Quartz Micromachining:An Overview

What is the micro machining?

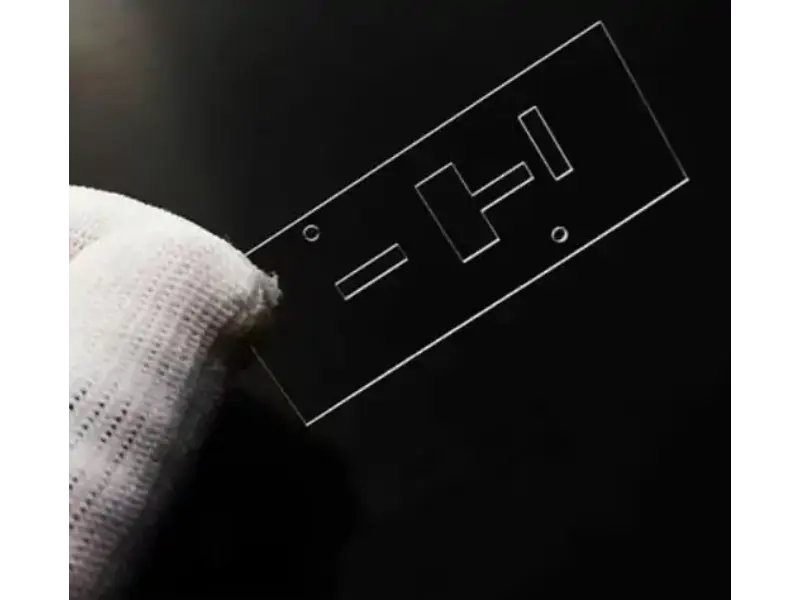

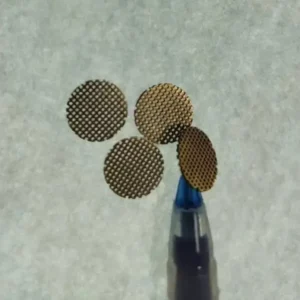

- Quartz glass micro machining involves the precise fabrication of intricate components and structures on quartz glass substrates using advanced machining techniques. It enables the creation of micro-scale features with high precision and accuracy.

How do the Processing of Quartz micromachining?

- CNC Machining: Utilizes computer-controlled machines to perform precise cutting, milling, and drilling operations on quartz glass plates, ensuring consistent and accurate results.

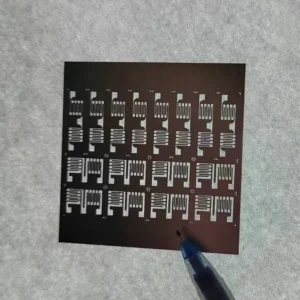

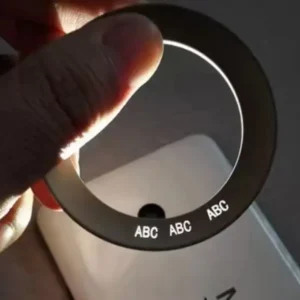

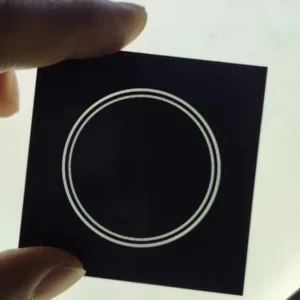

- Laser Cutting, Drilling, & Milling: Employs laser technology to cut, drill, and mill quartz glass with micron-level precision, offering versatility and flexibility in micro-scale machining.

- Ultrasonic Machining: Utilizes ultrasonic vibrations to remove material from quartz glass substrates, enabling precise shaping and profiling of microstructures.

Micromachining Applications in Semiconductor and Optical Industries

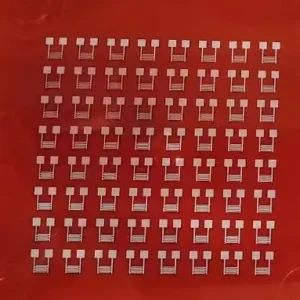

- Quartz machining plays a crucial role in semiconductor and optical industries for fabricating components such as micro lenses, waveguides, sensor substrates, and photonic devices.

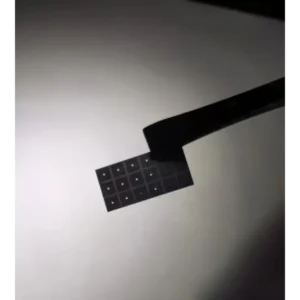

- Micro drilling of quartz is essential for creating precise channels, vias, and holes in semiconductor substrates for integrated circuitry and microfluidic applications.

How are the Performance Enhancement of quartz micro-machining?

- Ongoing research focuses on improving quartz micro-machining performance by optimizing machining parameters, tool designs, and process parameters to achieve higher accuracy, efficiency, and surface quality.

- Studies explore the influence of tool inclination, machining strategies, and tool-material interactions on the quality and precision of machined quartz components.

What’s the types of Micro Machining Services?

-

Specialized micro machining services offer custom solutions for micro milling, drilling, and surface patterning on quartz glass substrates, catering to the unique requirements of semiconductor, optical, and microelectronics industries.

-

Laser micromachining services provide high-resolution fabrication of intricate features on quartz glass, silicon, and ceramics, meeting the demands of advanced microfabrication processes.

How about of the Market Trends of quartz micro machining processes?

- The demand for quartz glass micro machining is expected to rise steadily, driven by advancements in microelectronics, photonics, and biomedical applications.

- Technological innovations in laser micromachining and CNC machining will continue to enhance precision, speed, and scalability in quartz glass fabrication.

- Increasing adoption of microfluidic devices, MEMS sensors, and optical components will fuel the demand for high-precision quartz micro machining services, driving market growth in the coming years.

Reviews

There are no reviews yet.