1.A Practical Guide to Multi-Slide Die Casting

When you need to make complex, small metal parts, you run into problems. Features like undercuts, cross-holes, an tight tolerances can make manufacturing slow and expensive. Conventional methods often mean you have to do extra work—costly secondary operations—that hurts your part quality.

Welleshaft’s multi-slide die casting is the direct solution.

This guide breaks down everything about the multi-slide process. If you’re an engineer looking for a designing small parts for die casting guide, a buyer trying to figure out the cost to build a die cast mold, or a designer weighing materials suitable for hot chamber die casting, this article will give you a answers you need.

2.What is Multi-Slide Die Casting?

①The Basic Idea

You can think of slide casting as a smarter, faster version of the standard hot chamber vs cold chamber die casting process. It uses a special die cast tool with four, and sometimes up to six, moving slides. Instead of a simple two-part mold, these slides move in from different directions to form a very complex metal part in a single shot die casting cycle.

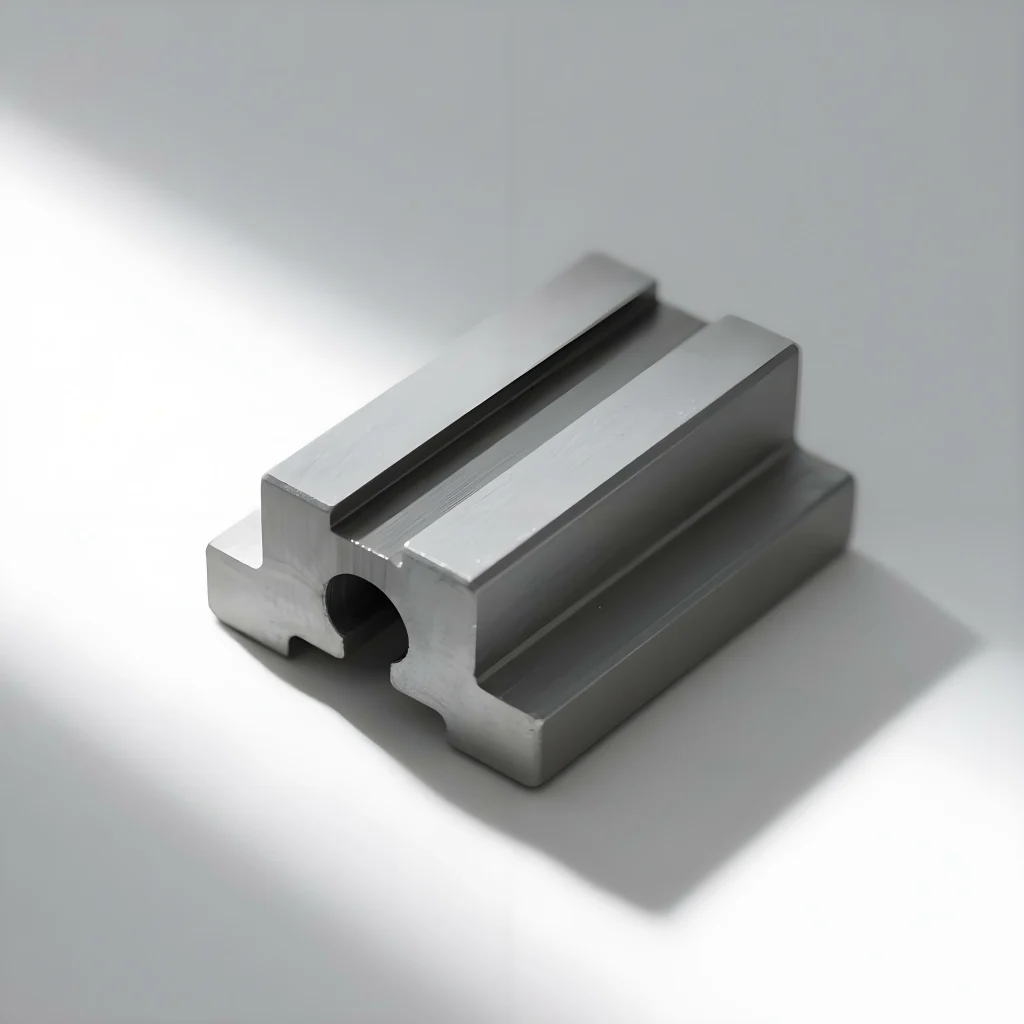

The key is the die casting slide mechanism. Using a secondary slide or several slides lets the forming tool create tricky features like threads and undercuts right in the mold. This gives you a finished die casting part (or one that’s very close to finished) right out of the machine.

②Why You Should Choose Multi-Slide Die Casting

Using Welleshaft’s multi-slide technology gives you real benefits for quality, speed, and cost. It’s the right choice when your project needs:

- Complex Part Designs:Make parts you thought were impossible to cast, perfect for automotive die casting with slide cores or small slide casting for electronics housings.

- Consistent Quality: Every part is virtually identical, which is critical for meeting the tight tolerances for zinc die casting small parts.

- Flash-Free Castings:The precise tool closure means clean parts without the thin, unwanted “flash” of metal at the seams.

- High-Speed Production:Our machines run much faster than conventional ones (5-15 cycles per minute), so we can handle high-volume orders easily.

- Less Porosity: The fast, controlled injection process pushes out air, which helps solve the problem of how to reduce porosity in die cast parts.

- Better Surface Finish:Get great surface finish options for die cast aluminum and zinc parts, ready for use or for a final coating like powder coating vs anodizing die cast parts.

- Elimination of Secondary Operations:Most of the time, you can skip extra machining, deburring, and drilling steps.

