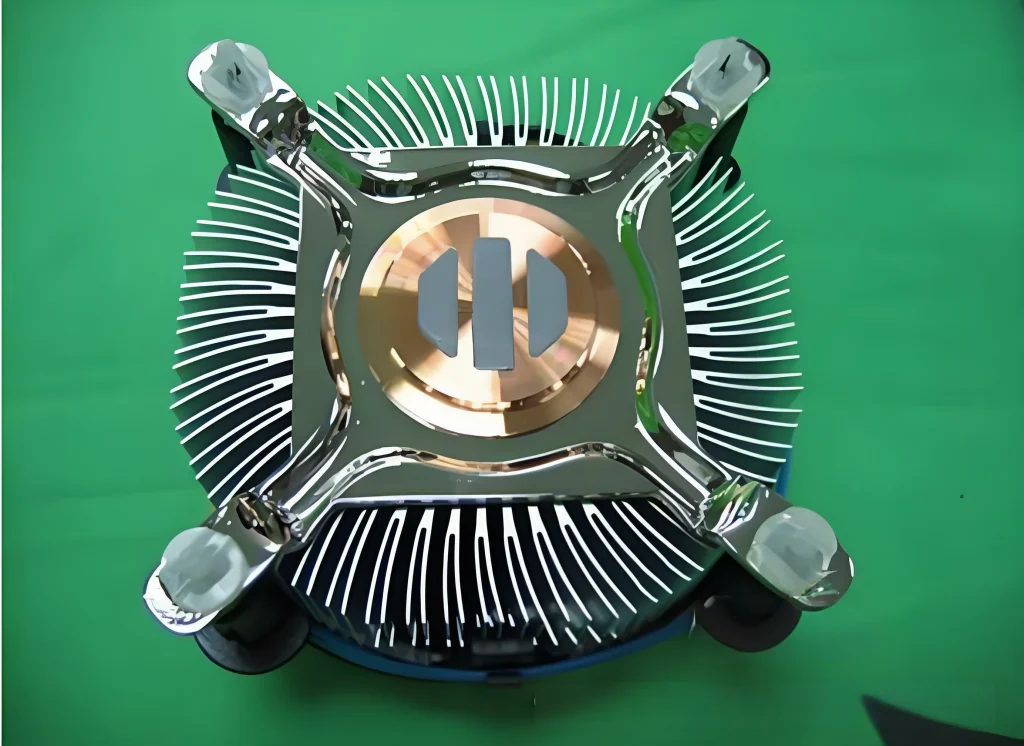

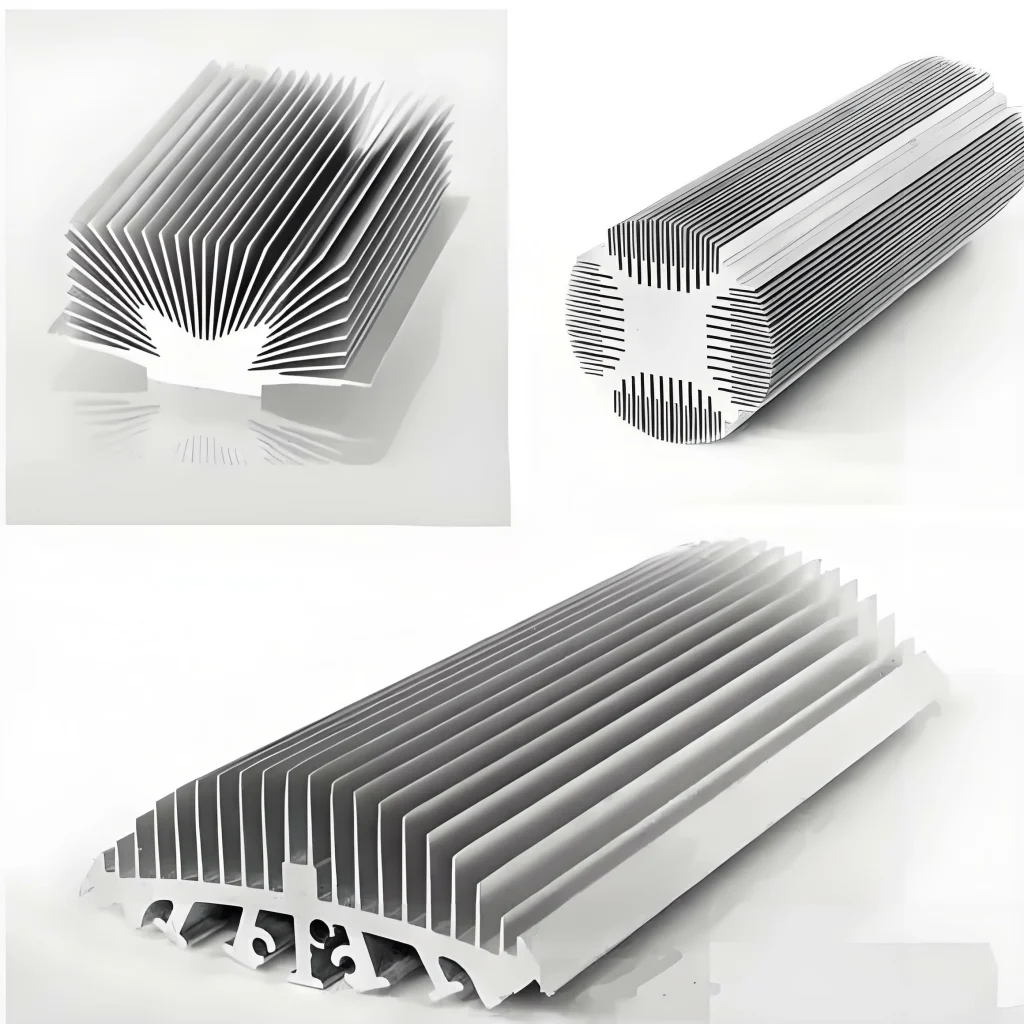

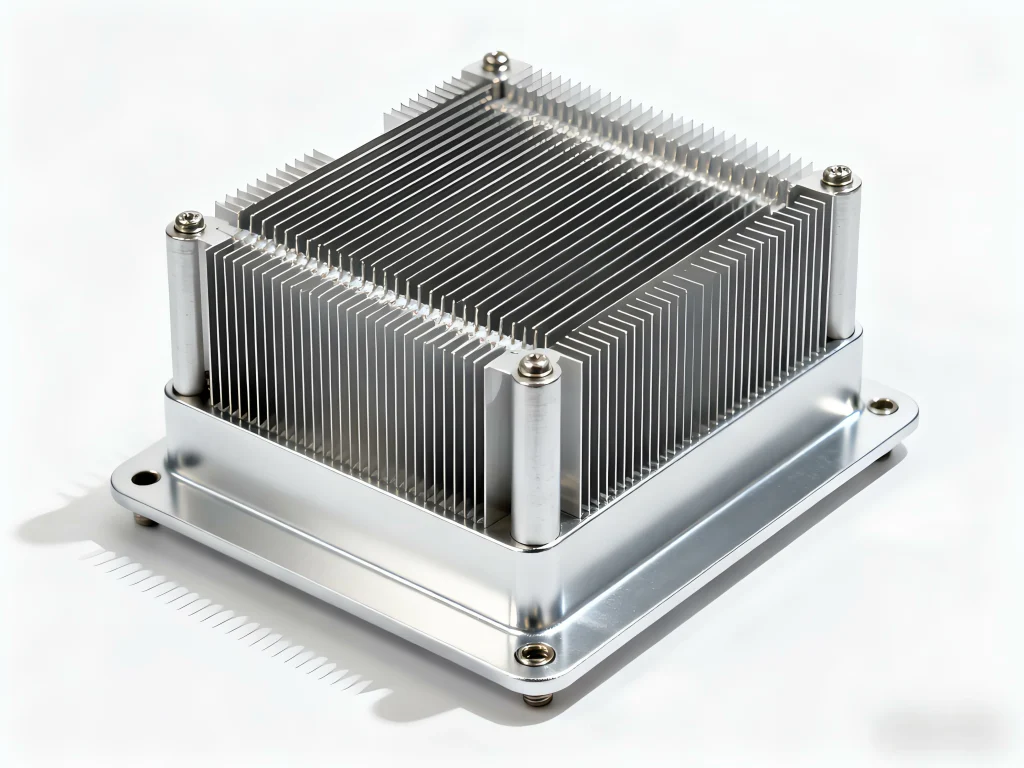

Aluminum vs Copper Skived Heatsinks in China: Cost & Performance When it comes to skived fin machining and skived heatsink production, engineers and procurement managers often face a critical decision in Aluminum vs Copper Skived Heatsinks: whether to select aluminum skived heatsinks for compact PCB cooling or copper skived fin heat sinks for high-current devices. Understanding the skiving process, skived fin technology, precision skiving heat sink design, and thermal conductivity of skived heat sinks is essential for making informed decisions and avoiding costly production issues. Pain Points in Aluminum vs Copper Skived Heatsinks in China Thermal Performance Challenges Aluminum skived heatsinksmay struggle under high thermal loads; copper skived fin heat […]

