Worm and Wheel:An Overview

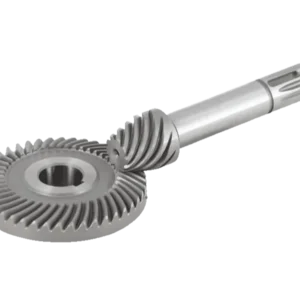

What is a Worm Gear?

A worm gear is a specific type of gear that consists of a worm (which is similar to a screw) and a worm wheel (a gear similar to a spur gear). This gear arrangement allows for high torque and large speed reduction ratios, making it ideal for various applications where space is limited and efficient power transmission is required.

What Materials Are Used for Worm Gears?

Worm gears can be made from various materials, each offering unique characteristics:

Steel: High strength and durability, used for heavy-duty applications.

Bronze: Good wear resistance and reduced friction, often used for the worm wheel to improve the gear set’s longevity.

Nylon: Lightweight and quiet operation, suitable for low-load applications.

Cast Iron: High durability and cost-effective for larger gears.

Phosphor Bronze: Excellent wear resistance and strength, typically used for high-performance applications.

How Do Worm Gears Work?

Worm gears operate by the worm (which resembles a screw) meshing with the worm wheel. When the worm rotates, it drives the worm wheel, causing it to turn. The design allows for significant speed reduction and increased torque. The unique feature of worm gears is their self-locking ability, preventing back-driving in certain applications.

Are Worm Gears Available in Both Inch and Metric Sizes?

Yes, worm gears are available in both inch and metric sizes to cater to different design standards:

Inch Gears: Measured in inches, commonly used in the United States and countries that follow Imperial measurement standards.

Metric Gears: Measured in millimeters, commonly used in Europe and countries that follow the Metric system.

What Are the Types of Worm Gears?

Worm gears come in various types, including:

Single-Start Worms: The most common type, featuring a single thread on the worm.

Multi-Start Worms: Multiple threads on the worm, allowing for faster engagement and higher speeds.

Throated Worms: Curved gear teeth for increased contact and load capacity.

Non-Throated Worms: Straight gear teeth for simpler, lower-load applications.

Should You Choose Standard or Customised Worm Gears?

Standard Worm Gears: Off-the-shelf solutions suitable for general applications. They are cost-effective and readily available.

Customised Worm Gears: Tailored to specific design requirements and applications, offering optimal performance for specialized needs.

What Are the Tool Costs for Manufacturing Worm Gears?

Tooling costs for worm gear manufacturing can vary based on several factors:

Mold Design: Initial mold creation can be expensive due to the precision required.

Material Selection: Different materials may require specific tooling adjustments, impacting costs.

Production Volume: Higher production volumes can offset initial tooling expenses, reducing the cost per part.

What Are the Benefits of Worm Gears?

Worm gears offer numerous advantages:

High Torque Output: Capable of generating high torque from a small package.

Speed Reduction: Effective at achieving large speed reductions in a compact design.

Self-Locking: Prevents back-driving in certain applications, adding a safety feature.

Smooth and Quiet Operation: Reduced noise and vibration compared to other gear types.

Compact Design: Suitable for applications with space constraints.

What Are the Applications of Worm Gears?

Worm gears are used in various industries, including:

Automotive: Power steering systems, winches, and lifts.

Industrial Machinery: Conveyors, hoists, and machine tools.

Consumer Electronics: Elevators, lifts, and actuators.

Robotics: Drive systems and precision movements.

Marine: Steering mechanisms and deck machinery.

What Tips Should Be Followed When Using Worm Gears?

When using worm gears, consider the following tips:

Proper Lubrication: Ensure adequate lubrication to reduce friction and wear.

Avoid Overloading: Design the gear system to handle the expected loads to prevent failure.

Regular Maintenance: Periodic inspection and maintenance to ensure longevity and optimal performance.

Correct Alignment: Ensure proper alignment of the worm and worm wheel to avoid undue stress and wear.

What Are Worm Gear Worm Wheels?

The worm gear worm wheel is a gear set comprising the worm (a gear in the form of a screw) and the worm wheel (a gear resembling a spur gear). This combination allows for significant torque multiplication and speed reduction in a compact form.

How Do Different Kinds of Gears Compare?

Worm gears differ from other gears such as spur gears, helical gears, and bevel gears in their unique ability to achieve high torque and large speed reductions in compact spaces. They also offer the advantage of self-locking, which is not typically found in other gear types.

What Unique Features and Applications Do Worm Gears Offer?

Worm gears are uniquely suited for applications requiring:

High Torque and Compact Size: Efficient power transmission in small spaces.

Non-Reversible Movement: Preventing back-driving for added safety.

Smooth and Quiet Operation: Ideal for noise-sensitive environments.

What Considerations Should Be Made When Choosing Worm Gears?

Consider the following when choosing worm gears:

Load Requirements: Ensure the gear material and design can handle the required load.

Environmental Conditions: Consider temperature, humidity, and chemical exposure.

Longevity: Choose materials and designs that offer the required lifespan for the application.

Compatibility: Ensure the gear set fits seamlessly into the existing mechanical system.

What is the Critical Gear Data for Worm Gear and Worm Wheel Sets?

Critical data for worm gear and worm wheel sets includes:

Center Distance: The distance between the worm and worm wheel axes.

Lead Angle: The angle between the helix of the worm thread and a plane perpendicular to the worm axis.

Pitch Diameter: The diameter of the pitch circle in the worm and worm wheel.

Module (Metric) or Diametral Pitch (Inch): Represents the gear size, module in metric and diametral pitch in inch measurements.

Pressure Angle: The angle between the line of action and the line perpendicular to the pitch surface.

Number of Starts (Threads): The number of helical threads on the worm.

Gear Ratio: The ratio of the number of teeth on the worm wheel to the number of starts on the worm.

Tooth Profile: The shape of the gear teeth, which can affect efficiency and load capacity.

Backlash: The clearance between the mating gear teeth.

Why Choose Welleshaft for Your Worm Gear Needs?

Choosing Welleshaft offers several benefits:

Expertise: Decades of experience in gear manufacturing.

Quality: Commitment to high-quality standards and precision.

Customization: Ability to create bespoke solutions tailored to your requirements.

Technology: Utilization of advanced manufacturing techniques and equipment.

Customer Support: Dedicated service and support throughout the entire process, from design to delivery.

By understanding the intricacies and advantages of worm gears, you can make informed decisions for your applications, ensuring the best quality and performance for your products.

WORM AND WORM SHAFTS CATELOG

-

Standard and Customized Worm Gear Catelogy

-

Standard and Custmoized Worm Shaft Catelogy

-

Worm and Worm Gears Catelogy

-

Dual Lead Worm Gear Catelogy

Reviews

There are no reviews yet.