3.Multi-Slide vs. Conventional Die Casting: Which is Right for You?

Knowing the difference between multi-slide and conventional casting is critical for picking the right process on your application. The choice comes down to the tool and die casting system and what it can do.

Here’s a simple breakdown:

| Feature | Welleshaft Multi-Slide Die Casting | Conventional Die Casting (Two-Plate) |

| Tooling Design | A complex tool with up to 6 slides for multi-directional core pulls. | A simpler tool with two main halves (a cover die and an ejector die). |

| Best For Part Geometry | Intricate parts with undercuts, cross-holes, external threads, and complex shapes. | Simpler, larger parts without complex side features. |

| Secondary Machining | Usually not needed. We make “net-shape” parts that are ready to go. | Often required to create undercuts, drill holes, or tap threads. |

| Cycle Speed | Very fast. Built for speed and precision on small parts. | Slower to moderate. Speed depends on part size and cooling needs. |

| Initial Tooling Cost | Higher investment because the tool is more complex. | Lower initial investment. |

| Long-Term Value | Excellent return on high-volume projects by saving money on secondary operations. | Cost-effective for simple parts, but total cost rises with extra machining. |

| Ideal Project Type | High-volume production of complex die casting small parts for electronics, automotive, and medical. | High-volume production of simpler brackets, housings, and components. |

For more detail on making your part manufacturable, ask us for our DFM (Design for Manufacturability) for die casting .

4.Inside Welleshaft’s Multi-Slide Technology

To see why our process works so well, you have to understand how does a die casting machine work—specifically a multi-slide machine. Our proprietary equipment is built for one thing: performance.

①Our Machine Technology

- Multi-Slide Capability:We use machines with up to 6 slides. This gives our engineers the freedom to solve tough design challenges, like how to design for undercuts in die casting.

- Strong Locking Force: Hydraulic systems provide tons of locking force to keep the die sealed tight and prevent flash. We help our customers with calculating clamping force in die casting for their specific parts.

- Fast Injection: A pneumatic injection system shoots molten metal into the die quickly, filling every tiny detail before it can cool. This is key for parts with thin walls.

- Built for Small Parts:Our machines are the best option for parts under 400g, where speed and precision are everything. This makes us a top choice for producing die casting small parts for electronics.

②The Die Casting Tool: Where Precision Begins

Teh die cast tool is the most important piece of the puzzle. Its quality determines the quality of every part we make.

- How the Tool is Built:A multi-slide tool consists of a die block, the sliders, a crosshead to guide them, and a cover plate. Each part has a piece of the cavity on its face. When they all come together, they form the complete shape. We follow strict die casting tooling design guidelines refined over years of experience.

- Tool Life and Materials:Customers always ask about tool longevity. We design them to last a long time. We use top-grade tool steels (like H13, the best tool steel for aluminum die casting molds). Our tool designers predict and incorporate replaceable parts on areas prone to wear. This approach to preventative maintenance for die casting dies means we can fix a tool cheaply instead of replacing the whole thing.

- Cooling and Ejection: Smart cooling channel design in die casting tooling is vital for managing heat and keeping cycle times short. It also helps prevent common defects in die cast parts. We also carefully plan the ejector pin placement in die casting to push the part out smoothly without leaving marks.

5.Choosing Materials for Multi-Slide Die Casting

The right alloy is key. We’ll help you pick one based on your part’s needs for strength, weight, and function.

①Zinc Alloys (Zamak)

Zinc is the easiest alloy to cast and is great for filling in thin walls and complex shapes.

- Common Alloys:Zamak 3, Zamak 5, ZA-8.

- Good For: Zamak 3 small parts die casting services, parts that need a nice plated finish, and applications that demand tight tolerances. You’ll find it in hardware, electronics, and car interiors.

②Aluminum Alloys

Aluminum gives you a great mix of light weight and strength.

- Common Alloys: A380, A360.

- Good For:Lightweight parts that need to be strong, like housings for outdoor gear or aerospace components. Our A380 aluminum die cast part manufacturing is very popular for tough electronics and automotive parts.

③Magnesium Alloys

Magnesium is the lightest structural metal available. It has an incredible strength-to-weight ratio.

- Common Alloys: AZ91D.

- Good For:Any part where extreme weight reduction is the most important goal, like in drones, portable electronics, and high-performance automotive components.

6.People Also Ask (FAQ)

Here are some quick answers to common questions.

1.How do an secondary slide work in a die cast mold?

A secondary slide is a moving piece of the mold that is not one of the main halves. It’s pushed into place before the molten metal is injected and pulled out before the part is ejected. This movement is what creates an undercut or side hole that would otherwise trap the part in the mold.

2.What are common issues with slide action die casting?

If you don’t work with an expert, you can run into problems like small leaks (flash) at the slide seams, slides wearing out too fast, or slides moving in the wrong order, which can break the tool. At Welleshaft, we know how to handle troubleshooting die casting machine problems, and our die casting machine maintenance checklist prevents these issues.

3.Can I get a quote for aluminum die casting parts?

Yes. You can get a quote for aluminum die casting parts by contacting our engineers. We provide quotes for zinc and magnesium, too.

7.Work With Welleshaft. Get Your Parts Done Right.

The technology for multi-slide die casting has been around for a while, but Welleshaft has pushed it forward. We don’t just make parts—we work with you from the start. We offer expert DFM advice and help with die casting process parameters optimization to make sure your project is a success.

Stop letting the limits of old manufacturing methods hold you back.

Contact Welleshaft today. Let our engineers show you how multi-slide die casting can improve your product and your process.