Sintered Structure Components:Definition,Processing,Materials,Applications

Definition:

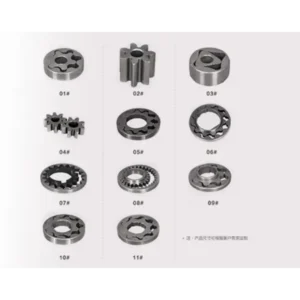

Sintered structural components are intricately designed parts manufactured through the process of powder metallurgy. This advanced manufacturing technique involves compacting metal powders under high pressure and heat, followed by sintering to create dense and intricate shapes with precise dimensional accuracy.

Processing Technique:

At Welle Powder Metallurgy, we employ state-of-the-art powder metallurgy processes to craft sintered structural components and Metallurgy Precision Parts. Our expertise lies in meticulously controlling parameters such as powder composition, compacting pressure, sintering temperature, and duration to ensure optimal mechanical properties and dimensional stability.

Materials:

We utilize a wide range of metal powders, including iron, steel, stainless steel, copper, and alloys, to produce sintered structural components, Copper Base Parts, and Stainless Steel Parts. Each material is carefully selected based on its mechanical properties, corrosion resistance, and suitability for the intended application.

Surface Treatment:

Depending on the application requirements, our sintered structural components can undergo various surface treatments such as Metallurgy Precision Parts Gear Powder Pre-treatment, machining, plating, coating, and heat treatment to enhance their surface properties, improve wear resistance, and achieve specific performance characteristics.

Sintering Manufacturing Process:

The sintering manufacturing process is a critical step in the production of sintered structural components. Our Pressing & Sintering techniques ensure uniform density and strength, resulting in high-quality Sintered Components (Powder Metal) and Powdered Metal Parts.

Quality Requirements:

Welle Powder Metallurgy adheres to stringent quality standards throughout the manufacturing process of sintered structural components. Our quality control measures encompass material inspection, dimensional accuracy checks, mechanical testing, and surface finish evaluation to guarantee impeccable quality and reliability.

Market Applications:

Sintered structural components find widespread applications across various industries, including automotive, aerospace, machinery, electronics, and consumer goods. They are utilized in structural assemblies, transmission systems, powertrain components, actuators, and more where lightweight, high strength, and precision are paramount.

Market Trends and Future Prospects:

The market for sintered structural components is expected to witness significant growth in the coming years.it driven by increasing demand for lightweight, cost-effective, and energy-efficient solutions across industries. Welleshaft Powder Metallurgy is poised to capitalize on this trend by continually innovating and delivering superior Sintered Metal Products, and Sintered metallic components that meet the evolving needs of our customers.

Choose Welle Powder Metallurgy as your trusted partner for high-quality sintered structural components, we can elevate the performance and reliability of your engineering applications.

Reviews

There are no reviews yet.