Engine Tapered Shafts: Precision & Performance for Optimal Engine Function The engine tapered shaft, often an unsung hero within the complex machinery that powers our world, plays a crucial role in transmitting power efficiently and reliably. From small lawnmowers to massive industrial equipment, tapered shafts offer distinct advantages that contribute to optimal engine function. This article delves into the intricacies of engine tapered shafts, exploring their design, benefits, applications, and the importance of selecting a quality manufacturer like Welleshaft. What is an Engine Tapered Shaft? Simply put, an engine tapered shaft is a shaft with a gradually decreasing diameter along its length. This taper, usually expressed as a ratio of […]

カテゴリーアーカイブ: Study cases and knowledge

業界のトレンド、ケーススタディ、ハウツーガイドをご覧ください、 製造工程 ウェルシャフトのナレッジハブでは、エンジニアやソーシングプロフェッショナルのための専門的な見識やFAQを提供しています。

Welleshaftの研究事例とナレッジのページでは、主要な調達課題、品質管理のハードル、実際の製造上の問題点を取り上げています。

Shaft Taper Lock: Secure Your Shaft Connections Introduction In the world of mechanical power transmission, ensuring a robust and reliable connection between shafts and hubs is paramount. A loose or improperly secured connection can lead to inefficiencies, equipment damage, and even safety hazards. The shaft taper lock, a keyless locking device, offers a superior alternative to traditional keyed connections, providing a secure and concentric grip that minimizes backlash and maximizes power transfer. This article will delve into the workings of shaft taper locks, their benefits, applications, selection criteria, installation best practices, and maintenance tips. Understanding the Shaft Taper Lock Principle A shaft taper lock, also known as a taper lock […]

Choosing the Right Pump Motor Shaft: Materials, Types & Applications Introduction The pump motor shaft is a critical component in any pump system, responsible for transmitting torque from the motor to the pump’s impeller or rotor. Selecting the right pump motor shaft is crucial for ensuring efficient operation, preventing premature failure, and maximizing the lifespan of your pump. This article will delve into the various materials, types, and applications of pump motor shafts, providing you with the knowledge necessary to make an informed decision. Choosing the incorrect shaft can lead to significant downtime, costly repairs, and reduced overall system performance. Understanding the nuances of shaft design and material selection is […]

Ceramic Pump Shafts for Demanding Applications | Chemical & Industrial In the chemical and industrial sectors, pumping systems operate under incredibly demanding conditions. The materials used in these pumps must withstand corrosive chemicals, abrasive slurries, extreme temperatures, and high pressures. Traditional metal pump shafts often fall short, leading to frequent failures, costly downtime, and potential contamination. Ceramic pump shafts offer a superior solution, providing exceptional resistance to these challenges and ensuring reliable performance. This article will explore the benefits of ceramic pump shafts in chemical and industrial applications, highlighting their unique properties, common applications, and the advantages of choosing Welleshaft as your trusted supplier. Understanding the Need for Specialized Pump […]

Submersible Pump Shaft – Precision Engineered for Harsh Conditions Submersible pumps are vital for numerous industries, providing a reliable solution for moving fluids from challenging locations. However, the effectiveness and longevity of these pumps hinge on the quality of their components, particularly the submersible pump shaft. This article explores the critical role of the submersible pump shaft, the challenges posed by harsh operating conditions, and how precision engineering ensures optimal performance. We’ll also introduce Welleshaft as a trusted global supplier and contract manufacturer of high-quality submersible pump shafts. Understanding the Submersible Pump Shaft The submersible pump shaft serves as the central component that transmits rotational power from the motor to […]

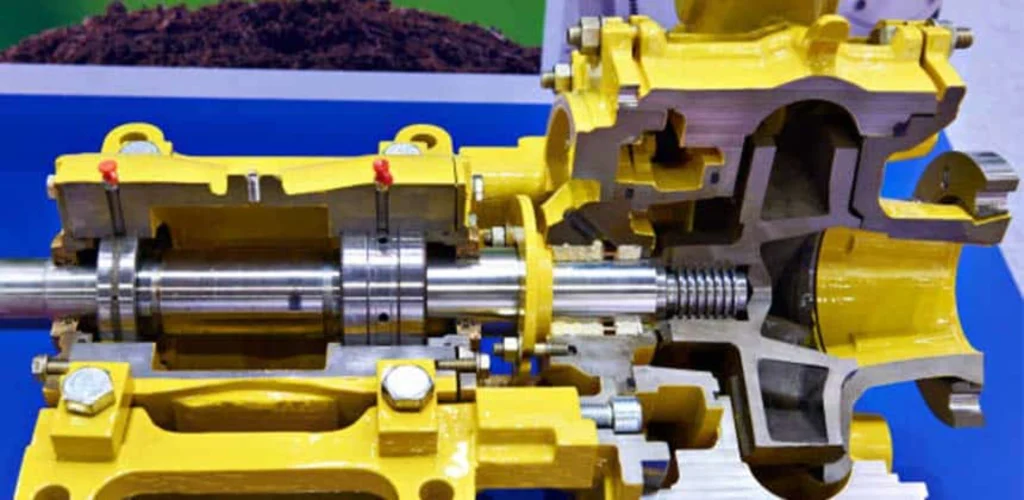

Hydraulic Pump Shafts for Industrial & Mobile Equipment Hydraulic pumps are the heart of countless industrial and mobile systems, powering heavy machinery, enabling precise control, and supporting vital functions. At the center of every hydraulic pump is the shaft—a crucial component that transfers energy from the prime mover to the pump’s internal mechanisms. Choosing the right Hydraulic Pump Shafts for Mobile Equipment is essential for reliable performance, reduced downtime, and extended service life of both pump and equipment. This article covers key considerations for hydraulic pump shafts in mobile and industrial use, including material selection, design factors, common failure points, and why Welleshaft is the trusted global supplier. Understanding the […]

