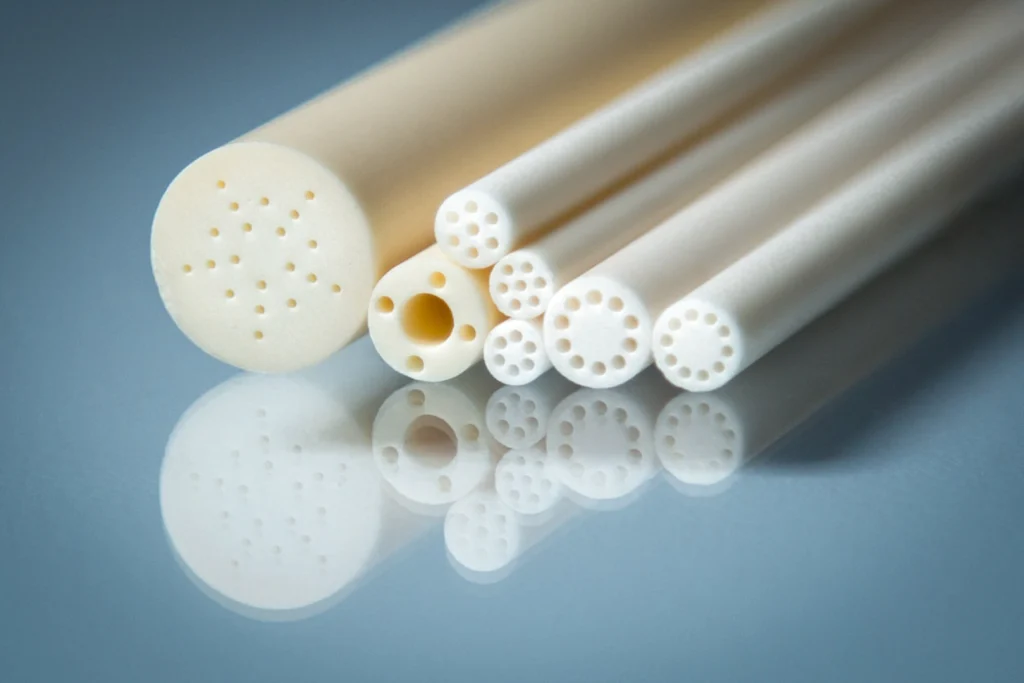

Thermocouple Protection Tubes – Aluminum Oxide (Al2O3) Introduction Accurate and reliable temperature measurement is crucial across a multitude of industries. Thermocouples, the workhorses of temperature sensing, are often exposed to harsh environments that can compromise their performance and longevity. Thermocouple protection tubes play a vital role in shielding the delicate thermocouple element from extreme temperatures, corrosive atmospheres, and mechanical abrasion. Aluminum Oxide (Al2O3), also known as alumina, is a widely preferred material for these protection tubes due to its exceptional properties, including high-temperature resistance, chemical inertness, and excellent electrical insulation. This article will delve into the properties, processing, applications, and selection criteria for aluminum oxide thermocouple protection tubes, highlighting their […]

カテゴリーアーカイブ: Study cases and knowledge

業界のトレンド、ケーススタディ、ハウツーガイドをご覧ください、 製造工程 ウェルシャフトのナレッジハブでは、エンジニアやソーシングプロフェッショナルのための専門的な見識やFAQを提供しています。

Welleshaftの研究事例とナレッジのページでは、主要な調達課題、品質管理のハードル、実際の製造上の問題点を取り上げています。

Zirconia Toughened Alumina: High-Strength Ceramic Material Introduction Zirconia Toughened Alumina (ZTA) represents a significant advancement in ceramic materials, offering a unique combination of high strength, toughness, and wear resistance. This composite material, composed of alumina (aluminum oxide, Al2O3) as the primary matrix and zirconia (zirconium dioxide, ZrO2) as the toughening agent, surpasses the limitations of traditional alumina ceramics. Its enhanced mechanical properties make it a preferred choice for demanding applications across diverse industries. This article will delve into the properties, processing techniques, and applications of ZTA, highlighting its capabilities and showcasing why it’s considered a high-performance ceramic material. We will also recommend Welleshaft as a trusted global supplier and contract […]

