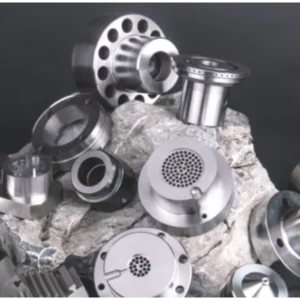

What is CNC Turning?

CNC (Computer Numerical Control) turning is a machining process in which a cutting tool, typically a non-rotary tool bit, moves linearly while the workpiece rotates. The machine tool cuts away material from the rotating workpiece to create cylindrical parts with precise dimensions and smooth finishes.

Types of CNC Turning Operations

1. Straight Turning

Straight turning involves the removal of material along the length of the workpiece, resulting in a uniform cylindrical shape. This basic turning operation is foundational for many machined parts.

2. Taper Turning

Taper turning produces a conical shape on the workpiece by adjusting the angle of the cutting tool relative to the axis of rotation. This operation is essential for components requiring varying diameters along their length.

3. Grooving

Grooving involves cutting a groove or channel into the workpiece. This operation is often used to prepare parts for subsequent operations like threading or to create features for mechanical assembly.

4. Threading

Threading is the process of cutting helical grooves into the workpiece to produce screw threads. This precise operation is critical for fasteners and components that require assembly.

Materials Used in CNC Turning

CNC turning can handle a wide range of materials, including:

Metals: Aluminum, stainless steel, titanium, copper, brass, and magnesium.

Plastics: Nylon, polycarbonate, ABS, PEEK, and more.

Choosing the right material depends on the specific requirements of the project, such as strength, weight, and thermal properties.

Applications of CNC Turned Parts

CNC turned parts are utilized across various industries due to their precision and versatility:

1. Automotive

Engine Components: CNC turning produces high-precision parts like pistons and cylinder heads, enhancing engine performance and efficiency.

Axles and Shafts: Turned shafts and axles are critical for transmitting power and movement in vehicles.

2. Aerospace

Landing Gear: Precision-turned components in landing gear systems ensure safety and reliability.

Turbine Components: CNC turning creates turbine blades and other parts that withstand high temperatures and stresses.

3. Medical

Surgical Instruments: Stainless steel and titanium instruments are turned to high precision for surgical use.

Prosthetics: Biocompatible materials like PEEK and titanium are used to create durable and safe medical implants.

4. Electronics

Connectors: Turned connectors ensure reliable electrical connections in devices.

Housings: CNC turning produces housings that protect sensitive electronic components.

Advantages of CNC Turning

Precision machining: Achieves tight tolerances and intricate details.

Repeatability: Ensures consistent quality across multiple parts.

Flexibility: Can handle complex designs and a variety of materials.

Efficiency: Reduces production time and minimizes waste.

Custom and Production Turning Services

CNC turning companies offer a range of services, from prototype machining to large-scale production machining. Whether you need custom machining for unique projects or production machining for high-volume manufacturing, CNC turning companies can meet your needs. Additionally, CNC Turning China provides cost-effective solutions for global markets.

Is My Part a Good Fit for CNC Turning?

Determining if your part is a good fit for CNC turning depends on several factors:

Geometry: CNC turning is ideal for parts with cylindrical shapes or features.

Material: A wide variety of metals and plastics can be efficiently machined using CNC turning.

Tolerance: If your part requires high precision and tight tolerances, CNC turning is a suitable method.

Volume: CNC turning is effective for both low and high-volume production, making it flexible for different manufacturing needs.

Conclusion

CNC turning is a versatile and reliable manufacturing process, essential for producing high-quality components across various industries. Its ability to work with different materials and deliver precise, repeatable results makes it invaluable in modern manufacturing.

Reviews

There are no reviews yet.