Miter Gear:An Overview

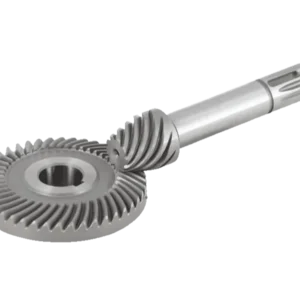

What Are Miter Gears?

Miter gears are a type of bevel gear where the two mating gears have an equal number of teeth and are mounted on shafts that intersect at a 90-degree angle. They are typically used to change the direction of a shaft’s rotation without altering the speed or torque.

What Materials Are Used for Miter Gears?

Miter gears can be manufactured from a variety of materials, each suited for specific applications:

- Steel: High strength and durability, commonly used for heavy-duty applications.

- Stainless Steel: Offers corrosion resistance, ideal for harsh environments.

- Cast Iron: Cost-effective and strong, used for larger gears.

- Brass: Good for lower loads and where reduced friction is beneficial.

How Do Miter Gears Work?

Miter gears work by meshing their teeth at a 90-degree angle. This design allows for the smooth transmission of power and motion between two intersecting shafts. The gears have an identical number of teeth, ensuring a 1:1 gear ratio, which means there is no change in speed or torque.

Are Miter Gears Available in Both Inch and Metric Sizes?

Yes, miter gears are available in both inch and metric sizes to accommodate different design standards:

- Inch Gears: Measured in inches, commonly used in the United States and countries that follow Imperial measurement standards.

- Metric Gears: Measured in millimeters, commonly used in Europe and countries that follow the Metric system.

What Are the Types of Miter Gears?

Miter gears come in several types, including:

- Straight Miter Gears: The most common type, with straight teeth.

- Spiral Miter Gears: Have curved teeth that provide smoother and quieter operation.

- Zerol Miter Gears: A variation of spiral miter gears with a zero-degree spiral angle.

Should You Choose Standard or Customised Miter Gears?

Standard Miter Gears: Off-the-shelf solutions suitable for general applications. They are cost-effective and readily available.

Customised Miter Gears: Tailored to specific design requirements and applications, offering optimal performance for specialized needs.

What Are the Tool Costs for Manufacturing Miter Gears?

Tooling costs for miter gear manufacturing can vary based on several factors:

- Design Complexity: More complex designs can increase tooling costs.

- Material Selection: Different materials may require specific tooling adjustments, impacting costs.

- Production Volume: Higher production volumes can offset initial tooling expenses, reducing the cost per part.

What Are the Benefits of Miter Gears?

Miter gears offer numerous advantages:

- Efficient Power Transmission: Effective at changing the direction of rotation with minimal loss.

- Compact Design: Suitable for applications with space constraints.

- Versatile: Can be used in a wide range of applications.

- High Load Capacity: Capable of handling significant loads.

- Durability: Long-lasting and reliable in demanding applications.

What Are the Applications of Miter Gears?

Miter gears are used in various industries, including:

- Automotive: Differential systems and steering mechanisms.

- Industrial Machinery: Conveyors, mixers, and machine tools.

- Aerospace: Actuators and control systems.

- Robotics: Precision motion control.

- Marine: Propulsion systems and steering gear.

What Tips Should Be Followed When Using Miter Gears?

When using miter gears, consider the following tips:

- Proper Lubrication: Ensures smooth operation and reduces wear.

- Correct Alignment: Misalignment can cause excessive wear and noise.

- Load Management: Avoid overloading to prevent gear damage.

- Regular Maintenance: Periodic inspections to ensure optimal performance and longevity.

- Temperature Control: Monitor and manage operating temperatures to prevent overheating.

How Do Different Kinds of Gears Compare?

Miter gears differ from other gears such as spur gears, helical gears, and worm gears in several ways:

- Spur Gears: Simple design but only for parallel shafts.

- Helical Gears: For parallel or crossed shafts, with smoother and quieter operation.

- Worm Gears: Achieve high torque and large speed reductions in a compact form.

What Unique Features and Applications Do Miter Gears Offer?

Miter gears are uniquely suited for applications requiring:

- Right-Angle Power Transmission: Ideal for changing the direction of rotation.

- Compact Design: Efficient use of space in mechanical systems.

- Consistent Speed and Torque: Maintains a 1:1 gear ratio without altering speed or torque.

What Considerations Should Be Made When Choosing Miter Gears?

When choosing miter gears, consider the following:

- Load Requirements: Ensure the gear material and design can handle the required load.

- Environmental Conditions: Consider factors such as temperature, humidity, and exposure to chemicals.

- Longevity: Choose materials and designs that offer the required lifespan for the application.

- Compatibility: Ensure the gear set fits seamlessly into the existing mechanical system.

Why Choose Welleshaft for Your Miter Gear Needs?

Choosing Welleshaft offers several benefits:

- Expertise: Decades of experience in gear manufacturing.

- Quality: Commitment to high-quality standards and precision.

- Customization: Ability to create bespoke solutions tailored to your requirements.

- Technology: Utilization of advanced manufacturing techniques and equipment.

- Customer Support: Dedicated service and support throughout the entire process, from design to delivery.

Critical Gear Data for Miter Gear Sets

Critical data for miter gear sets includes:

- Pitch Diameter: The diameter of the pitch circle, determining the gear size.

- Module (Metric) or Diametral Pitch (Inch): Represents the gear size, module in metric and diametral pitch in inch measurements.

- Pressure Angle: The angle between the line of action and the line perpendicular to the pitch surface, impacting the strength and efficiency of the gear set.

- Number of Teeth: Affects the gear ratio and overall dimensions.

- Face Width: The width of the gear teeth, impacting load capacity.

- Backlash: The clearance between the mating gear teeth, affecting precision and noise.

By understanding the intricacies and advantages of miter gears, you can make informed decisions for your applications, ensuring the best quality and performance for your products.

Reviews

There are no reviews yet.