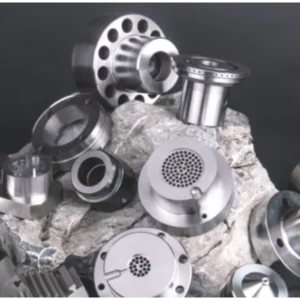

CNC Lathe Machining Processes:An Overview

What is the CNC Lathe Machining?

CNC lathe machining is a versatile and precise manufacturing process widely used across various industries. Understanding the different types of CNC lathe machining processes can help manufacturers select the most suitable method for their specific applications. Here’s an overview of the primary CNC lathe machining processes.

What are the Types of CNC Lathe Machining Processes?

1. Turning

Turning is the fundamental CNC lathe process where a cutting tool removes material from the outer diameter of a rotating workpiece. And It creates cylindrical parts and can produce features such as grooves, tapers, and contours. Turning is commonly used for creating shafts, rods, and custom cylindrical components.

2. Facing

Facing involves cutting across the end of the workpiece to create a flat surface. This process is typically performed at the beginning or end of a turning operation to ensure the workpiece has a smooth and accurate end surface.

3. Parting/Cutting Off

Parting is the process of cutting a part from the main workpiece. This is often used to separate completed parts from the raw material or to create multiple sections from a single piece of material.

4. Grooving

Grooving involves cutting a narrow channel or groove on the workpiece. This process is essential for creating features like O-ring seats, retaining rings, and various other precision grooves.

5. Threading

Threading on a CNC lathe involves creating screw threads on the external or internal surfaces of a workpiece. CNC lathes can produce precise and uniform threads, making them ideal for components requiring threaded connections.

6. Boring

Boring is the process of enlarging an existing hole in the workpiece. This method is used to achieve precise inner diameters and is commonly used in the manufacturing of engine cylinders and other components requiring accurate internal diameters.

7. Drilling

Drilling on a CNC lathe involves creating holes in the workpiece using a rotating cutting tool. This process can be performed axially or radially and is essential for creating holes for fasteners, pins, and other features.

8. Knurling

Knurling is the process of creating a textured pattern on the surface of the workpiece. This is typically done for grip purposes on handles, knobs, and other parts where a secure grip is required.

9. Taper Turning

Taper turning involves creating a conical shape on the workpiece by gradually decreasing the diameter along its length. This process is often used for creating tools, machine components, and other parts that require tapered surfaces.

Applications of CNC Lathe Machining

CNC lathe machining is used in various industries, including automotive, aerospace, medical, and manufacturing. Typical applications include:

- Automotive Parts: Shafts, gears, and engine components.

- Aerospace Components: Turbine blades, landing gear parts, and fasteners.

- Medical Devices: Surgical instruments, implants, and prosthetics.

- General Manufacturing: Custom machined parts, prototypes, and production runs.

Advantages of CNC Lathe Machining

- Precision: CNC lathes provide high accuracy and repeatability, ensuring consistent part quality.

- Efficiency: Automated processes reduce manual intervention, increasing production speed and efficiency.

- Versatility: CNC lathes can handle a wide range of materials and complex geometries.

- Cost-Effective: Reduced labor costs and material waste lead to cost savings in production.

Challenges of CNC Lathe Machining

- Initial Setup Cost: High initial investment in CNC machinery and programming can be a barrier for some businesses.

- Skilled Labor: Operating and programming CNC lathes require skilled technicians and engineers.

- Maintenance: Regular maintenance and calibration are necessary to maintain accuracy and prolong machine life.

By understanding these processes and their applications, manufacturers can leverage CNC lathe machining to produce high-quality components efficiently and cost-effectively.

Reviews

There are no reviews yet.