Optical fibers laser drilling services:An Overview

What is the Optical Fibers Laser Drilling Micro holes?

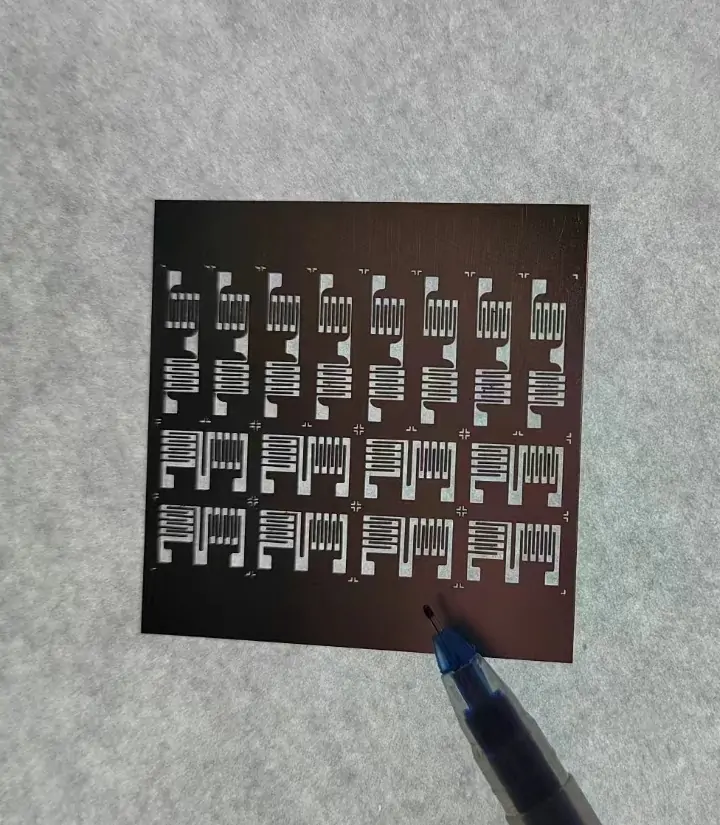

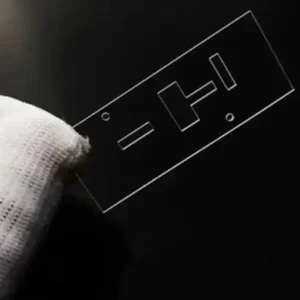

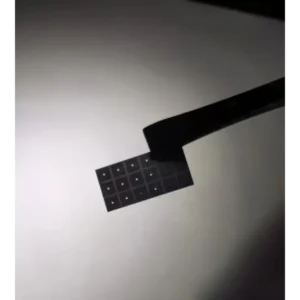

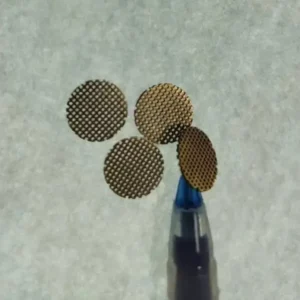

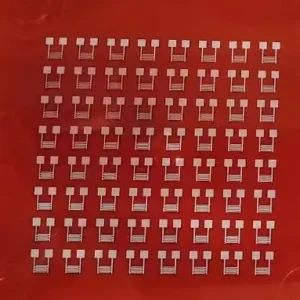

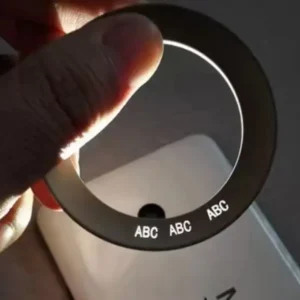

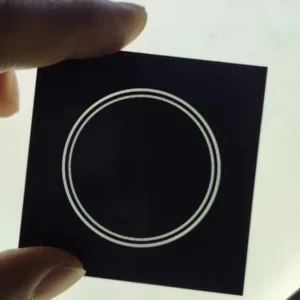

Optical Fibers Laser Drilling Micro holes is a specialized technique that involves the precise drilling of micro-sized holes in optical fiber materials using advanced laser technology. It enables the creation of intricate structures and features essential for a wide range of applications in industries such as telecommunications, fiber optics, and optical sensors.

How do the Processing of Optical fiber lasers and femtosecond laser technology?

Leveraging the power of Optical fiber lasers and femtosecond laser technology, our Laser Micro Drilling process achieves unparalleled precision and control. From Micro-drilled optical fibers to laser-drilled free-form silica fiber, our capabilities extend to drilling micro-holes in any material with exceptional accuracy and reproducibility.

What are the Materials of Laser micro drilling?

Our expertise in Laser Micro Drilling spans across a variety of materials, including glass fiber reinforced polymer composites, microstructured polymer optical fibers, and Microstructured Optical Fibers. Whether it’s drilling micro-holes in traditional optical fibers or pushing the boundaries with innovative materials, we deliver results that exceed expectations.

Where of the Laser micro drilling applications?

The applications of Laser Micro Drilling in Optical Fibers are vast and diverse. From enhancing the performance of fiber optic communication systems to enabling the development of advanced optical fiber-based sensors, our precision-drilled fibers pave the way for breakthroughs in various industries. Whether it’s creating microstructured optical fibers for biomedical imaging or optimizing fiber optics for data transmission, the possibilities are endless.

What’s the Industries of optical fibers components?

As demand for high-performance optical fibers continues to rise, the future of Laser Micro Drilling is brighter than ever. From Micro Hole Drilling to femtosecond laser microhole drilling, the quest for smaller, more intricate structures drives innovation and propels the industry forward. With our expertise and commitment to excellence, Welle is poised to lead the charge in shaping the future of Optical Fibers Laser Micro Drilling.

Join us on the journey towards precision perfection. Together, let’s unlock the full potential of Optical Fibers Laser Micro Drilling and pave the way for a future illuminated by innovation and excellence.

Reviews

There are no reviews yet.