Surface Treatments for Industrial and Custom Metal Components What Are Comprehensive Surface Treatments for Mechanical and Metal Components? We provide a wide range of surface treatments designed to enhance the durability, appearance, and performance of metal components. These treatments include both electrochemical and mechanical processes, which can be performed in-house or through trusted external partners to ensure flexibility and high-quality results. Surface Treatment Description Benefits Typical Materials Anodizing Electrochemical process that thickens the natural oxide layer on metal surfaces Corrosion resistance, non-conductive, improved wear Aluminum, light metals Electroless Plating Chemical deposition of metal coatings such as nickel-phosphorus Corrosion protection, wear resistance, decorative finish Metals, alloys Passivation Acid treatment removing free […]

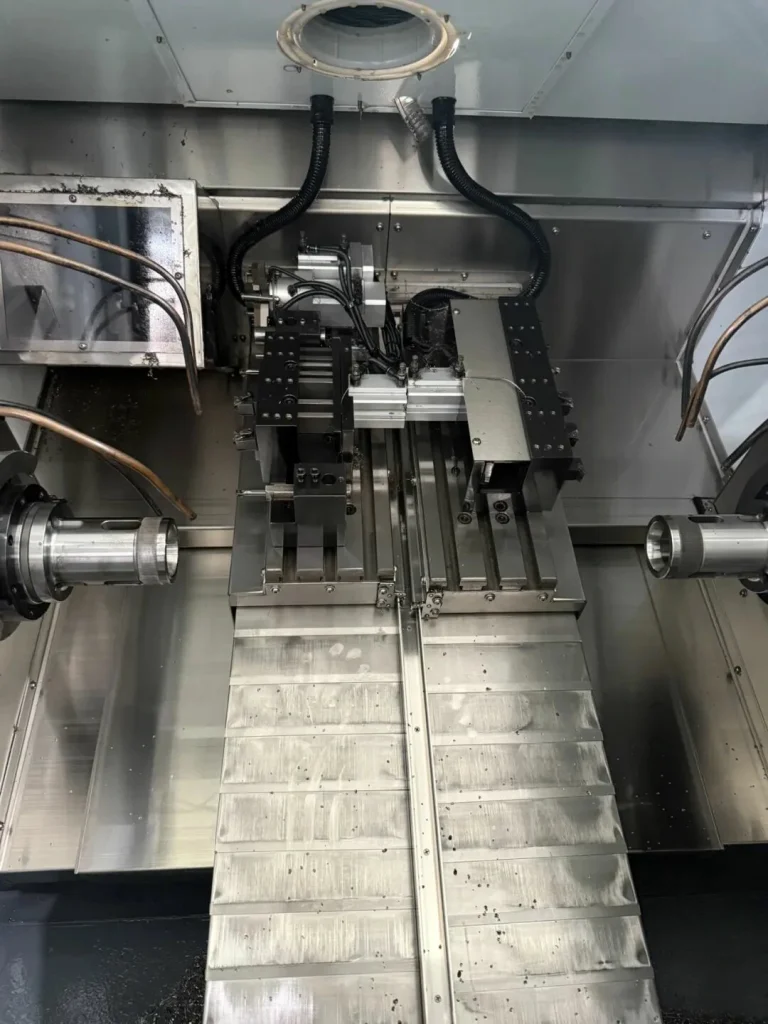

Precision Custom Multi-Axis CNC Machining Services What Is Precision Custom Multi-Axis Machining Manufacturing? Precision Custom Multi-Axis Machining Manufacturing delivers tailored solutions for complex components by integrating advanced 3, 4, and 5-axis CNC technologies into one seamless production strategy. Unlike basic machining methods, Multi-Axis CNC Machining actively enhances flexibility, improves geometric accuracy, and achieves tight tolerances required for high-performance industries such as aerospace, medical devices, and automotive systems. To begin with, 3 Axis CNC Machining provides reliable precision for simple to moderately complex components, including standard milled parts and precision CNC milling parts. It ensures consistent dimensional accuracy and excellent surface finishes, making it a cost-effective option for many structural and mechanical […]

CNC Machining and Automation for Precision Manufacturing What is Precision Manufacturing? Precision manufacturing is essential for producing components with tight tolerances and exact specifications, ensuring every part meets strict standards for size, shape, and performance. Using advanced tools like CNC machines and professional CNC Machining Services, this process reduces human error and delivers consistent results from prototypes to mass production, enhancing product quality and reliability. The demand for precision manufacturing keeps growing. New products across industries often require small, highly precise components that can only be produced through meticulous machining and specialized CNC Machining Services. This trend highlights the increasing importance of high-precision parts for modern manufacturing. In industries where […]

