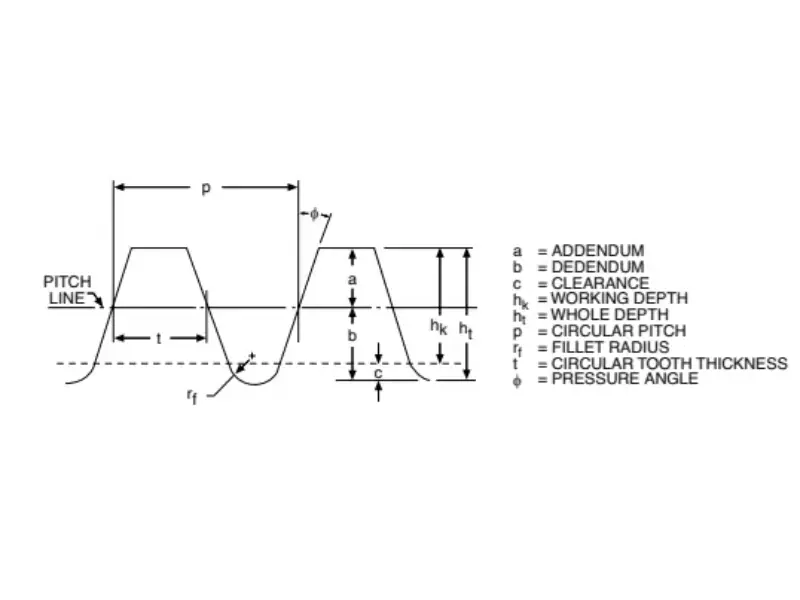

Clients can specify the pitch of their gears, determining the distance between corresponding points on adjacent teeth. This customization ensures gears are tailored to handle specific loads and torque requirements.

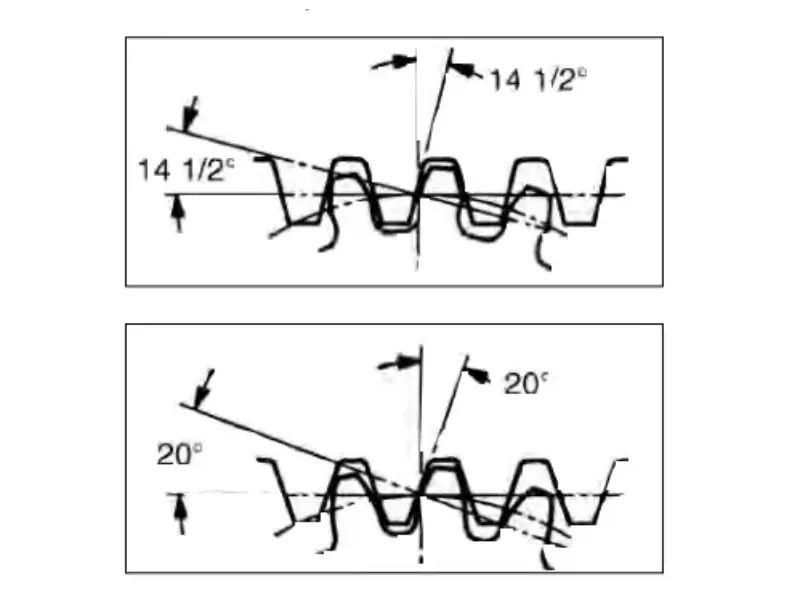

Our customization includes a variety of pressure angles, allowing clients to choose the angle between the gear tooth and its radial line. This choice influences the gear’s efficiency, noise level, and load-bearing capacity.

Clients have the flexibility to define the face width of the gears, impacting the gear’s strength and load distribution capabilities. This customization ensures alignment with the space constraints and load requirements of diverse applications.

Tailoring gears to specific applications involves determining the number of teeth. Clients can choose the optimal number of teeth based on factors like gear meshing, speed, and torque, ensuring seamless integration into their systems.

Welle excels in comprehensive manufacturing services for gears, gearbox parts, and assemblies, ensuring a commitment to excellence. Our advanced processes guarantee the highest quality and performance for each custom gear.

Gear Hobbing: Utilizing high-precision gear hobbing, we create cylindrical gears, including worm gears, helical gears, shafts, spur gears, splined shafts, and sprockets.

Gear Shaping: Gear shaping is employed for internal and external gears, crafting accurate and efficient gears such as spur gears and segments.

Gear Shaving: Precision gear shaving enhances surface finish and reduces noise, optimizing tooth geometry for superior performance in gears like spur gears, helical gears, and crown gears.

Gear Grinding: Our gear grinding process ensures tight tolerances and smooth surfaces for precision gears like spur gears, helical gears, and crown gears.

Thread Milling and Grinding: Delivering precise threads for threaded gears like single- and multi-start worms, external worms, and threads.

Machining and Grinding: Comprehensive capabilities from milling to grinding, ensuring exceptional dimensional accuracy and surface finish for various gear types.

Gear Inspection: Rigorous inspection, covering gear measuring machines, gear testers, CMM, surface finish testers, gear roll testers, and more, guarantees each gear meets specified quality standards.

Additional Services: Complementary services include deburring, assembly, laser marking, tooth rounding/pointing, heat treatment, coating applications, and custom packaging, offering a holistic solution for diverse gear requirements.

GET A FREE QUOTE

WELLE, as your trusted source for high-precision custom gears designed to elevate performance in various industries. From aerospace to renewable energy, our custom gears cater to the unique needs of each sector, ensuring optimal efficiency and reliability. Explore how our meticulously crafted gears contribute to the success of applications in aerospace, automotive, medical equipment, renewable energy, marine, mining, heavy equipment, and oil and gas exploration.

Custom gears are vital components in medical devices, including diagnostic equipment, imaging systems, and surgical tools. Our gears meet stringent quality standards, providing the precision and durability required for critical medical applications.

In the automotive and agricultural industry, our custom gears contribute to the seamless functioning of transmissions, steering systems, and engine components. Precision-crafted gears enhance overall vehicle performance, reliability, and fuel efficiency.

For industrial automation and robotics, our gears play a crucial role in ensuring precise movement and control. These customized gears are integral to robotic arms, automated machinery, and production line systems, enhancing efficiency and productivity in manufacturing processes.

Custom gears play a crucial role in the mining and heavy equipment industry, providing the necessary torque and durability for machinery used in excavation, drilling, and material handling processes. These gears withstand rugged conditions and ensure continuous operation.

Yes, we can offer a preliminary estimate based on the specifications and quantity you provide, delivering competitive custom solutions.

Certainly, we can provide comprehensive traceability information throughout the production process, ensuring a clear understanding of the gear manufacturing.

Yes, we welcome and support regular communication to ensure you are informed about project progress and can participate in decision-making.

Yes, we offer comprehensive after-sales service to ensure you receive timely and effective support in using custom,modified and standard gears.

We are flexible to accommodate various order quantities, welcome small-batch customization, and do not have a fixed minimum order requirement.

Absolutely, at Welle, we understand the critical importance of selecting the right material for your gears to ensure optimal performance and longevity in your application. We offer a diverse range of material options, including commonly used grades and alloys:

Our material selection process considers mechanical properties, thermal conductivity, and cost-effectiveness. Our team of experts is ready to assist you in choosing the optimal material and grade for your custom gears, ensuring reliability and outstanding performance in your machinery.