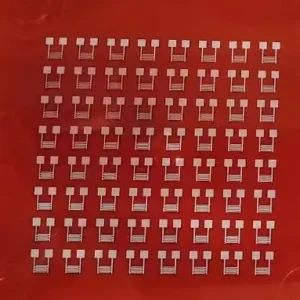

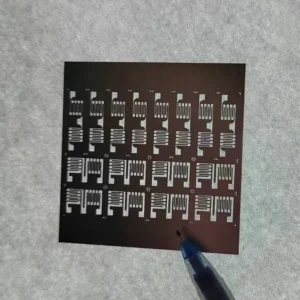

Metal Laser Micro-cutting materials,product features,applications

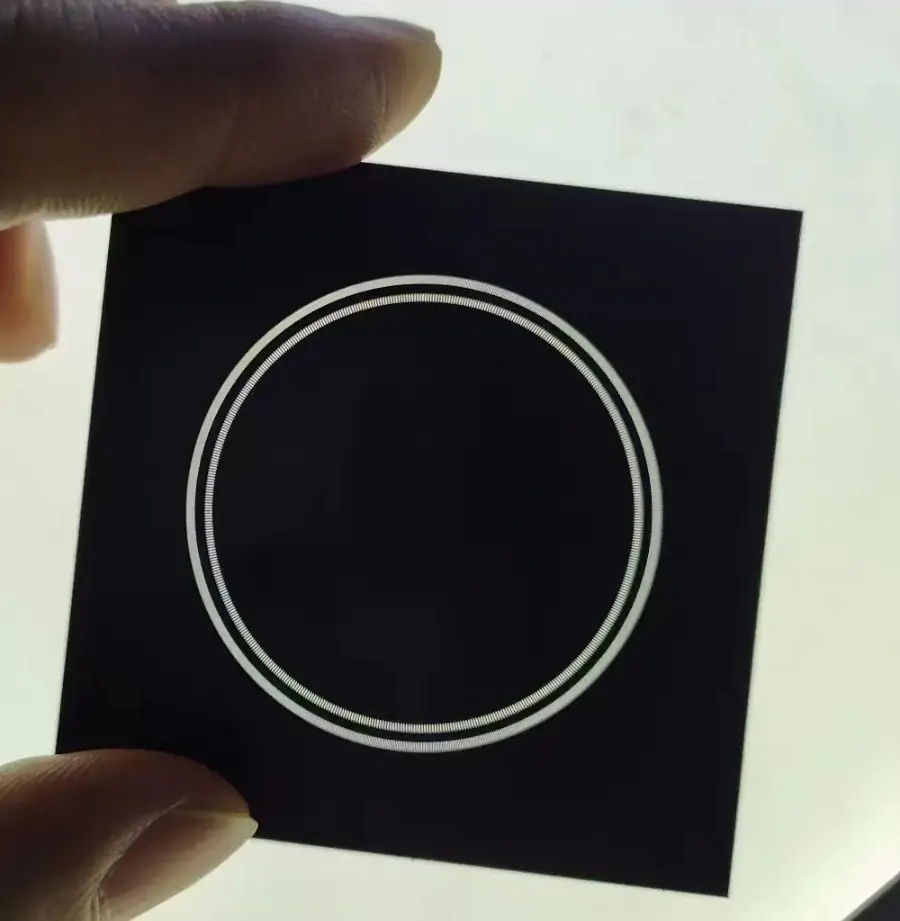

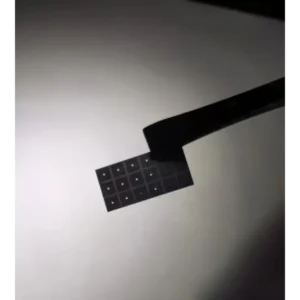

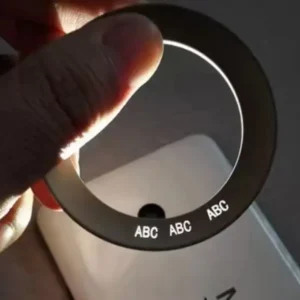

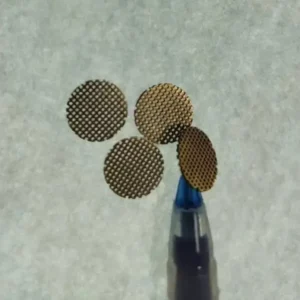

Metal laser micro-cutting and milling involve the use of advanced laser technology to precisely cut and mill metal components at microscopic levels. It is a highly precise and versatile manufacturing process suitable for creating intricate geometries and features in metal parts with exceptional accuracy.

