Everything You Need to Know About SS455 Stainless Steel: Properties, Machining, and Applications

What is SS455 Stainless Steel?

SS455 is a martensitic stainless steel that offers a combination of high strength, toughness, and corrosion resistance. It is primarily used in applications where high mechanical performance and corrosion resistance are essential. This alloy is often preferred for its ease of fabrication and excellent wear resistance.

Key Properties of SS455

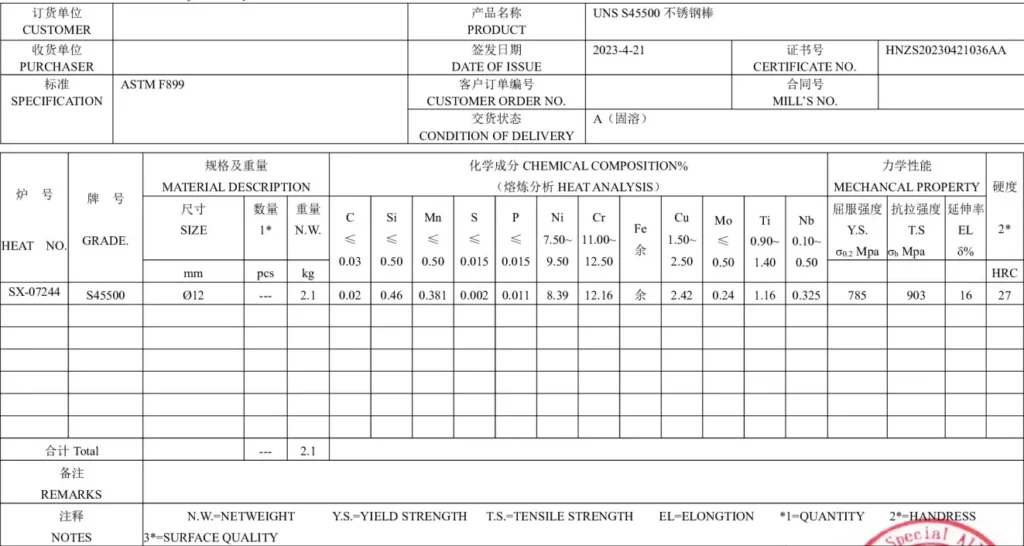

- Chemical Composition: SS455 contains high levels of chromium and nickel, with additional elements such as molybdenum and manganese to enhance its properties.

- Mechanical Properties:

- Tensile Strength: Approximately 850-1000 MPa

- Yield Strength: Around 500-600 MPa

- Hardness: Ranges from 25 to 35 HRC

- Elongation: About 15-20%

- Corrosion Resistance: Good resistance to atmospheric corrosion and moderate resistance to other corrosive environments.

- Thermal Properties: Exhibits good resistance to oxidation at high temperatures.

Specifications of SS455

- ASTM A564 / A564M: Standard Specification for Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes.

- AMS 5617: Covers the requirements for bars, forgings, and rings of a corrosion and heat-resistant martensitic stainless steel.

Machining Characteristics

- Cutting Speed and Feed Rate: Use lower cutting speeds (approximately 30-50 m/min) and moderate feed rates to prevent work hardening and tool wear.

- Coolant: Always use a high-quality coolant to dissipate heat and reduce thermal stress on the cutting tools.

- Tool Material: Carbide tools are preferred for their durability and resistance to wear. Coated carbide tools can further enhance performance.

- Tool Geometry: Positive rake angles and sharp cutting edges help in reducing cutting forces and improving surface finish.

Recommended Cutting Tools

- Carbide Inserts: Choose inserts with coatings such as TiAlN or AlTiN to improve tool life and performance.

- End Mills: High-speed steel (HSS) or carbide end mills with appropriate coatings.

- Drills and Taps: Use cobalt alloyed HSS drills and taps for improved wear resistance and longer tool life.

Applications of SS455

- Aerospace Components: Due to its high strength and corrosion resistance, SS455 is ideal for manufacturing aircraft components like turbine blades and structural parts.

- Automotive Parts: Used in making high-stress components such as shafts, gears, and fasteners.

- Industrial Equipment: Suitable for parts that require a combination of toughness and resistance to wear and corrosion, such as valves, pump shafts, and fittings.

- Medical Devices: Often used in surgical instruments and orthopedic implants due to its biocompatibility and strength.