カテゴリーアーカイブ: Study cases and knowledge

業界のトレンド、ケーススタディ、ハウツーガイドをご覧ください、 製造工程 ウェルシャフトのナレッジハブでは、エンジニアやソーシングプロフェッショナルのための専門的な見識やFAQを提供しています。

Welleshaftの研究事例とナレッジのページでは、主要な調達課題、品質管理のハードル、実際の製造上の問題点を取り上げています。

How to Ensure Defect-Free Large-Scale Casting Alloys in China In industrial production, achieving defect-free large-scale casting alloys in China remains one of the most demanding challenges for OEMs, industrial buyers, and heavy machinery producers. Companies involved in precision casting alloys manufacturing or industrial casting alloy production often face issues such as porosity, dimensional deviation, and inconsistent alloy composition. These defects not only increase rejection rates but also cause production delays, higher costs, and brand reputation damage—particularly in automotive casting alloy manufacturing and high-strength alloy casting manufacturing for export projects in China and beyond. Customer Pain Points in How to Ensure Defect-Free Large-Scale Casting Alloys in China Imagine an automotive OEM sourcing large-scale casting alloy manufacturers […]

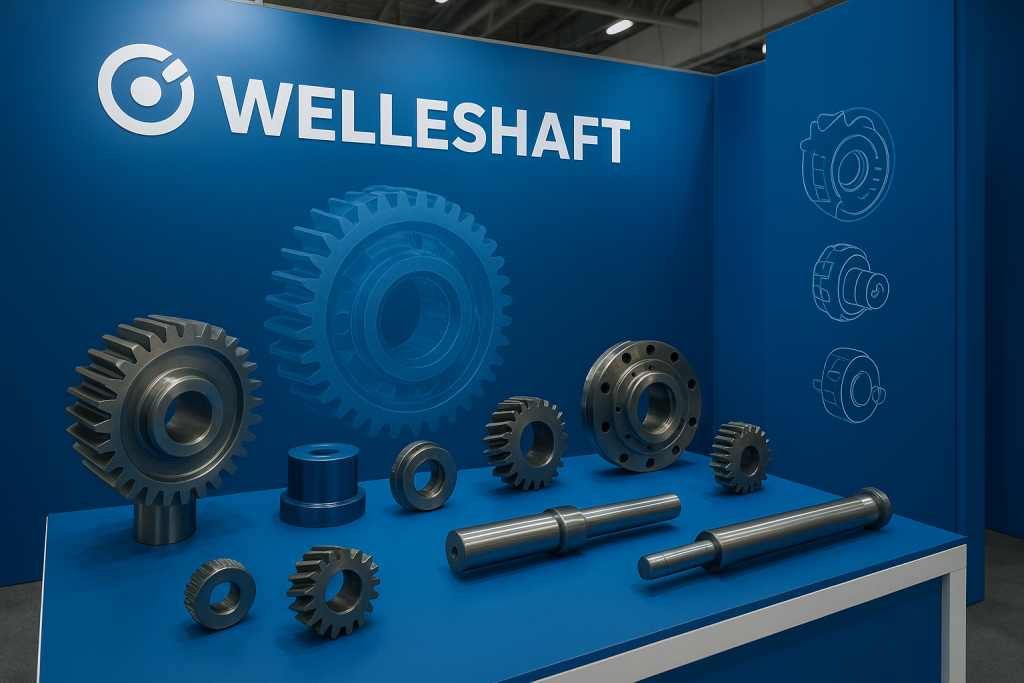

Custom Worm Gear Manufacturing for Automotive Applications: How OEMs Solve Quality and Delivery Delays in China In today’s competitive automotive supply chain, custom worm gear manufacturing: how OEMs solve quality and delivery delays in China plays a critical role in ensuring reliability, reducing noise, and maintaining consistent torque performance. For OEMs, Tier-1 suppliers, and exporters, choosing the right worm gear manufacturer from China or factory direct worm gear supplier can determine the success of an entire vehicle platform. Welleshaft engineers note that worm gear manufacturing affects delivery, warranty costs, and brand reputation, especially for OEM automotive components. Pain Points in Precision Automotive Worm Gear Manufacturing: How OEMs Solve Quality and Delivery Delays in […]

Custom Skived Fin Heatsink Manufacturing Services When sourcing a custom skived fin heatsink manufacturer in China, Many buyers face challenges such as inconsistent thermal performance, long lead times, and unclear cost structures. Understanding How to Choose a Reliable Skived Fin Heatsink Manufacturer in China is essential when selecting a factory-direct supplier for the USA market or securing skived fin heat sink OEM services for industrial electronics. The process often involves navigating both technical and management hurdles—from ensuring skiving process precision to making the right material selection between copper skived fin heat sinks and aluminum skived fin heat sinks. This guide explains how to choose a reliable skived fin heatsink manufacturer […]

