Hybrid Packages (Multi-Chip Module):An Overview

At Welle Hermetic Packages, we specialize in crafting state-of-the-art Hybrid Packages, including Multi-Chip Modules (MCMs), designed to meet the highest standards of reliability, functionality, and versatility. Here’s why our Hybrid Package – MCM stands out in the industry:

Understanding of Hybrid Packages:

A Hybrid Package – Multi-Chip Module (MCM) is a sophisticated electronic packaging solution that integrates multiple semiconductor chips and passive components within a single enclosure. This compact and efficient design optimizes space utilization while enhancing performance and functionality.

Advanced Processing of Hybrid Packages:

Leveraging advanced manufacturing processes, including precision machining, laser cutting, and microfabrication, we ensure precise integration and assembly of semiconductor chips and passive components within the Hybrid Package – MCM. Our expertise guarantees seamless functionality and compatibility across all components.

Versatile Enclosure Materials of Hybrid Packages:

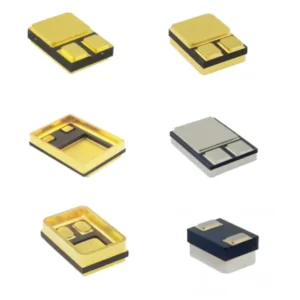

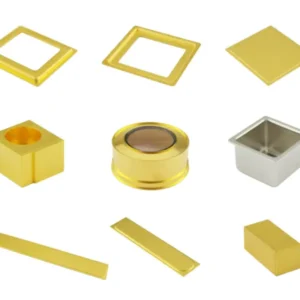

Our Hybrid Packages – MCMs are available in a wide variety of materials, including metal, ceramic, and hybrid microcircuits. Whether you require the robustness of metal enclosures or the thermal properties of ceramic substrates, we offer customized solutions tailored to your specific needs.

Coating Processes of Hybrid Packages:

To enhance durability and performance, our Hybrid Packages – MCMs undergo advanced coating processes such as gold plating, nickel plating, and solder mask deposition. These coatings provide superior corrosion resistance, solderability, and electrical conductivity, ensuring reliable interconnectivity and longevity.

Welding Techniques of Hybrid Packages:

Our Hybrid Packages – MCMs feature robust welding techniques, including hermetic sealing and soldering, to achieve secure and reliable connections between semiconductor chips and passive components. These welding methods ensure the integrity and hermeticity of the package, protecting sensitive electronic components from environmental hazards.

Quality Standards of Hybrid Packages:

Quality is our top priority. We adhere to rigorous quality control measures throughout the manufacturing process, conducting thorough inspections and testing to guarantee the reliability, durability, and performance of our Hybrid Packages – MCMs.

Applications of Hybrid Packages:

Our Hybrid Packages – MCMs find extensive applications across various industries, including aerospace, telecommunications, automotive, and consumer electronics. From advanced communication systems to sophisticated medical devices, our packages cater to a wide range of demanding applications.

Advantages of Hybrid Packages:

Hybrid Packages offer several advantages, including enhanced integration capabilities, improved thermal management, and reduced form factor. By combining different packaging technologies, Hybrid Packages enable the integration of diverse components in a compact and efficient manner, enhancing overall system performance.

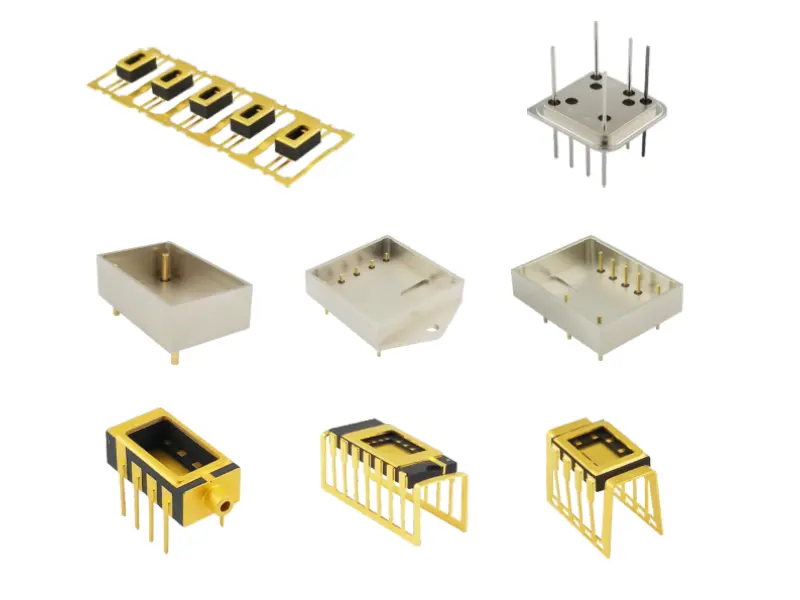

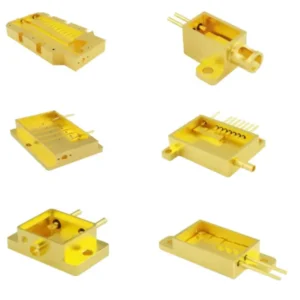

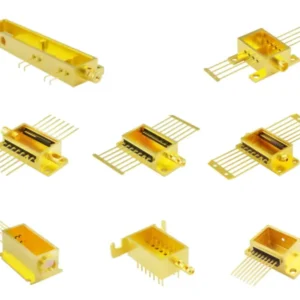

Wide Variety of Package Configurations and Lead Counts:

We offer a wide range of package configurations and lead counts to accommodate diverse application requirements. Whether you need a standard package or a customized solution, we provide flexible options to meet your specific needs.

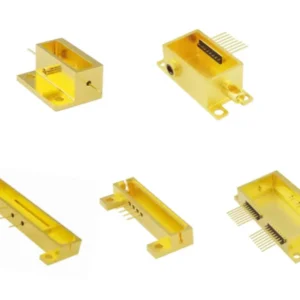

Packages Available in Various Styles:

Our Hybrid Packages – MCMs are available in metal, DIP style, and Flat Pack configurations, offering versatility and flexibility to suit different application scenarios. Whether you prefer traditional DIP-style packages or modern Flat Pack designs, we have the solution for you.

Hermetic Sealing:

Our Hybrid Packages feature hermetic sealing, ensuring the long-term reliability and protection of enclosed components against moisture, dust, and other environmental factors. Hermetic sealing preserves the integrity of sensitive electronic components, ensuring consistent performance over time.

Microelectronic Metal & Ceramic Packages:

We specialize in manufacturing microelectronic packages using both metal and ceramic materials, offering customized solutions to meet the unique needs of each application. Our metal and ceramic packages provide excellent thermal conductivity, electrical insulation, and mechanical strength, essential for high-performance electronic systems.

Hybrid Integrated Circuit Packages:

Our Hybrid Packages – MCMs are designed to accommodate hybrid integrated circuits, enabling the integration of different semiconductor technologies within a single package. This integration enhances functionality and performance while reducing system complexity and footprint.

Ceramic Substrate/Package:

With our expertise in ceramic packaging technologies, we offer ceramic substrate/package solutions tailored to your specific requirements. Our ceramic packages provide excellent thermal management, electrical insulation, and mechanical robustness, making them ideal for demanding applications in RF and Microwave, power electronics, and more.

Reviews

There are no reviews yet.