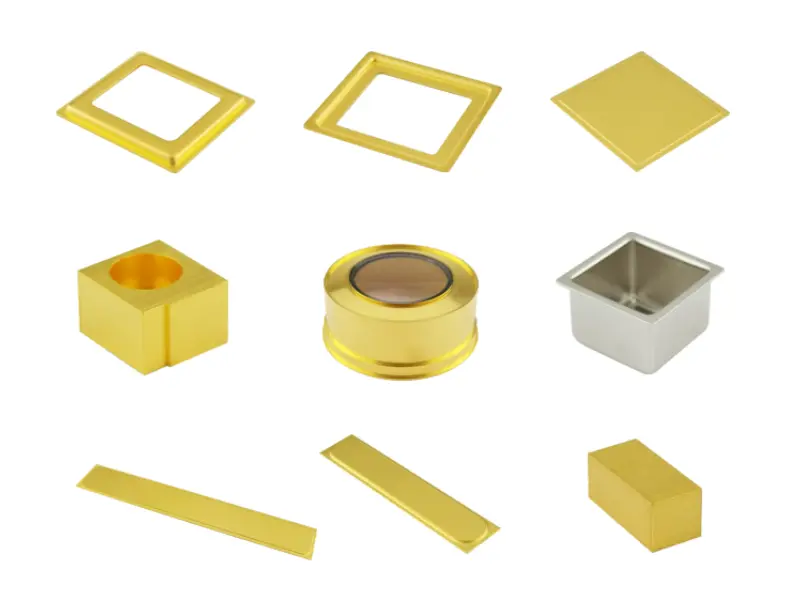

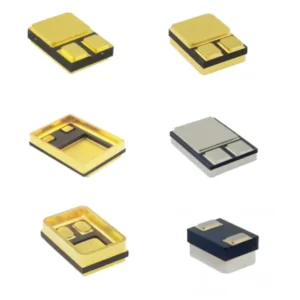

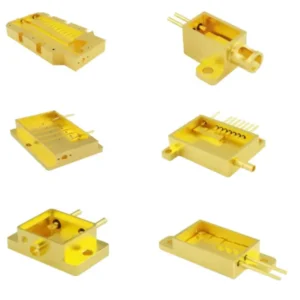

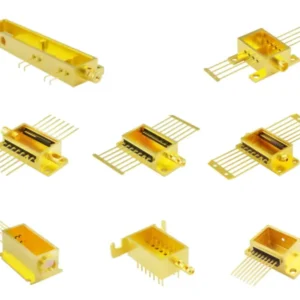

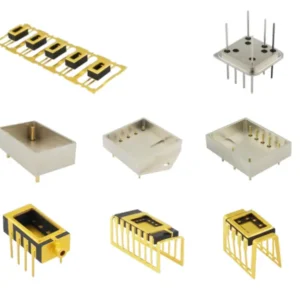

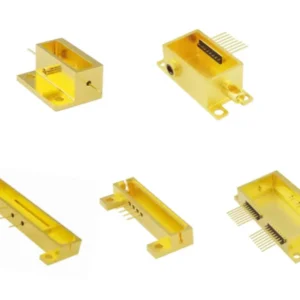

SMD Metal Upper Cover Components:An Overview

What is the SMD Metal Upper cover components?

Processing Techniques of SMD Metal Upper cover

Suitable Enclosure Materials of SMD Metal Upper Cover

Our SMD Metal Upper Cover Components are crafted from high-quality materials such as Kovar, copper, aluminum, and stainless steel. These materials offer excellent thermal conductivity, mechanical strength, and corrosion resistance, ensuring durability and longevity in demanding environments.

Comprehensive Coating Processes of SMD Metal Upper Cover

To enhance functionality and durability, our SMD Metal Upper Cover Components undergo advanced coating processes such as gold plating, zinc-nickel alloy coating, and gold-tin composite plating. These coatings provide superior corrosion resistance, solderability, and electrical conductivity, ensuring optimal performance in varied applications.

Reviews

There are no reviews yet.