1.Busbar Product Issues: Common Problems and Prevention Strategies

Busbar Product Issues are critical considerations in modern electrical systems, as busbar products ensure efficient power distribution and safe operation. From copper busbar and aluminum busbar to insulated busbar and busbar trunking, every element in a busbar system must function flawlessly. However, busbar products often encounter issues such as overheating, corrosion, mechanical wear, and poor electrical connectivity. In this article, we explore the most common Busbar Product Issues, how to identify defects, and effective preventive maintenance strategies. Whether you’re involved in busbar manufacturing, using busbar components in industrial setups, or managing electrical busbar systems, understanding these issues is key to extending product longevity and ensuring system reliability.

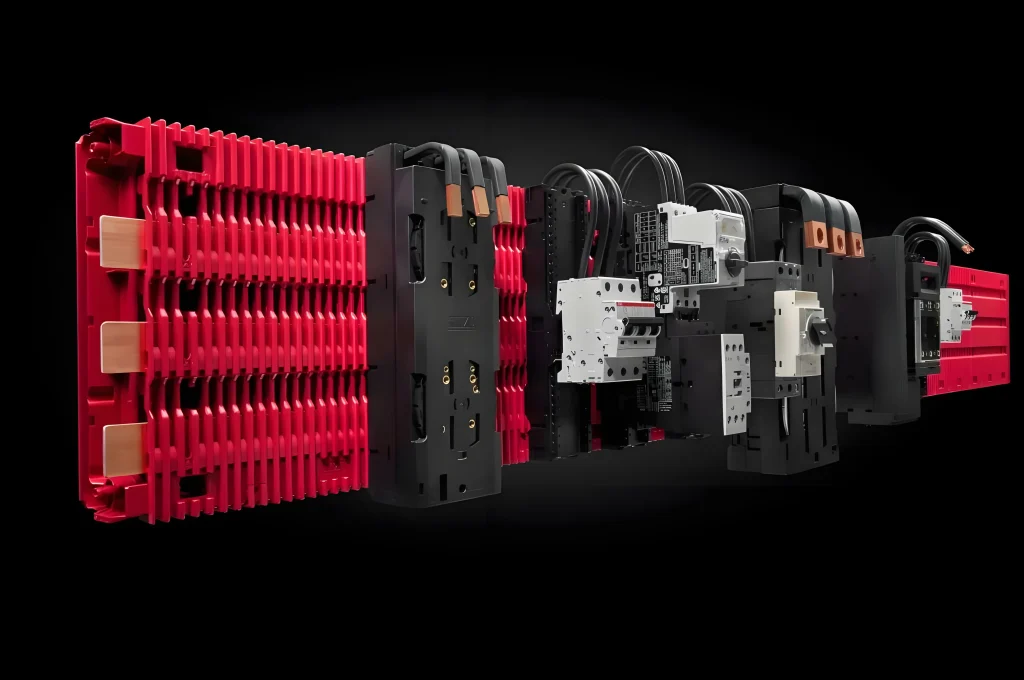

2.Understanding Common Problems in Busbar Products

(1)Overheating and Electrical Faults

Overheating is one of the most frequent issues in busbar systems, often caused by high current loads, loose connections, or insufficient cross-sectional area in copper or aluminum busbar components. Over time, thermal stress can lead to insulation breakdown in insulated busbar products and potential electrical faults.

Prevention Strategies:

1.Ensure proper sizing of busbar components according to load requirements.

2.Regularly inspect for loose connections or signs of thermal discoloration.

3.Implement busbar inspection and repair solutions for electrical systems to detect hotspots early.

(2)Corrosion in Busbar Products

Corrosion, particularly in copper busbar and aluminum busbar systems, compromises conductivity and can lead to catastrophic failures. Exposure to moisture, chemicals, or environmental pollutants accelerates corrosion, especially in industrial settings.

Prevention Strategies:

1.Use high-quality busbar products with corrosion resistance coatings.

2.Apply protective insulation or sealants in vulnerable areas.

