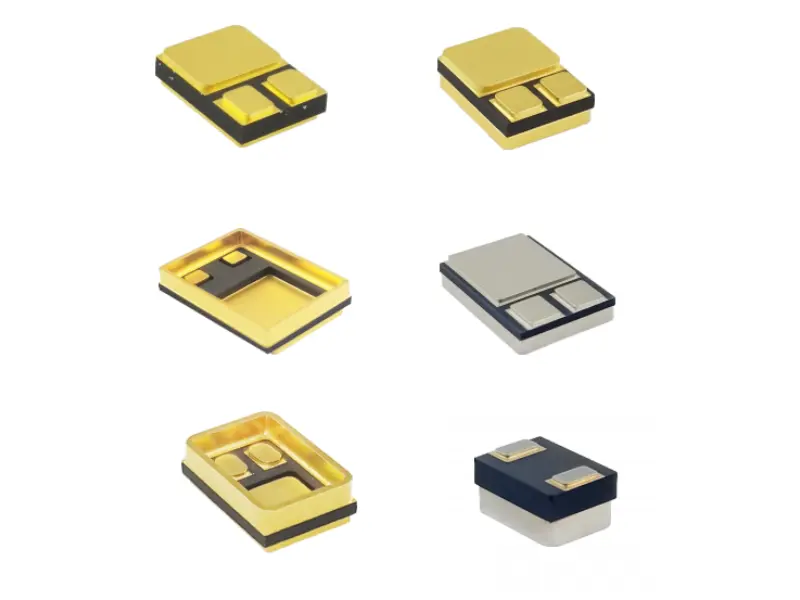

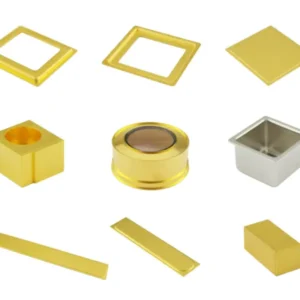

Surface mount ceramic packages:An Overview

At Welle Hermetic Packages manufacturer, we specialize in crafting superior surface mount ceramic packages tailored for electronic devices, ensuring reliability, durability, and optimal performance. Here’s why our surface mount ceramic packages are the epitome of excellence:

Understanding of Surface mount ceramic packages:

Surface mount ceramic packages for electronic devices encompass the encapsulation and protection of sensitive electronic components within hermetic ceramic enclosures. These packages offer a robust housing solution, shielding delicate electronics from environmental factors such as moisture, dust, and temperature variations.

Advanced Processing Techniques of Surface mount ceramic packages:

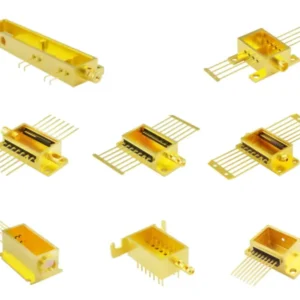

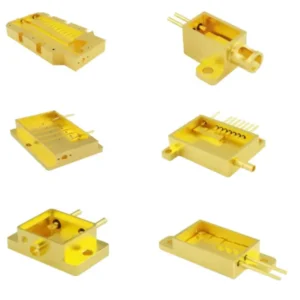

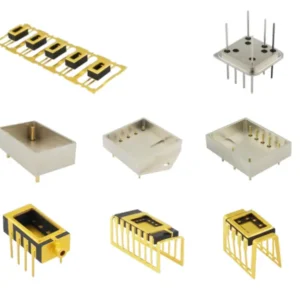

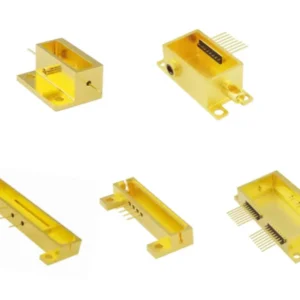

Utilizing cutting-edge manufacturing processes, we employ advanced techniques such as precision machining, laser cutting, and microfabrication to craft surface mount ceramic packages with unparalleled precision and consistency. Our expertise ensures seamless integration of electronic components, maintaining alignment and functionality.

Suitable Enclosure Materials of Surface mount ceramic packages:

We offer a diverse range of ceramic materials for surface mount packages, including high-temperature co-fired ceramic (HTCC) and low-temperature co-fired ceramic (LTCC). These materials provide excellent thermal stability, electrical insulation, and mechanical strength, making them ideal for demanding electronic applications.

Plating Processes of Surface mount ceramic packages:

To enhance the performance and longevity of surface mount ceramic packages, we offer various plating processes such as gold plating, nickel plating, and solder mask deposition. These processes provide corrosion resistance, solderability, and electrical conductivity, ensuring robust interconnectivity and reliability.

Welding Techniques of Surface mount ceramic packages:

Our surface mount ceramic packages feature robust welding techniques such as laser welding and seam sealing to achieve reliable and hermetic seals. This ensures the long-term integrity and protection of electronic components, even in harsh operating environments.

Quality Standards of Surface mount ceramic packages:

Quality is ingrained in every aspect of our manufacturing process. We adhere to rigorous quality control measures, conducting thorough inspections and testing to guarantee the hermeticity, dimensional accuracy, and reliability of our surface mount ceramic packages.

Applications of Surface mount ceramic packages:

Our surface mount ceramic packages cater to a wide range of electronic devices, including crystal units, crystal oscillators, SAW filters, duplexers, MEMS devices (accelerometers, gyroscopes, pressure sensors, magnetic sensors, infrared sensors, micro mirror arrays, silicon microphones, silicon oscillators, RF MEMS switches, etc.). These packages find applications in telecommunications, automotive electronics, aerospace, medical devices, and consumer electronics industries.

Main Features of Surface mount ceramic packages:

Exceptional Hermeticity: Our surface mount ceramic packages provide a high level of hermeticity, ensuring the long-term reliability and stability of enclosed electronic components.

Superior Thermal Management: Designed to dissipate heat efficiently, our packages offer excellent thermal conductivity, preventing overheating and ensuring optimal performance.

Miniaturization: With a focus on compact design and high integration, our packages enable the miniaturization of electronic devices without compromising functionality or reliability.

Enhanced Electrical Performance: Our packages feature precise electrical interconnects and shielding, minimizing signal loss and electromagnetic interference, thus optimizing the electrical performance of enclosed components.

Elevate your electronics with Welle’s Surface Mount Ceramic Packages. Trust us to deliver superior quality, reliability, and performance for your electronic devices.

Reviews

There are no reviews yet.