Medical Grade & Surgical Stainless Steel | Custom SS455 PER ASTM F899 Solutions Precision, durability, and reliability drive success in the medical and surgical fields. Manufacturers rely on medical-grade stainless steels—especially SS455—to meet the strict standards of surgical instruments and implants. By adhering to ASTM F899 standards, engineers design custom stainless steel solutions like SS455 to endure the demanding medical environment, delivering corrosion resistance, biocompatibility, and exceptional strength. This article highlights the unique properties of SS455 and introduces Welleshaft as a trusted global supplier and contract manufacturer for custom stainless steel solutions. Section 1: Understanding Medical Grade Stainless Steel: Custom SS455 per ASTM F899 Stainless steel plays a key role […]

カテゴリーアーカイブ: Study cases and knowledge

業界のトレンド、ケーススタディ、ハウツーガイドをご覧ください、 製造工程 ウェルシャフトのナレッジハブでは、エンジニアやソーシングプロフェッショナルのための専門的な見識やFAQを提供しています。

Welleshaftの研究事例とナレッジのページでは、主要な調達課題、品質管理のハードル、実際の製造上の問題点を取り上げています。

Expert Titanium Forging Services | Precision & Quality in Metal Forging Titanium forging is a specialized process that transforms raw titanium into high-performance components used across various industries. Renowned for its strength, light weight, and resistance to corrosion, titanium is an ideal material for aerospace, medical, and industrial applications. In this article, we’ll explore the intricacies of titanium forging, focusing on the expertise required to deliver precision and quality. We’ll also highlight Welleshaft as a trusted global supplier and contract manufacturer offering expert Titanium Forging Services. Section 1: Understanding Titanium Forging: The Basics Titanium forging involves shaping titanium alloys into components using compressive forces. The process enhances the material’s mechanical […]

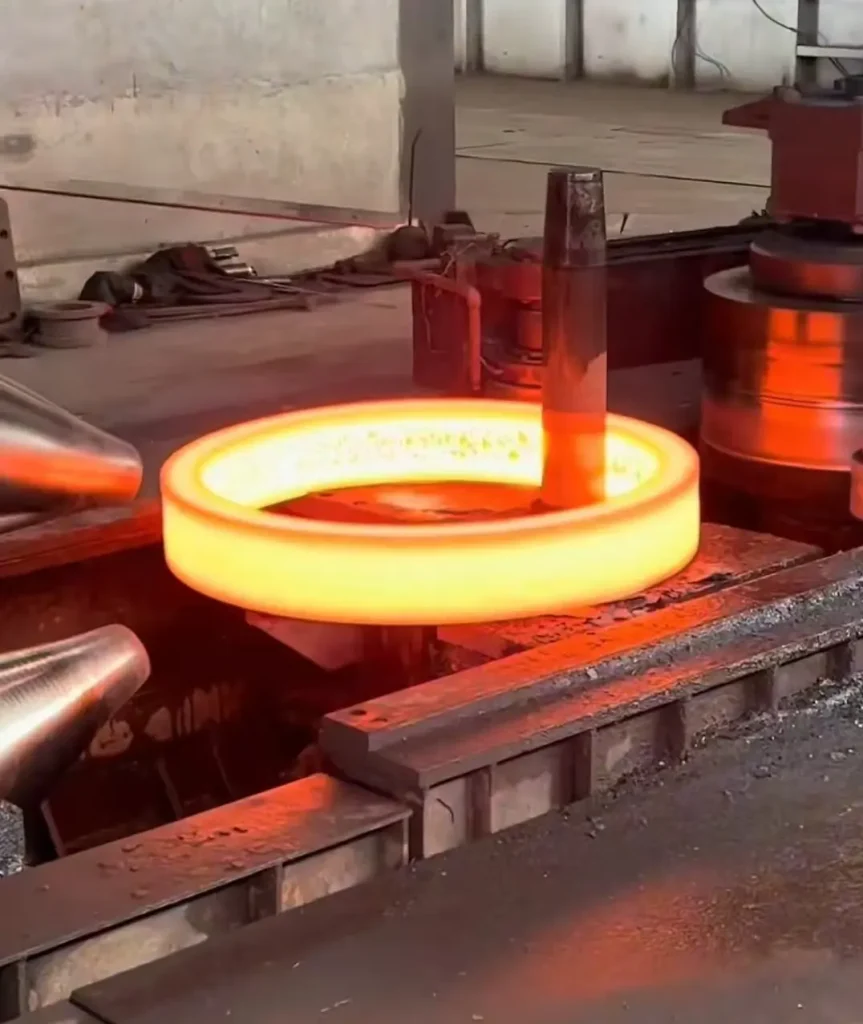

Rill Rolling for Sale: A Comprehensive Guide to Ring Rolling and Rolled Ring Forging Rill rolling might not be a widely recognized term, but it often refers to the detailed and technical aspects of ring rolling and rolled ring forging. These processes are pivotal in creating high-quality metal rings used across various industries. This article provides an in-depth look into these manufacturing techniques, their processes, and considerations for purchasing rolled rings. Section 1: Introduction 1.1. What is Rolled Ring Forging? Rolled ring forging is a manufacturing process used to create high-strength, precision-engineered rings. It involves heating a metal billet to a malleable state and then shaping it into a ring using […]

Brass Forging: A Comprehensive Guide Brass forging is a crucial process in manufacturing high-quality brass components used across various industries. Whether you’re a manufacturer, engineer, or hobbyist, Brass Forging: A Comprehensive Guide will help you understand the benefits of forged brass parts. In this article, we explore everything you need to know about brass forging, including the differences between hot and cold forging, and key considerations when purchasing forged brass products. Frequently Asked Questions (FAQs) about Brass Forging 1. What is brass forging? Brass forging is a metalworking process where brass is shaped using compressive forces. This Brass Forging: A Comprehensive Guide explains how heating the brass makes it more […]