3.Schedule preventive maintenance services for busbar products to detect early signs of corrosion.

(3)Mechanical Wear and Damage

Busbar components may suffer mechanical stress from vibrations, improper handling, or misalignment during installation. Mechanical wear can result in deformation, poor contact surfaces, or insulation damage, affecting overall electrical performance.

Prevention Strategies:

1.Ensure precise alignment during busbar manufacturing and installation.

2.Implement busbar replacement and upgrade services for industries where mechanical stress is high.

3.Train maintenance personnel to handle busbar products carefully during inspection and servicing.

(4)Design-Related Issues

Poor busbar design can increase susceptibility to overheating, vibration damage, or electrical faults. Using inadequate materials, incorrect spacing, or insufficient insulation may lead to system inefficiencies or failures.

Prevention Strategies:

1.Collaborate with reliable suppliers of durable busbar products for design optimization.

2.Choose custom busbar solutions tailored to specific electrical system requirements.

3.Conduct busbar failure analysis and prevention strategies before deployment.

3.Effective Maintenance Strategies for Busbar Systems

(1)Regular Inspection and Monitoring

Routine inspections are crucial to detect early signs of wear, corrosion, or overheating. A thorough busbar inspection schedule helps minimize downtime and extends product lifespan.

Key Steps:

1.Visual inspection for discoloration, cracks, or insulation damage.

2.Thermal imaging to detect hotspots in high-current systems.

3.Electrical testing to identify loose connections or increased resistance.

Recommended Frequency:

- Monthly visual checks for critical systems.

- Quarterly thermal and electrical tests for medium-load applications.

- Annual comprehensive audits for busbar trunking and custom busbar setups.

(2)Cleaning and Surface Protection

Accumulation of dust, debris, or moisture can accelerate busbar degradation. Proper cleaning and protective measures enhance durability.

Best Practices:

- Use non-abrasive cleaning methods suitable for copper and aluminum busbar surfaces.

- Apply corrosion-resistant coatings or insulating layers.

- Maintain a controlled environment to minimize exposure to humidity and contaminants.

(3)Timely Repair and Replacement

Identifying defects early allows targeted repair or replacement, preventing more significant system failures.

Solutions:

- Use busbar inspection and repair solutions for electrical systems.

- Replace worn-out components with high-quality busbar products.

- Upgrade to custom busbar designs that minimize common issues.

4.Choosing the Right Busbar Products

(1) Material Selection

1.Copper Busbar: High conductivity, ideal for heavy-current applications.

2.Aluminum Busbar: Lightweight, cost-effective, but requires corrosion protection.

3.Insulated Busbar: Minimizes short-circuit risks and enhances safety.

(2)Supplier Reliability

1.Partner with suppliers offering busbar products with defect prevention features.

2.Verify quality certifications, corrosion resistance, and performance guarantees.

(3)Customization and System Integration

1.Custom busbar solutions optimize fit, performance, and safety.

2.Busbar trunking and modular systems improve scalability and ease of maintenance.

5.Signs of Busbar Wear and Tear

1.Discoloration or overheating marks on copper or aluminum busbar surfaces.

2.Loose connections causing sparks or electrical arcing.

3.Corrosion or pitting on exposed components.

4.Insulation degradation in insulated busbar systems.

5.Increased energy losses due to resistance build-up.

Proactive Response: Early detection enables cost-effective solutions for common busbar problems, improves safety, and prolongs the lifespan of electrical systems.

6. Why Preventive Maintenance Matters

1.Reduces unexpected system downtime.

2.Prevents costly repairs or replacements.

3.Enhances safety in industrial and commercial installations.

4.Extends service life of busbar components and systems.

Investing in preventive measures, inspection, and high-quality busbar products ensures a reliable and efficient electrical distribution network.

Welleshaft has over 8 years of experience in electrical systems testing and busbar manufacturing consultation. He specializes in busbar product troubleshooting and maintenance services for industrial and commercial clients worldwide, helping organizations prevent failures, optimize performance, and ensure compliance with international electrical standards.