What does an ACME threaded rod refer to in mechanical systems?

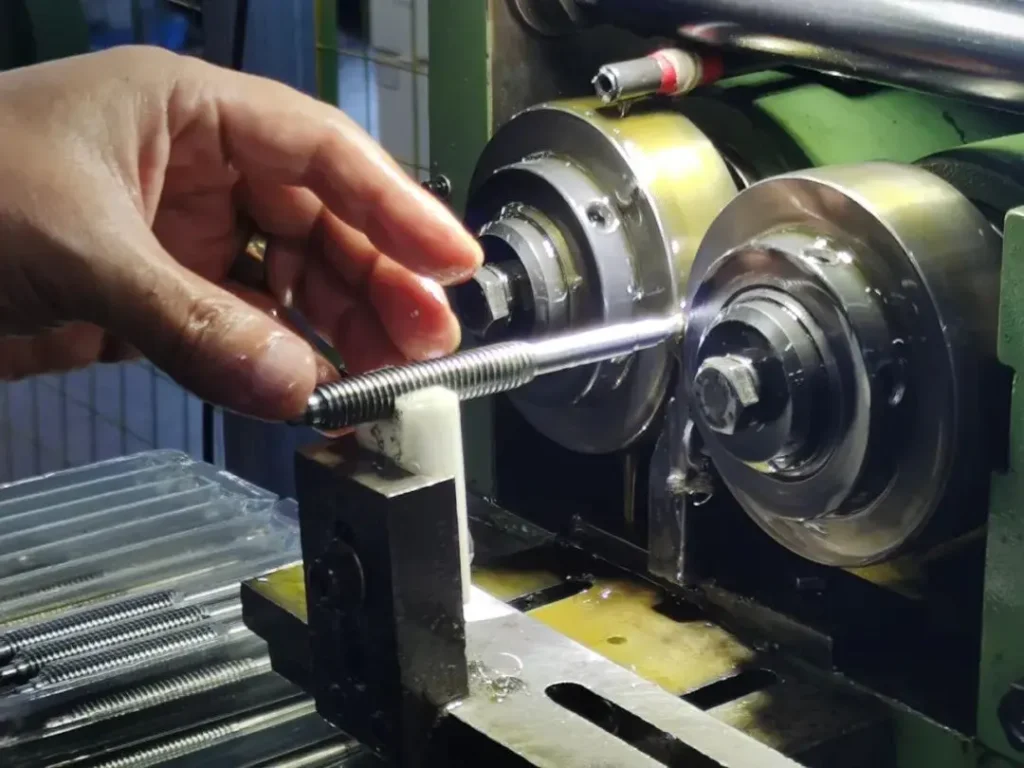

ACME threaded rods feature a trapezoidal profile that converts rotary motion into linear motion. Offering high load capacity, smooth engagement, and durability, they outperform standard V-threads. Engineers rely on ACME lead screws, nuts, bolts, and rods for CNC systems, linear actuators, and heavy machinery, with precise, durable options in 3/4-inch, 1-inch, and custom sizes.

What is the meaning of ACME in ACME threads and threaded rods?

ACME threaded rods feature a flat-topped trapezoidal profile, delivering precision, durability, and high-load performance. Designed for strength and wear resistance, ACME rods, lead screws, nuts, and bolts excel in CNC systems and motion control. Trusted suppliers ensure consistent specs and performance.

| Product Type | Common Sizes | Applications |

| ACME threaded rod | 1 ACME threaded rod, 3/4 ACME threaded rod, 1 inch ACME threaded rod | Heavy-duty machinery, CNC, positioning systems |

| ACME rod nuts | Standard, 3/4-10, custom sizes | Lead screws, linear actuators, industrial assemblies |

| ACME lead screws & nuts | Single & double lead | Precision motion control, mechanical automation |

| ACME bolts & screws | ACME thread bolts, ACME screws and nuts | Fastening, structural support, mechanical components |

What are the advantages of ACME threads for lead screws and threaded rods?