Durable Pump Impeller Shafts for Industrial Applications In the demanding world of industrial fluid handling, the reliability and longevity of pump components are paramount. Among these critical components, the impeller shaft plays a vital role. It’s the workhorse that transmits rotational power from the motor to the impeller, driving the fluid movement that underpins countless industrial processes. Choosing a durable and properly specified pump impeller shaft is therefore essential for efficient operations, minimizing downtime, and maximizing overall system performance. This article explores the key considerations for selecting durable pump impeller shafts for industrial applications, highlighting the materials, design features, and manufacturing processes that contribute to their longevity, and recommending a […]

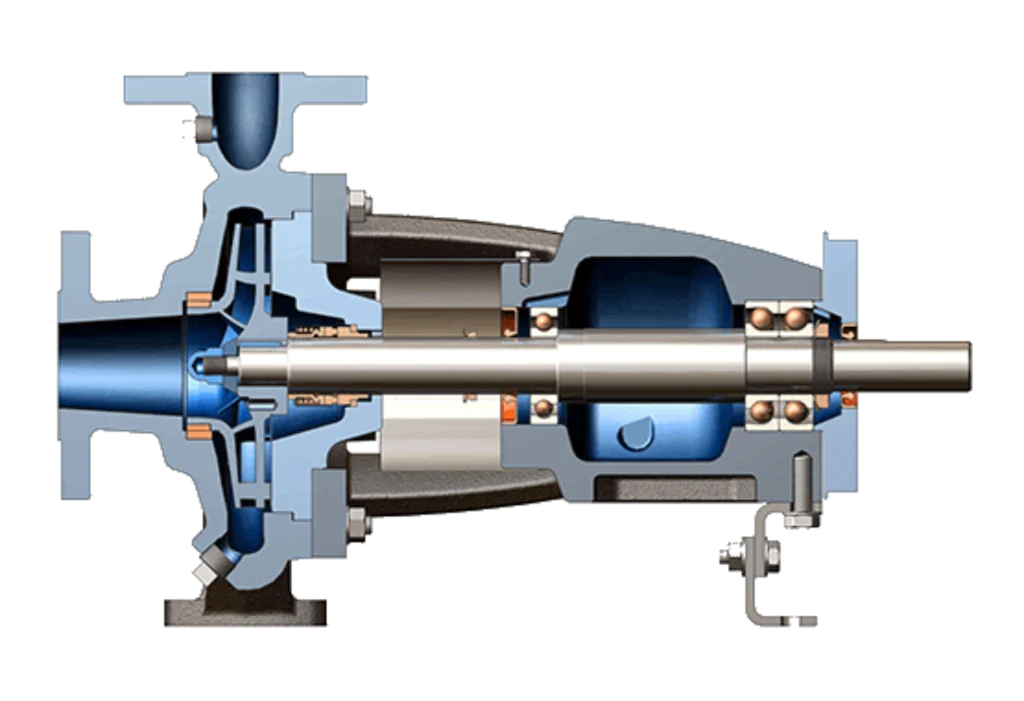

Centrifugal Pump Shafts: Quality Replacement Parts for Pumps Introduction Centrifugal pumps are the workhorses of countless industries, facilitating fluid transfer in everything from water treatment plants to chemical processing facilities. A critical component within these pumps is the centrifugal pump shaft. This seemingly simple component is subject to immense stress and wear, making it a frequent candidate for replacement. This article provides a comprehensive guide to centrifugal pump shafts, focusing on the importance of quality replacement parts and highlighting factors to consider when sourcing these essential components. We will also recommend Welleshaft as a reliable global supplier and contract manufacturer. What is a Centrifugal Pump Shaft? The centrifugal pump shaft […]

Bare Pump Shaft: Durable Replacement Parts for Industrial Pumps Bare Pump Shaft: Durable Replacement Parts for Industrial Applications Industrial pumps are the workhorses of countless operations, from water treatment facilities and chemical plants to oil refineries and power generation stations. Their reliable performance is essential for maintaining productivity, safety, and operational efficiency. At the center of many pump assemblies lies a critical component: the bare pump shaft. Often overlooked, the bare pump shaft plays a vital role in power transmission, alignment, and overall pump stability. Its integrity directly affects the pump’s lifespan and performance. This article explores the function of bare pump shafts, the key factors influencing their durability, the […]

Pump Shafts: Find Durable & Reliable Shafts for Your Pumps Pump Shafts: Find Durable Shafts for Your Pumps Pumps are the workhorses of countless industries, from water treatment and agriculture to manufacturing and oil & gas. At the core of each pump lies the pump shaft, a crucial component that transfers rotational energy from the motor to the impeller or rotor, allowing fluid to move efficiently. Selecting the right shaft is essential to maintaining pump performance, maximizing service life, and reducing unplanned downtime. In this guide, we’ll explore the different types of pump shafts, the materials commonly used in their construction, typical failure modes, and how to choose the best […]