Spur Gears:An Overview

What Are Spur Gears?

Spur gears are the most common type of gears, characterized by straight teeth that are parallel to the gear’s axis. They are used to transmit motion and power between parallel shafts.

What Materials Are Used for Spur Gears?

Spur gears can be made from a variety of materials, each offering specific characteristics suited to different applications:

Alloy Steel: Known for high strength and durability, making it ideal for heavy-duty applications.

Carbon Steel: Provides a good balance of strength and cost-effectiveness.

Stainless Steel: Offers corrosion resistance and is suitable for environments where rust is a concern.

Cast Iron: Cost-effective and robust, often used in larger gears.

Brass: Good for applications requiring lower friction and where aesthetics are important.

What Is the Gear Machining Process for Spur Gears?

The gear machining process for spur gears involves several precise steps:

Design and Modeling: Using CAD software to create a detailed design.

Material Selection: Choosing the appropriate material based on application requirements.

Cutting and Shaping: Using methods such as hobbing, milling, or shaping to cut the gear teeth.

Heat Treatment: Hardening the gear material to improve durability and wear resistance.

Finishing: Grinding, lapping, or polishing to achieve the desired surface finish and dimensional accuracy.

Inspection and Quality Control: Ensuring the gears meet all specifications and standards.

What Are the Types of Spur Gears?

Spur gears come in various types, including:

Internal Spur Gears: Teeth are cut on the inside of the cylinder, meshing with external spur gears.

External Spur Gears: Teeth are cut on the outside of the cylinder.

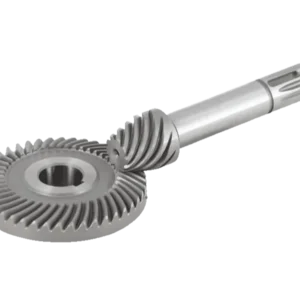

Helical Spur Gears: Modified spur gears with angled teeth to provide smoother operation and higher load capacity.

What Are Common Spur Gear Terms?

Understanding spur gear terminology is crucial for precise communication and design:

Pitch Diameter: The diameter of the pitch circle where the gear teeth effectively mesh.

Pressure Angle: The angle between the line of action and the line perpendicular to the pitch surface.

Module: Metric unit of measurement representing the size of the gear teeth.

Diametral Pitch: Imperial unit of measurement representing the number of teeth per inch of pitch diameter.

Backlash: The slight gap between meshing teeth to allow for lubrication and thermal expansion.

How Are Spur Gears Produced?

Spur gears are produced through several methods, including:

Hobbing: The most common method, involving a hob cutting tool that progressively cuts the gear teeth.

Milling: Using a milling machine to cut the teeth one at a time.

Shaping: A gear shaper machine cuts the teeth by reciprocating motion.

Grinding: Used for fine finishes and high precision, particularly in hardened gears.

What Are the Tool Costs for Spur Gear Production?

Tool costs for spur gear production can vary based on several factors:

Material: The cost of the raw material chosen for the gears.

Tooling: The cost of cutting tools and machinery required for manufacturing.

Precision Requirements: Higher precision gears require more sophisticated tools and processes, increasing costs.

Volume: Higher production volumes can reduce per-unit tooling costs due to economies of scale.

What Are the Benefits of Spur Gears?

Spur gears offer numerous benefits, including:

Simplicity: Easy to design and manufacture.

Efficiency: High efficiency in transmitting power between parallel shafts.

Durability: Strong and long-lasting, especially when made from high-quality materials.

Versatility: Suitable for a wide range of applications and industries.

Cost-Effective: Generally less expensive to produce compared to more complex gear types.

What Are the Applications of Spur Gears?

Spur gears are used in a wide array of applications, such as:

Automotive: Transmissions, gearboxes, and differentials.

Industrial Machinery: Conveyors, presses, and packaging machines.

Aerospace: Actuators, control systems, and landing gear.

Robotics: Motion control and actuation systems.

Marine: Propulsion systems and deck machinery.

Consumer Electronics: Printers, clocks, and other devices requiring precise motion control.

Why Choose Welleshaft for Your Spur Gear Needs?

Choosing Welleshaft for your spur gear requirements offers several advantages:

Expertise: Decades of experience in high-precision gear manufacturing.

Advanced Technology: Use of cutting-edge manufacturing techniques and equipment.

Customization: Ability to create bespoke solutions tailored to your specific needs.

Quality Assurance: Commitment to stringent quality standards for reliable and durable gears.

Customer Support: Dedicated service and support throughout the entire process, from design to delivery.

By understanding the intricacies and advantages of spur gears, you can make informed decisions for your mechanical systems, ensuring optimal performance and reliability. Choosing Welleshaft guarantees access to high-quality, custom-tailored spur gears backed by decades of experience and advanced technology.

.

Reviews

There are no reviews yet.