Laser Micromachining Processes

-

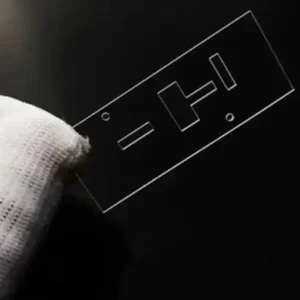

Laser Micro-Cutting: Utilizes a high-powered laser beam focused to a tiny spot size to cut through metal materials with high precision. The process is computer-controlled, allowing for intricate designs and precise cuts at micro-scale dimensions.

-

Laser Micro-Milling: Involves using a focused laser beam to remove material from the surface of a metal workpiece, creating complex shapes and features with micron-level accuracy.

Applicable Materials of laser micro-cutting

- Metal laser micro-cutting and milling are suitable for a wide range of materials, including:

- Stainless Steel

- Aluminum

- Titanium

- Copper

- Brass

- Nickel Alloys

- Alloy Steels

- Precious Metals (Gold, Silver, Platinum)

Product Features of Laser micro-cutting

- Microscopic Precision: Offers unparalleled precision at micro-scale dimensions, allowing for the creation of intricate features and geometries.

- Versatility: Capable of cutting and milling a variety of metals, enabling the fabrication of complex components with diverse material properties.

- High-Speed Processing: Laser micro-cutting and milling processes are highly efficient, enabling rapid production of micro-scale components with minimal material wastage.

- Non-Contact Machining: Minimizes the risk of material distortion or damage, ensuring high-quality finished parts with smooth surfaces and precise dimensions.

- Customization: Enables the fabrication of customized components tailored to specific design requirements, offering flexibility in product development and prototyping.

Main Applications and Market Areas of Laser micro-cutting processes

- Metal laser micro-cutting and milling find applications in various industries, including:

- Microelectronics: for manufacturing microelectromechanical systems (MEMS), sensors, and semiconductor components.

- Medical Devices: for producing surgical instruments, implants, and microfluidic devices.

- Aerospace: for fabricating miniature components for satellites, drones, and aerospace instrumentation.

- Automotive: for micro-machining engine components, fuel injectors, and automotive sensors.

- Optics and Photonics: for creating precision optical components, micro-lenses, and photonic devices.

2025 Market Trends of Laser micro-cutting and milling processes

- The market for metal laser micro-cutting and milling is expected to witness robust growth driven by advancements in laser technology and increasing demand for miniaturized components in various industries.

- Growing adoption of microfabrication techniques in emerging fields such as biotechnology, nanotechnology, and quantum computing will fuel market expansion.

- Integration of automation and robotics into micro-machining processes will enhance efficiency, productivity, and cost-effectiveness.

- Demand for lightweight, durable, and high-precision metal components in industries such as aerospace, automotive, and medical devices will drive the adoption of laser micro-cutting and milling technologies.

Related Product Keywords:

- Laser Cutting and Drilling

- Laser Marking and Engraving

- Laser Scribing

- Laser Texturing and Patterning

- Laser Structuring

- Ultrashort Pulse Laser Micromachining

- Laser Microprocessing

- Laser Micro-Drilling

- Laser Micro-Marking

- Laser Micro-Welding

- Laser Microbeam

- Laser Micromachined

- Femtosecond Laser Micromachining

- Laser Microcutting

- Laser Micro-Patterning

- Laser Micromilling

- Hole Drilling

- Nozzle Drilling

- Laser Manufacturing

- Custom Micro Cutting & Machining Service

- Micro-Parts

- Laser Etching

- Calibrated Micro Holes

Reviews

There are no reviews yet.