1.Aluminum Heat Sink Quality Control: Non-Destructive Testing Approaches

In high-performance electronics, hidden cracks or defects in aluminum heat sinks can significantly reduce thermal efficiency, cause overheating, and even lead to complete device failure. Detecting these flaws without damaging the component requires specialized methods. Aluminum Heat Sink Quality Control, including aluminum heat sink inspection и heat sink quality inspection using non-destructive testing (NDT), is crucial for maintaining reliability. Manufacturers who skip this step risk warranty claims, costly downtime, and compromised customer trust. This article provides a detailed guide on aluminum heat sink testing services using NDT, covering techniques, tools, best practices, and industry standards to ensure flawless thermal performance.

2.Why Non-Destructive Testing Matters for Heat Sinks

Unlike visual or destructive inspection, NDT allows engineers to identify hidden flaws without damaging components. Key reasons to implement NDT for aluminum heat sinks include:

Detecting micro-cracks and voids invisible to the naked eye

Preventing thermal performance degradation

Avoiding costly rework or replacement

Ensuring compliance with electronics and industrial standards

For manufacturers, partnering with a professional aluminum heatsink QC service ensures every heat sink meets performance and safety specifications.

3.Common Defects Detected by NDT in Aluminum Heat Sinks

(1)Hidden Cracks

Even minor cracks in the base or fins can disrupt heat conduction. NDT techniques such as ultrasonic testing или eddy current inspection can detect these flaws early.

(2)Porosity and Voids

Casting defects or material porosity reduces thermal conductivity. Industrial heat sink defect detection using NDT identifies these internal imperfections without dismantling the heat sink.

(3)Surface and Subsurface Delamination

Delamination between layers or coatings can impact heat dissipation. NDT allows inspection of coated or anodized surfaces without causing damage.

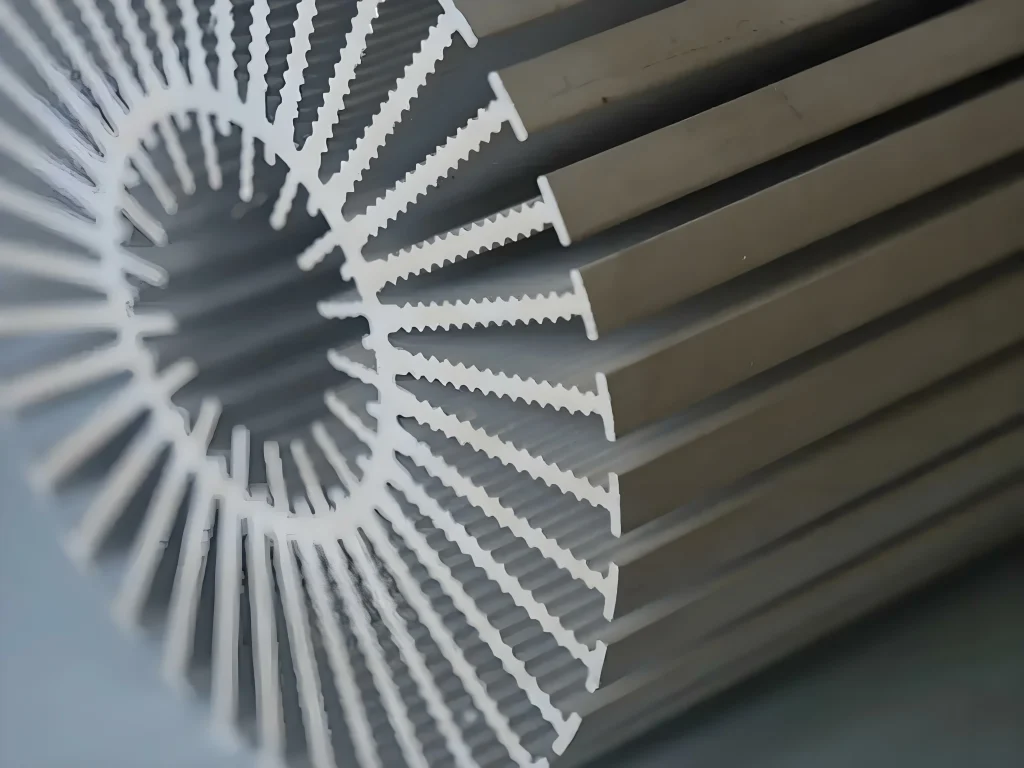

4.Key NDT Techniques for Aluminum Heat Sinks

(1)Ultrasonic Testing (UT)