Aluminum Motor Housing for Motion Control: Custom Manufacturing Solutions What is a Motor Housing? A motor housing is the external enclosure of an electric motor, designed to protect key components such as the rotor, stator, bearings, windings, and commutator while maintaining precise alignment for optimal performance.An Aluminum Motor Housing for Vehicle & Motion Control further enhances efficiency by offering lightweight strength and superior heat dissipation, making it ideal for automotive and precision motion applications. A high-quality motor housing delivers several critical benefits: Precision Tolerance:Maintains exact alignment of internal components for consistent operation. Durability:Resists vibration, mechanical stress, and temperature fluctuations to prolong motor life. Sealing Performance:Prevents oil leakage and shields components from […]

Happy Chinese New Year 2026! welleshaft sincerely appreciates your continued trust and the smooth collaboration over the past year. It’s been a true pleasure working with you, and welleshaft is grateful for the opportunity to grow alongside you. As welleshaft steps into the Year of the Horse, we wish you and your team a strong, successful start and a year ahead filled with outstanding achievements. Should you have new goals or projects in the coming year, welleshaft would be delighted to support you every step of the way. Here’s to even greater results and deeper partnership in 2026. Warmest regards, welleshaft Team

Ball Screw Machining: Complete Guide to Process, End Machining & Hard Turning What is ball screw machining? Ball Screw Machining (also referred to as Ball Screw Maching) unlocks exceptional precision—a high-performance manufacturing process that uses precision-engineered ball bearings to convert rotary motion into smooth, reliable linear motion. First and foremost, this advanced ball screw machining technique is trusted across aerospace, semiconductor, and medical device manufacturing—industries where micron-level accuracy is non-negotiable. How does it work? Ball screws guide bearings along the screw axis, enabling friction-free linear movement with unmatched consistency. As a result, ball screw machining enables complex geometries with outstanding repeatability and zero compromise on quality. Moreover, our tailored ball […]

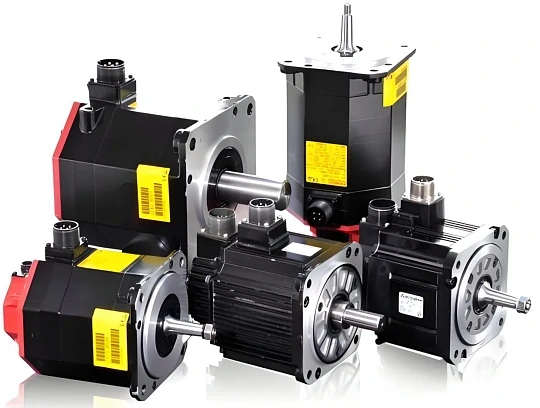

Complete Guide to Servo Motors: How They Work, Applications, and Precision CNC Housing Machining What is a Servo Motor? A servo motor operates through the principles of electromagnetism, where a generated energy field powers the rotor. Over time, continuous advancements have transformed these devices from auxiliary drives into reliable main drives for a wide range of industrial applications. Today, a modern servo motor features a compact, space-saving design, offers flexible adaptability, and enables highly dynamic and precise operations. As a result, businesses can achieve more efficient, accurate, and scalable automation processes by integrating these motors into their systems. What Are the Key Advantages of Servo Motors in Industrial Automation? Enhanced Precision and Accuracy […]

Industrial Automation Supplier & Parts Solutions for Global Manufacturing What Are Industrial Automation Parts? Industrial automation parts encompass a broad range of electrical and electronic components designed to control, monitor, and automate machines, production lines, and industrial processes across factories, warehouses, and manufacturing plants. In today’s competitive manufacturing environment, businesses increasingly rely on industrial automation parts to streamline operations and reduce dependency on manual labor. As a result, these components play a critical role in helping manufacturers improve process consistency, enhance workplace safety, and significantly increase production output—all while maintaining stable performance. Moreover, when integrated into a complete automation system, these parts work together to ensure continuous, uninterrupted operation. This is especially […]

Industrial Machinery and Manufacturing Equipment: Components, Types, and Applications What is Industrial Machinery? Industrial machinery is a collective term for a wide range of machine tools, industrial machinery components, and manufacturing equipment designed for use in manufacturing and industrial environments. In practice, manufacturers rely on industrial machinery in large-scale production settings to carry out specific operations and deliver consistent product output. As a result, it effectively replaces manual labor when handling heavy, complex, or high-risk tasks, while simultaneously improving production efficiency and overall quality. Moreover, industrial machinery plays a critical and irreplaceable role in modern industrial production. It covers everything from basic mechanical tools to highly automated production lines and robotic systems. At […]

Tight Tolerance Machining: How to Achieve High-Precision CNC Parts What is Tight tolerance machining ? In modern manufacturing, machining tolerance refers to the allowable variation in a part’s physical dimensions, usually expressed as plus or minus values from the nominal size. When components are produced with extremely minimal deviation—often within thousandths of an inch or even microns—they are considered to have tight tolerances. In CNC machining, this level of precision means dimensional variations can be as small as ±0.001 inches (25 microns) or even tighter, depending on the application, material, and part geometry. Achieving tight machining tolerances requires advanced CNC equipment, skilled operators, and strict process control, but the payoff is significant. Precision parts […]