Stainless Steel Fasteners: Types, Grades, and Uses What Are Stainless Steel Fasteners and Their Types? When you’re building or fixing anything—from furniture to outdoor projects to boats—stainless steel fasteners (or ss fasteners) are usually the safest bet. They’re tough, resist rust extremely well, and come in all kinds of options like bolts, nuts, washers, studs, and specialty screws. At the end of the day, stainless steel fastners are essentially low-carbon steel with at least 10% chromium added, and it’s this chromium that provides the corrosion resistance everyone relies on. That’s why grades like 304 (general use) and 316 (marine use) are so popular. For harsher environments such as marine work, […]

カテゴリーアーカイブ: Study cases and knowledge

業界のトレンド、ケーススタディ、ハウツーガイドをご覧ください、 製造工程 ウェルシャフトのナレッジハブでは、エンジニアやソーシングプロフェッショナルのための専門的な見識やFAQを提供しています。

Welleshaftの研究事例とナレッジのページでは、主要な調達課題、品質管理のハードル、実際の製造上の問題点を取り上げています。

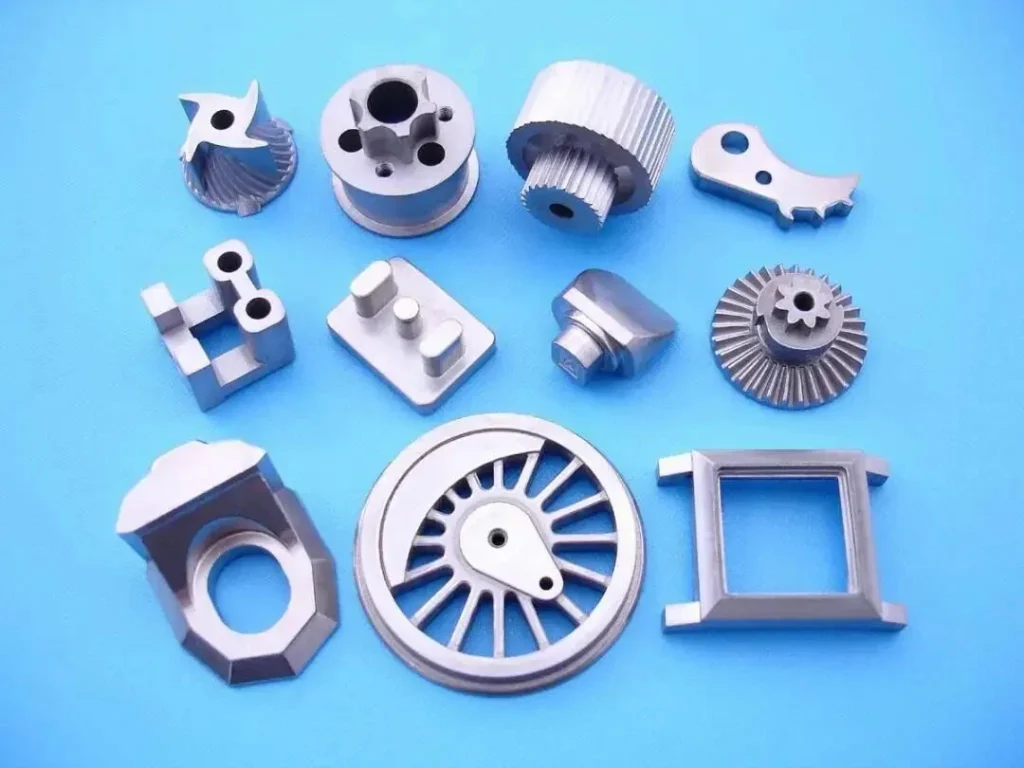

Powder Injection Molding (PIM) for Precision Metal Parts What Is Powder Injection Molding and How Does It Work? Powder Injection Molding (PIM)—also known as powder injection moulding—is essentially the metal or ceramic version of plastic injection molding. Instead of using polymer pellets, the process uses a mixture of fine metal powder + binder, creating an injectable feedstock that can be molded into complex shapes. The workflow is straightforward but highly engineered: Feedstock compounding – Metal powder and polymer binders are mixed to form injection molding powder. Injection molding – The feedstock is injected into a mold using a powder molding machine or metal injection molding machine. Debinding – The binder is removed through […]

The 8 Most Common Questions about metal injection molding – Asked and Answered How does metal injection molding compare to other manufacturing methods? Metal injection molding (MIM) combines the design freedom of plastic injection molding with the strength of metals, making it perfect for high-precision parts that are tough to produce with CNC machining or die casting. It excels at producing complex, net-shape components—even sub-gram parts that fit in your palm. MIM delivers intricate shapes with strong mechanical properties and consistent quality at high volumes, while simpler parts remain cheaper with press-sinter, turning, or stamping. For businesses aiming to cut waste, boost efficiency, and reliably make precision components, MIM is […]

Metal Injection Molding Manufacturer: Choosing the Right Supplier for Quality and Compliance What Are MIM Parts and Why Are They Important? Metal Injection Moulding (MIM) parts are small to medium-sized metal components produced by metal injection moulding companies using fine metal powders combined with injection molding. Unlike traditional machining or casting, MIM enables complex shapes, tight tolerances, and consistent material properties, making it the ideal solution for industries that demand high-performance, precision components. MIM reduces machining time, minimizes waste, and eliminates assembly for intricate parts. It’s widely used in medical devices, electronics, automotive components, and aerospace parts. Companies adopting MIM benefit from reduced production costs and the ability to deliver […]

