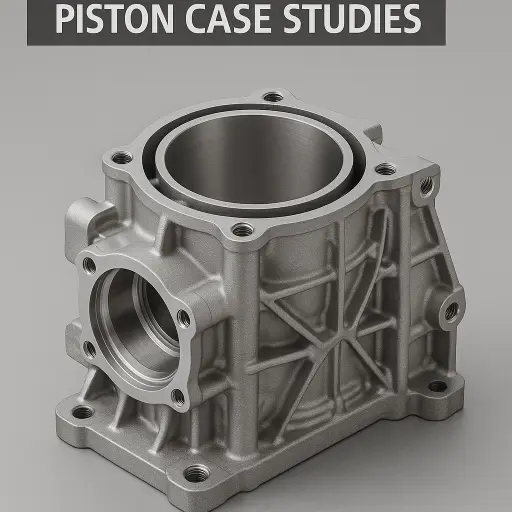

Aluminum Engine Component Case Studies Key Properties of Aluminum for Engine Applications Lightweight / Low Density: Aluminum Engine Component Case Studies show significant reductions in part and vehicle weight compared to traditional cast iron, leading to better fuel economy and improved handling dynamics. High Thermal Conductivity: Facilitates efficient heat dissipation from the engine, improving thermal efficiency and allowing for higher performance designs. Good Castability: Easily formed into complex shapes using processes like die casting and gravity casting. Good Machinability: Relatively easy to machine to precise tolerances. Good Corrosion Resistance: The naturally forming oxide layer provides inherent protection. High Recyclability: Aligns with sustainability goals. Challenges: Relatively lower high-temperature strength, higher coefficient of thermal expansion, and potential wear […]

カテゴリーアーカイブ: Study Cases

Aluminium Cars: Practical Insights for Automotive Professionals Aluminium cars—once a niche innovation—are now widely adopted in modern vehicle design for their strength-to-weight benefits. For engineers, buyers, and decision-makers in the automotive supply chain, understanding aluminum cars is essential when selecting materials, evaluating designs, or sourcing aluminum automotive components. This article offers Aluminium Cars: Practical Insights for Automotive Professionals, helping you make informed decisions across design, engineering, and procurement. This article answers common questions about aluminium cars, with practical insights and examples to support your sourcing and development decisions. What Are Aluminium Cars? Aluminium cars refer to vehicles that use aluminum extensively in their structural frame, body panels, or key components such […]

Technical Ceramics: Alumina for Electronics, Medical, and More Technical ceramics have emerged as vital materials in a wide array of high-performance applications, and alumina (aluminum oxide) stands out as a key player among them. Its unique combination of properties makes it indispensable in electronics, medical devices, and beyond. This article delves into the world of alumina ceramics, exploring their properties, processing techniques, applications, and advantages, especially in the electronics and medical fields. What are Technical Ceramics? Engineers design technical ceramics as advanced ceramic materials with specific performance characteristics. Unlike traditional ceramics, manufacturers precisely control their composition, microstructure, and processing, resulting in enhanced mechanical, thermal, electrical, and chemical properties. Industries widely […]

Alumina Carbide Applications: Aerospace, Automotive & More Alumina carbide, often used as a general term referring to composites or mixtures containing aluminum oxide (alumina) and carbon, or even aluminum carbide (Al₄C₃) itself, represents a class of advanced materials with immense potential across diverse industries. While the term “alumina carbide” can be loosely used, understanding the specific composition and properties of the material in question is crucial. Whether it’s a carefully engineered alumina-carbon composite, aluminum oxycarbide (Al₂CO), or pure aluminum carbide, these materials exhibit a unique combination of characteristics making them indispensable in demanding applications, particularly in aerospace, automotive, and manufacturing. This article will delve into the world of alumina carbide […]

Motor Shaft Manufacturer: Ensuring High-Quality Performance Motor shafts are integral components of various machinery, including electric motors, generators, and industrial equipment. The quality and functionality of a motor shaft are crucial for the overall performance of the machinery it is part of. In this article, we’ll explore the different aspects of motor shafts, including their types, materials, manufacturing processes, and the key considerations for choosing a reliable motor shaft manufacturer like Welleshaft. Introduction Introduction to Motor Shafts Motor shafts serve as the connecting link between the motor and the driven equipment, transmitting power and torque. They come in various shapes and sizes to suit different applications, and the choice of […]