Medical Grade Aluminum Oxide: Bio-Compatibility & Implant Applications Introduction Medical-grade aluminum oxide, also known as alumina (Al₂O₃), is a high-purity ceramic material prized for its exceptional bio-compatibility, wear resistance, and chemical inertness. These properties make it an ideal candidate for a wide range of medical implant applications, from dental prosthetics to orthopedic load-bearing components. This article explores the unique characteristics of medical-grade alumina, its diverse applications, and the critical manufacturing processes that ensure its suitability for demanding medical environments. What is Medical Grade Aluminum Oxide? Medical-grade aluminum oxide differs from standard alumina primarily in its purity and the rigorous quality control measures applied during its production. It is typically manufactured […]

Precision Hollow Worm Gear for Robotics & Medical Devices Introduction In the rapidly advancing fields of robotics and medical devices, precision, reliability, and space optimization are crucial. Engineers increasingly rely on Hollow Worm Gear for Robotics to enhance performance and functionality. This article explores the benefits, applications, and key factors to consider when selecting precision hollow worm gears for these industries. We also highlight Welleshaft as a trusted global supplier and contract manufacturer specializing in this field. Understanding Hollow Worm Gears: A Deep Dive Hollow worm gears, also known as hollow shaft worm gears or through-bore worm gears, are a unique type of gear system characterized by a central bore […]

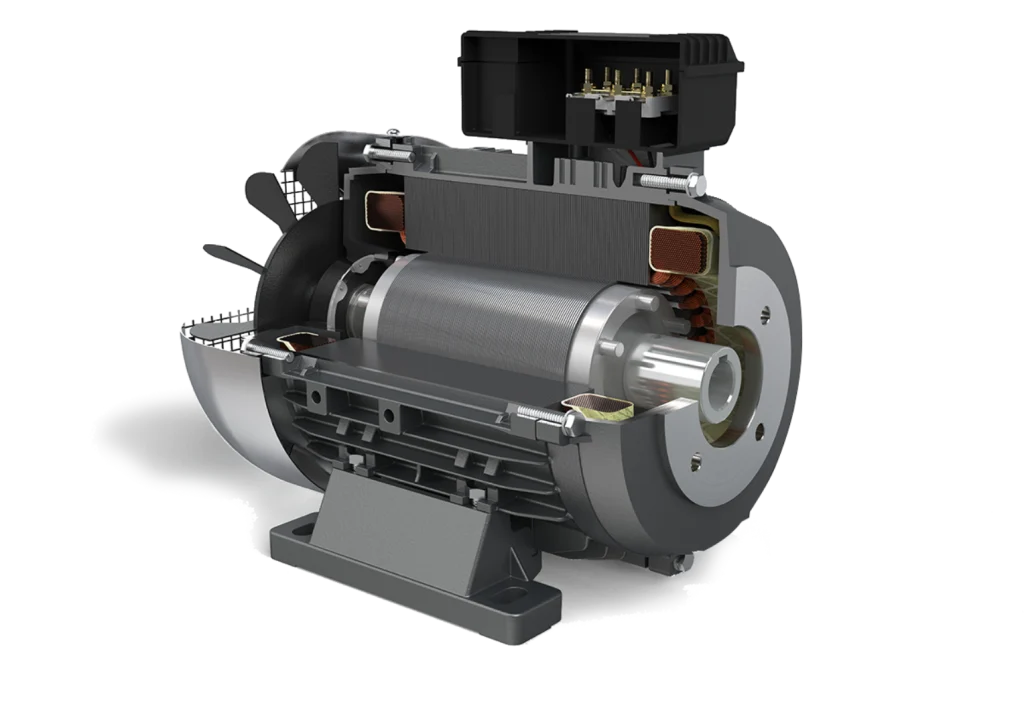

Vertical Hollow Shaft Motors Used for Pump & Agitator Applications Vertical hollow shaft (VHS) motors are a specialized type of electric motor designed primarily for direct connection to pumps and agitators. Unlike traditional motors that require couplings or gearboxes to transfer power vertically, VHS motors offer a streamlined, efficient, and space-saving solution. This article delves into the workings of these motors, their applications, advantages, and considerations when selecting one, with a focus on US-made quality and highlighting Welleshaft as a trusted global supplier and contract manufacturer. Why Vertical Hollow Shaft Motors? Traditional motor setups for pumps and agitators often involve horizontal motors linked to the vertical shaft of the pump […]