Dear Valued Customers, As the Mid-Autumn Festival approaches, we want to extend our heartfelt wishes for peace, prosperity, and happiness to you and your family during this festive season. May the full moon bring harmony and joy to your home. At Welleshaft, we deeply appreciate your continued trust and support. We remain committed to providing innovative solutions for your business with our broad range of high-quality products. Our expertise covers: Wear-resistant and corrosion-resistant materials for demanding environments. Special alloys components tailored for durability and performance. Rubber and plastic components designed for various industrial applications. Non-ferrous metals components crafted for precision and reliability. Standard mechanical components, fasteners, and core transmission parts […]

Customer Satisfaction Feedback: The Key to Success in Contract Manufacturing In the fast-evolving world of manufacturing, customer satisfaction is the driving force behind business growth. For industries relying on contract manufacturing, ensuring customer needs are met is crucial to success. From CNC machining manufacturers to medical device contract manufacturing and cosmetics contract manufacturing, maintaining high levels of satisfaction through precision, quality, and reliability is essential. In this article, we will explore the importance of customer feedback in the manufacturing industry, how it can help improve services, and why Welleshaft stands out as a trusted global supplier and contract manufacturer. The Role of Customer Satisfaction in Contract Manufacturing Customer satisfaction is […]

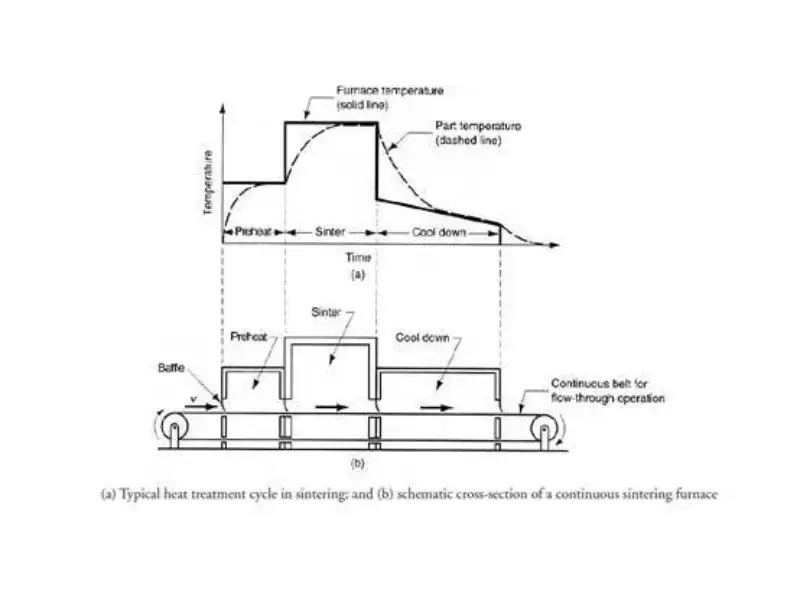

Advanced Powder Metallurgy Techniques & Applications | Precision Metal Forming Precision metal forming has been significantly advanced by the development of powder-based manufacturing technologies. This process has revolutionized the manufacturing industry by enabling the production of complex and high-performance components with exceptional precision and efficiency. This article explores the advanced techniques and applications of this method, emphasizing its role in precision metal forming across automotive, medical, electronics, and other high-demand sectors. We will delve into the process of sintering in metallurgy, examine the benefits of this technology, and explain why it remains a critical process in various industries. Section 1: Introduction 1.1. What is Powder Metallurgy? Modern manufacturers have enhanced precision […]

Section 1: Introduction to Metal Sintering Metal sintering is a pivotal process in manufacturing precision components, utilizing powdered metals to create durable and complex parts. This article explores the various facets of metal sintering, highlighting its applications, benefits, and the expert metal sintering services offered by Welleshaft as a leading global supplier in this field. 1.1. Understanding the Metal Sintering Process Metal sintering involves compacting and forming metal powders under controlled temperatures and pressures. Through expert metal sintering services, this process produces sintered metal parts that exhibit high strength, precision, and often intricate geometries that traditional manufacturing methods struggle to achieve. Section 2: Types of Metal Sintering Processes Metal sintering encompasses […]

High-Performance Sintered Bearings | Durable & Efficient Solutions for All Applications In today’s demanding industrial environment, selecting the right bearing type is crucial to ensure the reliability, efficiency, and longevity of machinery and equipment. High-performance sintered bearings are among the most sought-after solutions, known for their durability, self-lubricating properties, and versatility. In this article, we’ll explore the benefits of these bearings, delve into their applications, and highlight why Welleshaft stands out as a trusted global supplier and contract manufacturer of these high-performance components. Section 1: What is a Sintered Bearing? High-performance sintered bearings are produced through a process known as sintering, which involves compacting metal powders under high pressure and […]

High-Performance Sintered Gears: Durable & Precise Gear Solutions In the world of precision engineering, manufacturers rely on High-Performance Sintered Gears for their exceptional durability and efficiency. By using powder metallurgy, they produce gears that combine superior strength with cost-effectiveness, setting them apart from traditionally machined gears. In this article, we explore the advantages of High-Performance Sintered Gears, explain how manufacturers create them, and highlight why Welleshaft is your ideal partner for top-tier sintered gear solutions. Section 1: What Are Sintered Gears? Sintered gears are components created through a process known as powder metallurgy. This method involves compressing powdered metal into a mold and then heating it to a temperature where […]