RF and Microwave ceramic packages:An Overview

Welle Hermetic Packages is at the forefront of delivering exceptional RF and Microwave ceramic packaging solutions, setting the standard for reliability, performance, and innovation. Here’s why our RF and Microwave ceramic packaging stands out:

Understanding of RF and Microwave ceramic packages:

RF and Microwave ceramic packaging involves the encapsulation and protection of RF (Radio Frequency) and Microwave electronic components within hermetic ceramic enclosures. These packages ensure optimal performance and reliability of critical RF and Microwave systems by shielding sensitive components from environmental factors.

Advanced Processing Techniques of RF and Microwave ceramic packages:

Leveraging state-of-the-art manufacturing processes, we employ advanced techniques such as precision machining, laser cutting, and microfabrication to produce RF and Microwave ceramic packages with exceptional precision and consistency. Our expertise ensures seamless integration of electronic components, maintaining alignment and functionality.

Suitable Enclosure Materials of RF and Microwave ceramic packages:

We offer a range of high-performance materials for RF and Microwave ceramic packaging, including High-Temperature Co-Fired Ceramic (HTCC), Low-Temperature Co-Fired Ceramic (LTCC), and specialty ceramics optimized for RF and Microwave applications. These materials provide excellent thermal stability, electrical insulation, and mechanical strength, essential for demanding RF and Microwave environments.

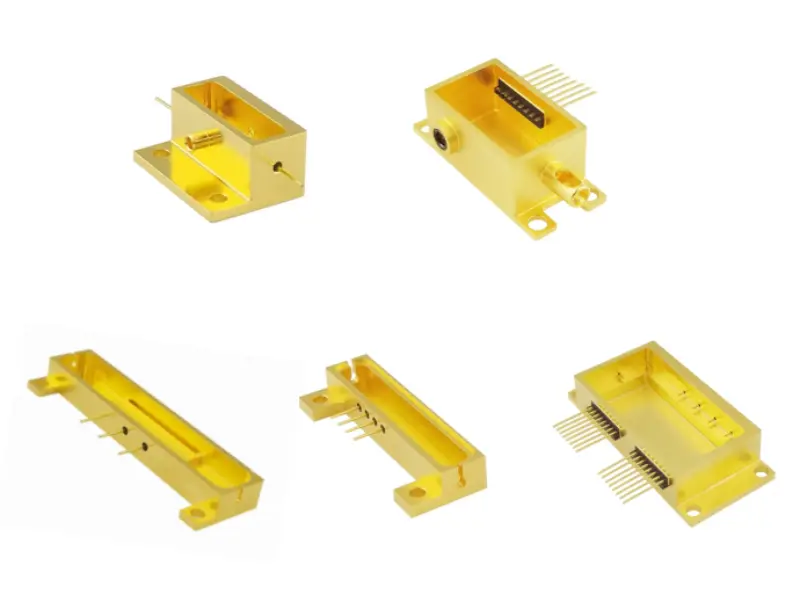

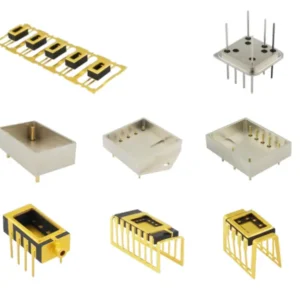

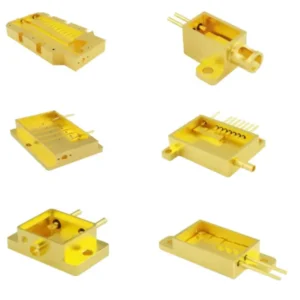

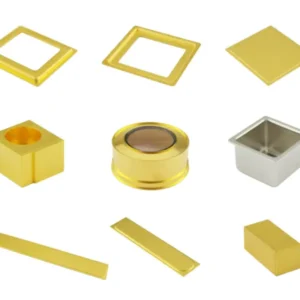

Plating Processes of RF and Microwave ceramic packages:

To enhance the performance and durability of RF and Microwave ceramic packages, we employ various plating processes such as gold plating, nickel plating, and solder mask deposition. These processes provide corrosion resistance, solderability, and electrical conductivity, ensuring robust interconnectivity and reliability.

Welding Techniques of RF and Microwave ceramic packages:

Our hermetic packages feature robust welding techniques such as laser welding and seam sealing to achieve reliable and leak-free seals. Hermetic sealing of RF and Microwave ceramic packages ensures the long-term integrity and protection of sensitive electronic components, even in harsh operating conditions.

Quality Standards of RF and Microwave ceramic packages:

Quality is paramount in every aspect of our manufacturing process. We adhere to rigorous quality control measures, conducting thorough inspections and testing to guarantee the hermeticity, dimensional accuracy, and reliability of our RF and Microwave ceramic packages.

Applications of RF and Microwave ceramic packages:

Our RF and Microwave ceramic packages find extensive applications in various industries, including telecommunications, aerospace, defense, and medical devices. From satellite communication systems to radar sensors, our packages play a crucial role in enabling high-performance RF and Microwave electronic systems.

Post-2024 Market Trends: Looking ahead, the RF and Microwave ceramic packaging market is poised for significant growth, driven by the increasing demand for high-frequency communication systems, 5G technology, and Internet of Things (IoT) devices. Welle Hermetic Package manufacturer is committed to leading this growth by continuously innovating and offering tailored solutions to meet evolving market needs.

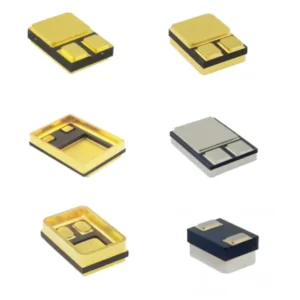

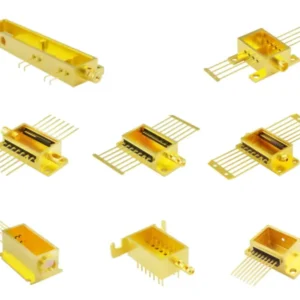

Product Features of RF and Microwave ceramic packages:

Exceptional Hermetic Sealing: Our RF and Microwave ceramic packages provide a high level of hermeticity, ensuring reliable protection of enclosed electronic components against moisture, dust, and other environmental hazards.

Enhanced Thermal Management: Designed to dissipate heat efficiently, our packages offer excellent thermal conductivity, preventing overheating and ensuring stable RF and Microwave performance.

Miniaturization and High Integration: With a focus on compact design and high integration, our packages enable the miniaturization of RF and Microwave systems without compromising functionality or reliability.

Elevate precision and performance with Welle’s RF and Microwave Ceramic Packaging solutions. Trust us to deliver superior quality and reliability for your RF and Microwave electronic applications.

Reviews

There are no reviews yet.