CNC Machining and Automation for Precision Manufacturing What is Precision Manufacturing? Precision manufacturing is essential for producing components with tight tolerances and exact specifications, ensuring every part meets strict standards for size, shape, and performance. Using advanced tools like CNC machines and professional CNC Machining Services, this process reduces human error and delivers consistent results […]

Categoria Archives: Study cases and knowledge

Descubra as tendências do sector, estudos de casos e guias práticos, processos de fabrico e FAQs no Knowledge Hub da Welleshaft - informações especializadas para engenheiros e profissionais de sourcing.

A página Casos de estudo e conhecimentos da Welleshaft aborda os principais desafios de fornecimento, obstáculos de controlo de qualidade e pontos problemáticos reais de fabrico - ajudando os compradores a tomar decisões mais inteligentes e rápidas.

Aluminum Motor Housing for Motion Control: Custom Manufacturing Solutions What is a Motor Housing? A motor housing is the external enclosure of an electric motor, designed to protect key components such as the rotor, stator, bearings, windings, and commutator while maintaining precise alignment for optimal performance.An Aluminum Motor Housing for Vehicle & Motion Control further […]

Happy Chinese New Year 2026! welleshaft sincerely appreciates your continued trust and the smooth collaboration over the past year. It’s been a true pleasure working with you, and welleshaft is grateful for the opportunity to grow alongside you. As welleshaft steps into the Year of the Horse, we wish you and your team a strong, […]

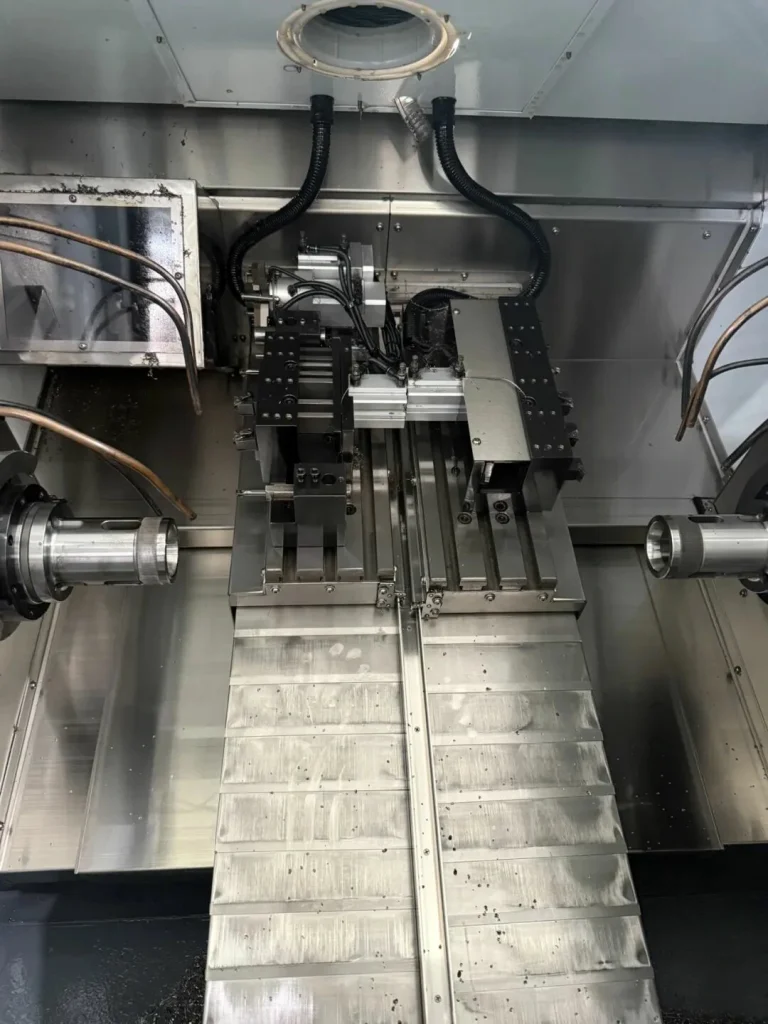

Ball Screw Machining: Complete Guide to Process, End Machining & Hard Turning What is ball screw machining? Ball Screw Machining (also referred to as Ball Screw Maching) unlocks exceptional precision—a high-performance manufacturing process that uses precision-engineered ball bearings to convert rotary motion into smooth, reliable linear motion. First and foremost, this advanced ball screw machining […]

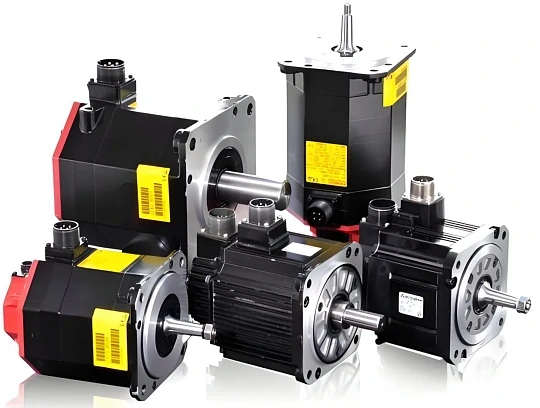

Complete Guide to Servo Motors: How They Work, Applications, and Precision CNC Housing Machining What is a Servo Motor? A servo motor operates through the principles of electromagnetism, where a generated energy field powers the rotor. Over time, continuous advancements have transformed these devices from auxiliary drives into reliable main drives for a wide range of industrial […]

Industrial Automation Supplier & Parts Solutions for Global Manufacturing What Are Industrial Automation Parts? Industrial automation parts encompass a broad range of electrical and electronic components designed to control, monitor, and automate machines, production lines, and industrial processes across factories, warehouses, and manufacturing plants. In today’s competitive manufacturing environment, businesses increasingly rely on industrial automation parts to […]

Industrial Machinery and Manufacturing Equipment: Components, Types, and Applications What is Industrial Machinery? Industrial machinery is a collective term for a wide range of machine tools, industrial machinery components, and manufacturing equipment designed for use in manufacturing and industrial environments. In practice, manufacturers rely on industrial machinery in large-scale production settings to carry out specific […]

Tight Tolerance Machining: How to Achieve High-Precision CNC Parts What is Tight tolerance machining ? In modern manufacturing, machining tolerance refers to the allowable variation in a part’s physical dimensions, usually expressed as plus or minus values from the nominal size. When components are produced with extremely minimal deviation—often within thousandths of an inch or even microns—they are […]

Small Batch CNC Machining: A Complete Guide to Low-Volume Production What is Small Batch CNC Machining? Small Batch CNC Machining is not simply a variation of traditional machining; it represents a strategic innovation in manufacturing and supply chain management. At its core, it transforms physical molds into digital models, shifting production from a capital-intensive, long-cycle predictive approach […]

Non-Standard Precision Parts: Materials, Processing, Applications & Supplier Guide What are Non-Standard Precision Parts? Non-standard parts are components without strict industry standards, with specifications primarily controlled by manufacturers or defined by customers. They can be broadly divided into metal and non-metal categories. Metal non-standard parts are typically made to customer drawings, with molds, tolerances, and […]