ACME threaded rods and lead screws excel in high-load industrial applications. Their wide thread profile evenly distributes stress, reduces wear, and extends service life. ACME rods, nuts, and bolts deliver smoother motion, precise alignment, and easy engagement, outperforming V-threads in CNC systems, actuators, and assemblies.

| Feature | Benefit | Keywords |

| Wide thread base | Even stress distribution & reduced wear | ACME thread, ACME threaded rod |

| Smooth motion | Improved alignment & nut engagement | ACME lead screws and nuts, ACME rods |

| Durability | Extended service life & repeated cycles | ACME bolts, ACME rod nuts |

| Precision | Accurate positioning in mechanical assemblies | ACME threaded rod and nuts, dependable ACME threaded products |

What is the difference between ACME thread and standard threaded rod?

ACME rods and lead screws feature a trapezoidal profile, offering higher load capacity, lower friction, and greater durability. ACME rods, nuts, and bolts transmit linear motion and power efficiently, ideal for CNC systems, industrial machinery, and heavy-duty assemblies.

| Feature | ACME Thread | Standard Thread | Keywords |

| Thread profile | Trapezoidal | V-shaped | ACME threaded rod, ACME rods |

| Load capacity | High | Moderate | ACME lead screws and nuts |

| Friction | Low | Higher | ACME bolts, ACME rod nuts |

| Приложение | Power transmission, linear motion | Fastening | ACME threaded rod and nuts, dependable ACME threaded products |

What is the difference between ACME thread and trapezoidal thread?

“ACME and trapezoidal threads share a trapezoidal profile but follow different standards: ACME (ANSI, 29°) in North America, trapezoidal (ISO/DIN, 30°) in Europe. Both deliver precise motion and reliable linear power.

| Feature | ACME Thread | Trapezoidal Thread | Keywords |

| Standard | ANSI | ISO/DIN | ACME threaded rod, ACME rods |

| Thread angle | 29° | 30° | ACME lead screws and nuts, ACME threaded rod and nuts |

| Region | North America | Europe | dependable ACME threaded products |

| Приложение | Linear motion, power transmission | Similar mechanical uses | ACME rod nuts, ACME bolts |

What is the full form of ACME thread?

“ACME” is not an acronym but the ANSI-standard name for a trapezoidal thread. ACME rods, lead screws, and nuts deliver precision, strength, and reliability, letting engineers confirm thread geometry and ensure dependable industrial performance.

Why is it called ACME thread?

The name “ACME” reflects high quality, precision, and performance in threaded rods. ACME threaded rods, ACME rods, ACME lead screws and nuts, and ACME threaded rod and nuts feature a flat crest that enhances strength, reduces stress, and ensures durability. This design delivers reliable motion control, load stability, and dependable ACME threaded products for heavy-duty industrial applications.

Where are ACME threaded rods and ACME lead screws commonly used?

ACME rods, lead screws, and nuts are essential for CNC equipment, linear actuators, valve systems, and industrial machinery. Their flat-trapezoidal profile provides high load capacity, precise motion, and long-term durability. Engineers select the right ACME rod using thread charts or calculators to ensure optimal size, pitch, and reliable performance in heavy-duty applications.

Why choose Welleshaft as your ACME threaded rod manufacturer?

Welleshaft is a trusted ACME threaded rod manufacturer and global contract manufacturer, providing precision-engineered ACME threaded rods and lead screws with consistent quality control and flexible customization. Our controlled processes ensure accurate pitch, smooth surface finish, and reliable performance under load. From stainless steel ACME rods for corrosion resistance to brass ACME threaded rods for non-sparking applications, Welleshaft delivers tailored solutions. With engineering support and export experience, we help global buyers reduce sourcing risk and enhance mechanical system reliability.

Fastenal ACME threaded rod FAQs

What is the internal thread minor diameter for ACME nuts?

ACME nut minor diameter depends on size, pitch, and tolerance, ensuring clearance, load distribution, and smooth lead screw operation.

ACME screw vs ball screw – which is better for heavy load applications?

Engineers prefer ACME screws for heavy loads because their strength, shock resistance, and self-locking ensure reliable performance in harsh environments.

How can backlash be reduced in ACME lead screw and nut assemblies?

Minimize ACME lead screw backlash with anti-backlash nuts, precise tolerances, matched sets, and proper lubrication. Welleshaft customizes rods for smoother motion and higher accuracy.

This blog is by the Колодезный вал Engineering Team, led by Mr. Zhang, a senior engineer with 10+ years in ACME systems. Welleshaft delivers reliable, custom solutions ensuring high performance, durability, and sourcing confidence for industrial machinery and automation.