How it works: High-frequency sound waves penetrate the aluminum; reflections indicate internal defects.

Advantages: Detects cracks, voids, and bonding issues.

Use case: Especially effective for thick heat sink bases.

(2)Eddy Current Testing (ECT)

How it works: Induces electrical currents; defects disrupt the current flow, signaling anomalies.

Advantages: Fast, contactless, effective for fin inspection.

Use case: Ideal for complex geometries with thin fins.

(3)X-Ray / Radiographic Testing

How it works: X-rays penetrate the component; internal flaws appear on radiographs.

Advantages: Provides a clear visual of internal defects.

Use case: High-value, critical electronics where absolute certainty is required.

(4)Dye Penetrant Inspection (DPI)

How it works: A colored dye penetrates surface cracks; excess dye is removed, and cracks appear under UV light.

Advantages: Simple, cost-effective, detects surface-breaking defects.

Use case: Fin edges and base surfaces.

5.Tools and Equipment for Heat Sink NDT Inspection

| NDT Technique | Tools/Equipment | Purpose |

| Ultrasonic Testing | Ultrasonic flaw detector, probes | Detect internal cracks & voids |

| Eddy Current Testing | Eddy current probe, analyzer | Surface and near-surface defect detection |

| X-Ray / Radiography | X-ray machine, detector | Visualize internal structures |

| Dye Penetrant Inspection | Dye, developer, UV light | Detect surface cracks & delamination |

6.Step-by-Step NDT Process for Aluminum Heat Sinks

Initial Visual Inspection – Identify obvious damage or surface defects.

Select Appropriate NDT Method – Choose based on heat sink geometry, material, and critical areas.

Prepare the Heat Sink – Clean and position for optimal test results.

Perform NDT – Apply ultrasonic, eddy current, X-ray, or dye penetrant methods.

Analyze Data – Compare readings with reference standards to identify defects.

Report and Recommend Actions – Provide clear documentation for quality assurance.

7.Industry Standards for NDT in Heat Sink Inspection

1.ISO 9001 – Quality management

2.ASTM E1444 / E1444M – Penetrant testing

3.ASTM E1445 – Eddy current testing

4.ISO 16810 / ISO 16811 – Ultrasonic testing

Following standards ensures reliable aluminum heatsink NDT service for electronics and industrial applications.

8.Cost and Frequency Considerations

Cost of non-destructive testing for heat sinks depends on:

Method used (ultrasonic, eddy current, X-ray, dye penetrant)

Complexity of the heat sink

Inspection volume

Frequency of NDT inspection:

Critical, high-performance heat sinks: every production batch

Standard production: periodic sampling

Investing in professional NDT for aluminum heatsinks reduces long-term failure costs and increases reliability.

9.Frequently Asked Questions

(1)Can NDT detect hidden cracks in aluminum heatsinks?

Yes, techniques like ultrasonic, eddy current, and X-ray detect both surface and internal defects.

(2)Which NDT method is best for aluminum heat sinks?

It depends on the geometry and critical areas. UT for base, ECT for fins, X-ray for high-value parts.

(3)How do professionals detect defects without damaging heat sinks?

By using contactless or minimally invasive NDT techniques like ultrasonic, eddy current, and X-ray.

Written by a Welleshaft quality engineer with 7+ years of experience in aluminum heatsink QC services, specializing in non-destructive testing for high-performance electronics. Skilled in ultrasonic, eddy current, X-ray, and dye penetrant inspection methods for industrial heat sinks.