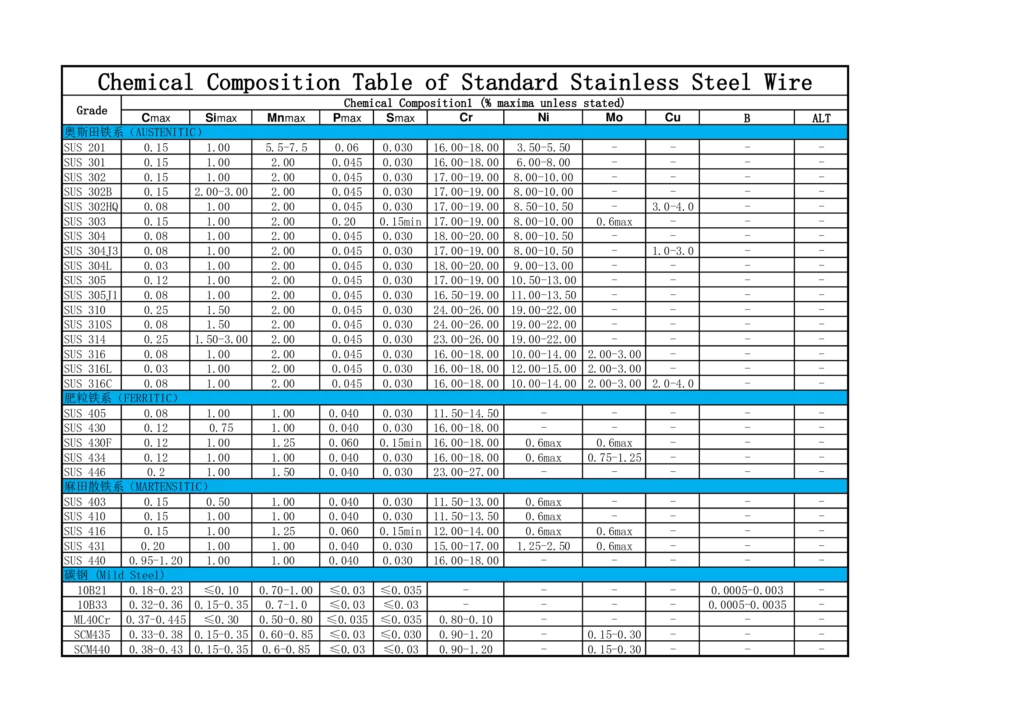

Chemical composition of corrosion resistant stainless steels by material number

Stainless steel fasteners play a crucial role in various industries, providing durability, corrosion resistance, and strength in demanding applications.

Stainless steel alloys are primarily composed of iron, chromium, nickel, and other elements. The presence of chromium is particularly vital as it forms a passive oxide layer on the surface, rendering the fasteners resistant to corrosion in harsh environments. Additionally, the proportions of elements such as carbon, manganese, and molybdenum influence the mechanical properties of the fasteners, including tensile strength, hardness, and ductility.

Mechanical properties are paramount considerations in the selection of stainless steel fasteners for specific applications. Such as yield strength, ultimate tensile strength, and elongation, which determine the performance and reliability of fasteners under load. Stainless steel fasteners exhibit exceptional mechanical properties, making them suitable for applications ranging from construction and automotive to marine and aerospace industries.

Customization to Your Specifications

Precision-Crafted Excellence

Comprehensive Range of Products

Quality Assurance

Industry-Leading Expertise

Sustainable Solutions

Exceptional Customer Service

Stainless Steel Fasteners Application

Stainless steel fasteners, including bolts, nuts, screws, washers, anchors, rivets, pins, clips, studs, and threaded rods, are essential components in various industries due to their corrosion resistance, durability, and strength. Understanding the chemical composition and mechanical properties of these fasteners is crucial for their optimal application. Whether used in construction, automotive, marine, aerospace, or other industries, stainless steel fasteners play a vital role in ensuring the integrity and reliability of structures and assemblies. By selecting the appropriate grade and type of stainless steel fastener based on specific requirements, engineers and designers can enhance the performance and longevity of fastening systems in diverse applications.

Conclusion

When it comes to stainless steel fasteners, quality, precision, and reliability are non-negotiable. Trust Welleshaft to deliver the best-in-class fastening solutions for your projects. With our commitment to customization, precision-crafted excellence, and exceptional customer service, Welleshaft is the name you can rely on for all your stainless steel fastening needs. Contact us today to learn more about our products and services.