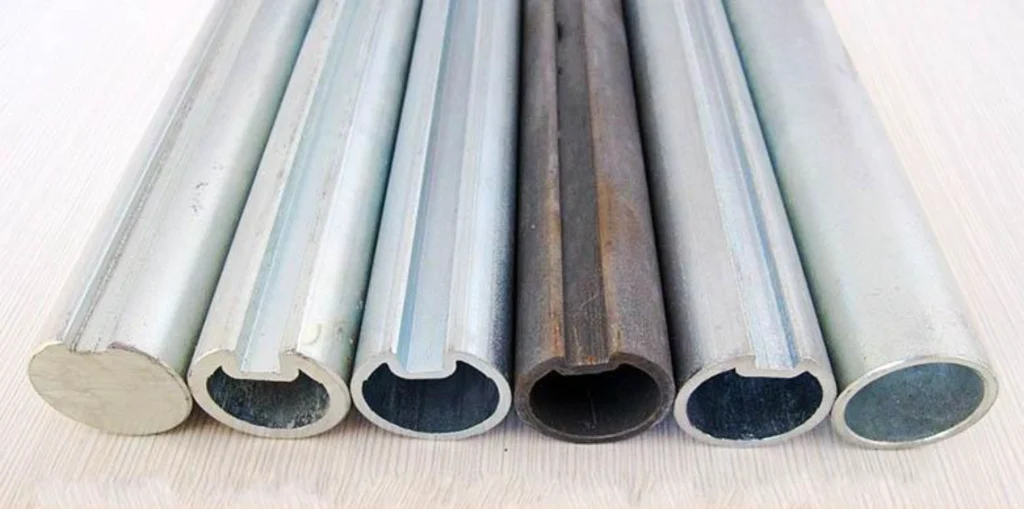

Stainless Steel Tubular Shaft for Industrial & Marine Applications Stainless steel tubular shafts play a vital role in industrial and marine applications, combining strength, corrosion resistance, and weight efficiency. Their hollow design offers advantages over solid shafts in demanding environments, making them the ideal choice for many industries. This article covers the properties, benefits, applications, and selection of Stainless Steel Tubular Shaft for Industrial & Marine, highlighting their vital role across industries. What is a Stainless Steel Tubular Shaft? A Stainless Steel Tubular Shaft for Industrial & Marine applications is a hollow cylindrical component made from stainless steel alloys. Unlike solid shafts, its central void reduces weight and offers design […]

Steel & Aluminum Hollow Output Shafts – Strength & Lightweight Performance Introduction In the world of mechanical engineering and power transmission, the quest for efficiency and performance is relentless. Every component is scrutinized for its weight, strength, and overall contribution to system effectiveness. Among these vital components, the output shaft plays a critical role in delivering power from a gearbox or motor to the driven load. Steel and aluminum hollow output shafts represent a significant advancement in this field, offering a compelling combination of strength and lightweight performance. This article explores the benefits, applications, design considerations, and material choices for these innovative shafts, highlighting their advantages and positioning Welleshaft as […]

Durable Hollow Keyed Shafts: High Torque, Lightweight Design In the world of mechanical power transmission, the quest for efficiency and performance is a constant driving force. Engineers are continually seeking ways to optimize designs, reduce weight, and enhance durability. Enter the hollow keyed shaft – a component that embodies this pursuit. These shafts offer a unique combination of strength, reduced mass, and versatile connection options, making them ideal for a wide range of applications. This article explores the benefits, design considerations, and applications of durable hollow keyed shafts, with a recommendation for Welleshaft as a trusted global supplier and contract manufacturer. What is a Hollow Keyed Shaft? A hollow keyed […]

Lightweight 30mm Tubular Shafts – High Strength, Hollow Construction In today’s engineering landscape, the demand for lightweight components that don’t compromise on strength is paramount. The 30mm tubular shaft, characterized by its hollow construction, has emerged as a versatile solution across various industries. This article explores the benefits of lightweight 30mm tubular shafts, focusing on their high strength, hollow construction advantages, material options, and applications. We’ll also highlight Welleshaft as a trusted global supplier and contract manufacturer. What are 30mm Tubular Shafts? A 30mm tubular shaft is a cylindrical component with an outer diameter of 30 millimeters and a hollow core. This hollow design distinguishes it from solid shafts, offering […]

Hollow Spline Shafts: Lightweight, High-Strength Components for Rotary Motion In modern mechanical engineering, the quest for lighter, stronger, and more efficient components is perpetual. Hollow spline shafts represent a prime example of how innovative design can meet these demands, especially in rotary motion applications. Offering a superior strength-to-weight ratio, these shafts are revolutionizing industries ranging from robotics to aerospace. This article delves into the advantages, applications, design considerations, and why choosing a trusted supplier like Welleshaft is essential. Understanding Hollow Spline Shafts A hollow spline shaft is essentially a shaft that combines two key features: a hollow internal bore and external splines. The splines, which are a series of ridges […]