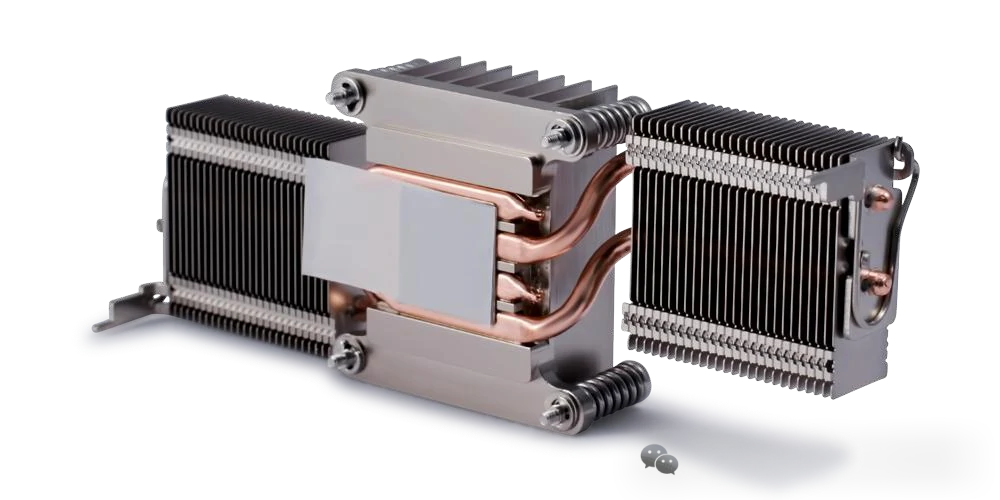

What is a Skived Fin Heat Sink? High-Performance Skived Fin Heat Sinks are high-performance thermal solutions designed to maximize heat dissipation in compact electronics. Unlike standard heat sinks, High-Performance Skived Fin Heat Sinks feature precision-cut fins from a single metal block, providing superior thermal conductivity and structural integrity.Engineers often ask, “What is a Skived Fin Heat Sink?” Welleshaft offers High-Performance Skived Fin Heat Sink Supplier services for LEDs, GPUs, and automotive modules, ensuring consistent thermal performance and system reliability. Principle and Skiving Process Workflow The Skiving Process slices fins from solid aluminum or copper blocks using CNC-controlled skiving machines. Fins are simultaneously formed and bent to the required angle, maintaining uniform thickness (0.1–0.3 […]

Which Metal Injection Molding Machines and MIM Equipment Are Best for High-Precision MIM Molding? What Are MIM Machines and What Types Exist? What Are MIM Machines? Metal Injection Molding Machines for Metals, or MIM machines, shape powdered metals mixed with polymer binders into precise parts via mim molding. Unlike traditional machining, which removes material, MIM is additive, enabling complex geometries that are otherwise hard to achieve. High-quality MIM equipment & machinery produces dense, high-strength parts from stainless steel, aluminum, titanium, and alloy steels. This capability is essential for micro components, medical implants, or automotive parts where tight tolerances, repeatability, and reliable performance are critical. Common Types of Metal Injection Molding […]

Metal Injection Molding Parts: MIM Casting & Machining What is Metal Injection Molding Parts? Metal Injection Molding(MIM) parts are high-precision metal parts made using the metal injection molding process, ideal for complex geometries, thin walls, and high-volume production. Using MIM steel, mim aluminum, and injection molded titanium, this micro metal injection molding technique outperforms traditional machining of metal parts, die casting, MIM manufacturing, offered by metal injection molding companies and suppliers, ensures tight tolerances, excellent strength, and minimal waste, making it perfect for medical, automotive, electronics, and industrial applications. When comparing MIM Casting vs Machining, MIM stands out for its ability to produce highly complex, precise parts efficiently and cost-effectively. What is CNC Machining? […]

MIM Materials | What Types of Metals Can Be Used in MIM? What Is Metal Injection Molding (MIM)? Metal Injection Molding (MIM), also called metal injection moulding or powder injection moulding (PMIM), produces small, complex metal parts with high precision. Engineers mix metal powders with binders, inject them, then debind and sinter the parts using various Metal Injection Molding (MIM) Materials to create strong, high-performance components.high-performance components. This metal injection molding process allows for mass production of intricate components that would be difficult or costly to make with traditional machining.Engineers use metal injection molding (MIM) materials like steel, titanium, and micro metals to create durable, high-performance parts with excellent repeatability, […]

MIM Process Explained: From Defect Control to Process Optimization What Is MIM? Metal Injection Molding(MIM) — also known as metal injection moulding — is an advanced manufacturing method that merges powder metallurgy with plastic injection molding. By injecting fine metal powders mixed with polymer binders into precision molds, MIM allows for mass production of complex metal parts with tight tolerances and minimal waste. The resulting MIM parts achieve near-wrought mechanical strength, making them ideal for industries such as automotive, medical devices, electronics, and industrial machinery. What is the metal injection molding process? Metal injection molding (MIM) combines the best of two worlds—the precision of powder metallurgy and the flexibility of plastic injection molding. It’s designed for […]

How Can USA & Germany Manufacturers Avoid Costly Worm Gear Defects? | Welleshaft Ensuring top-quality worm gear manufacturing is critical for industrial, automotive, and heavy-duty applications. Defective worm gears can cause costly production delays, equipment failures, and brand reputation loss. At Welleshaft, we specialize in precision worm gear manufacturing, custom worm gear inspection, and high-precision worm gear production for OEM manufacturers worldwide. How Can USA & Germany Manufacturers Avoid Costly Worm Gear Defects? Our professional worm gear manufacturing services in China help clients prevent common issues such as pitting, surface wear, dimensional deviations, and assembly misalignments. By leveraging advanced worm gear manufacturing techniques and custom worm gear inspection and quality control […]

-materials-welleshaft.webp)