Buy Non-Ferrous Castings Alloy from China for Industrial Use Looking to buy non-ferrous castings alloy from China for industrial applications? Many industrial buyers face challenges sourcing high-quality, precision components for machinery and equipment. Partnering with a China non-ferrous castings alloy supplier for USA / Germany / Brazil markets or an industrial non-ferrous castings alloy manufacturer with 10+ years exporting experience ensures reliable delivery, consistent quality, and cost-effective solutions. Experienced manufacturers also provide custom non-ferrous castings alloy for industrial machinery and equipment, OEM non-ferrous castings alloy manufacturer services in China for global buyers, and high-precision non-ferrous castings alloy for industrial use, helping clients streamline production and reduce risks. Common Pain Points in Non-Ferrous Castings […]

How to Choose the Best Worm Gear Supplier in China for Your Project? Selecting a worm gear supplier from China for your industrial or automotive projects can make or break your production schedule, product quality, and overall cost. From precision worm gear manufacturing for UK automotive parts to high-precision worm gear production companies in China for European markets,Choosing the right partner is crucial. To choose the best worm gear supplier in China for your project, it is essential to understand how to evaluate a Chinese worm gear manufacturer, as many companies struggle with delayed lead times, inconsistent quality, or hidden costs when sourcing from China. Common Pain Points When Sourcing Worm Gears […]

Custom Skived Heat Sink Prototyping and Small-Batch Production In modern electronics and high-performance devices, skived fin machining, skived heatsink manufacturing, and precision skiving heat sink techniques are essential for effective thermal management. Engineers often ask “How to Get Custom Skived Fin Heatsinks from China for Rapid Prototypes?” when seeking custom skived fin heatsink prototype services or small-batch skived heatsink manufacturing. These teams frequently face challenges balancing thermal performance, low-volume production, and rapid delivery. Whether it’s rapid prototyping for skived heat sinks or high-precision skived heatsink prototyping, mastering the skiving process / skived fin technology is key to reliable results. Pain Points in Skived Fin Heatsink Manufacturing and Prototyping Limited Supplier Options for Custom Skived Heatsink […]

High-Strength Alloy Casting Solutions In today’s global supply chain, high-strength alloy casting manufacturing has become a critical process for industries that require durable, precision-engineered, and certified parts. From automotive to machinery and oil & gas, companies depend on custom alloy casting manufacturing and non-ferrous alloy casting manufacturing to achieve performance and safety standards defined by ASTM, GB, and ISO. Yet many buyers—whether sourcing from a casting alloys supplier from China or working with a regional partner—face recurring challenges: inconsistent quality, rising production costs, and supply delays. Pain Points in High-Strength Alloy Casting Manufacturing Critical component failures: Automotive OEMs using low-grade alloys report frequent part replacements. Instead of high-performance alloy casting for automotive and machinery, […]

Welleshaft sincerely invites you to visit us at the 2025 Asia International Power Transmission and Control Technology Exhibition (PTC ASIA 2025). We warmly welcome you to our booth to discuss the latest industry trends and explore our high-performance mechanical components and custom-engineered shaft solutions face-to-face. 📍 Exhibition Information Date: October 28–31, 2025 Venue: Shanghai New International Expo Centre Booth No.: Hall E7, E7-H5 As a leading manufacturer of mechanical components, transmission parts, shafts, and customized engineering solutions, Welleshaft delivers precision-engineered products for OEMs, industrial manufacturers, and engineering firms worldwide. Our solutions ensure high performance, durability, and compliance with international standards. At the exhibition, you will experience our core products and […]

High-Performance Skived Heatsink Manufacturing and Precision Fin Machining | Welleshaft What is Skived Fin Machining and High-Performance Skived Heatsink Manufacturing? Skived Heatsink Manufacturing and Precision Fin Machining are critical for efficient thermal management in electronics, automotive, LED, and telecom applications. Welleshaft specializes in precision skived fin fabrication, copper and aluminum skived fin heat sinks, and high-density skived fins to maximize thermal conductivity. Our end-to-end Skived Heatsink Manufacturing and Precision Fin Machining production ensures reduced thermal resistance, consistent quality, and compliance with ISO/ASTM/GB standards. Learn more about our precision skived fin machining solutions. The Skiving Process in Precision Skived Fin Heat Sink Fabrication Overview of Skived Fin Technology for High-Performance Heatsinks […]