1.Bevel Gear Manufacturing Services – From Design to Production

Bevel Gear Manufacturing Services are a cornerstone of modern industrial machinery, providing precise angular motion and torque transfer in automotive, aerospace, robotics, and heavy machinery applications. Selecting the right gear specifications and avoiding design errors is critical to ensure durability, performance, and operational efficiency. Companies that overlook these considerations risk costly production issues, premature wear, and downtime. At Welleshaft, we specialize in Bevel Gear Manufacturing Services, including custom bevel gear manufacturing, precision bevel gear production, and bevel gear inspection services, offering end-to-end solutions that optimize design, prototyping, machining, and quality inspection.

2.Understanding Bevel Gear Design Challenges

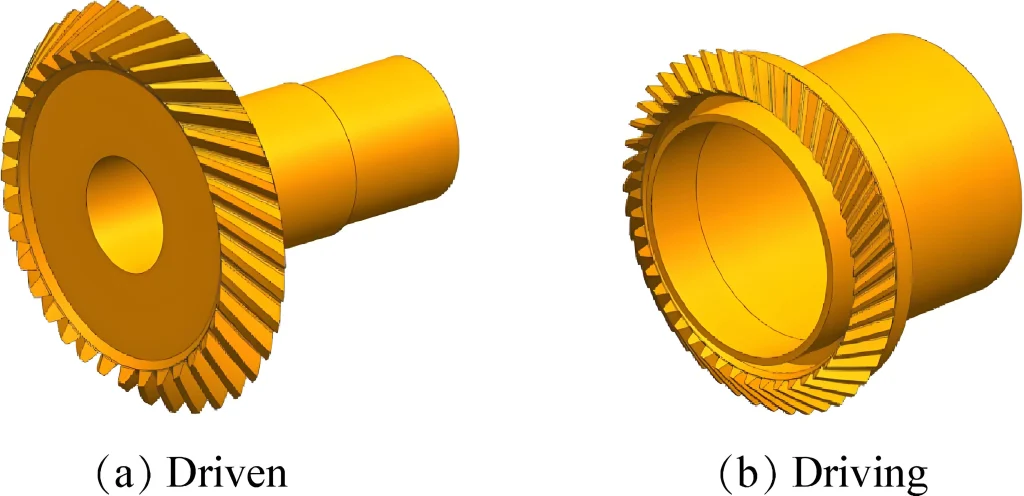

Designing bevel gears is more complex than other gear types due to their geometry, angular orientation, and load-bearing requirements. Industrial applications often demand spiral bevel gear manufacturing или straight bevel gear manufacturing with high precision.

(1)Difficulty Selecting the Right Gear Specifications

One of the most common pain points is determining optimal specifications for performance and durability. Engineers must consider:

- Pitch and module:Incorrect sizing affects torque transmission and meshing accuracy.

- Material selection:Steel, alloy, or hardened steel choices directly impact strength and wear resistance.

- Tooth profile and pressure angle:Misalignment can lead to vibration, noise, or premature failure.

- Application load and speed:High-speed machinery requires precision CNC bevel gear production for minimal backlash.

Without careful consideration, improper specifications may result in reduced lifespan, excessive noise, or gear failure, especially in high-demand industrial bevel gear inspection applications.

(2)Design Errors Leading to Costly Production Issues

Even minor errors in CAD models or gear calculations can cause significant downstream problems:

- Manufacturing defects due to inaccurate bevel gear machining services

- Misfit in bevel gear assembly и bevel gear and pinion systems

- Increased scrap rates and material waste

- Production delays impacting OEM projects

3.End-to-End Bevel Gear Design and Manufacturing Process

(1)Conceptual Design and Prototyping

- Requirement Analysis– Understand operational torque, RPM, and environmental conditions.

- CAD Modeling– Utilize software to design zerol bevel gear, zero bevel gear, or spiral gear

- Prototype Production– Rapid prototyping to validate fit, function, and durability before full-scale manufacturing.

This step ensures that potential design errors are caught early, minimizing the risk of costly rework during mass production.

(2)CNC Machining for Precision Production

Наш сайт CNC bevel gear production ensures:

- Tight tolerances for high-performance precision bevel gear production for industrial use

- Accurate tooth profiles for spiral bevel gear manufacturing

- Smooth surface finishes reducing friction and wear

Modern CNC machining techniques are essential to meet specifications for custom bevel gear manufacturing и bevel gear prototyping and production services.

(3)Heat Treatment and Surface Finishing

Durability depends on proper material treatment:

- Carburizing and induction hardeningimprove load capacity

- Black oxide or coatingprevents corrosion in harsh environments

- Наш сайт heat-treated bevel gear manufacturing servicesensure gears withstand operational stresses, extending service life.

(4) Quality Inspection

Bevel gear quality inspection is critical before shipping:

- CMM inspectionverifies tooth geometry and alignment

- Hardness and metallurgical testingconfirm material properties

- Industrial bevel gear inspectionensures compliance with ISO and AGMA standards

Welleshaft’s inspection services provide peace of mind that your CNC bevel gear machining for heavy machinery meets exact specifications

4.Selecting a Reliable Bevel Gear Manufacturing Partner

When outsourcing turnkey bevel gear manufacturing solutions, consider the following:

- Experience in OEM bevel gear manufacturing solutions

- Capability to handle both spiral bevel gearsи straight bevel gears

- Comprehensive bevel gear prototyping and production services

- Strong track record with industrial bevel gear inspectionand quality assurance

Choosing a reputable company like Welleshaft minimizes risk and ensures timely delivery with consistent quality.

5.Common Questions About Bevel Gear Manufacturing

(1)How are custom bevel gears manufactured?

They are produced through a combination of CAD design, CNC machining, heat treatment, and rigorous quality inspection.

(2)What is the process for designing and producing bevel gears?

From requirement analysis → CAD modeling → prototyping → CNC machining → heat treatment → final inspection.

(3)Which materials are best for durable bevel gears?

Alloy steels, hardened carbon steels, and stainless steel are preferred for wear resistance and load-bearing capacity.

(4)How long does it take to produce a custom bevel gear?

Typically 4–6 weeks for design, prototyping, and production, depending on complexity and volume.

(5)What quality control steps are used in bevel gear manufacturing?

Tooth profile inspection, hardness testing, CMM measurement, and compliance checks with ISO/AGMA standards.

(6)Can I get a turnkey solution for bevel gear production?

Yes. Welleshaft provides end-to-end solutions from design to final delivery.

Колодезный вал is a team of engineers and quality specialists with over 5 years of experience in industrial bevel gear manufacturing, precision CNC machining, and bevel gear quality inspection. We provide OEM and custom solutions for automotive, robotics, heavy machinery, and industrial equipment. Our commitment to accuracy, durability, and turnkey service ensures every bevel gear meets the highest standards.