Polymer & plastic Laser micro-cutting: processes,materials and applications

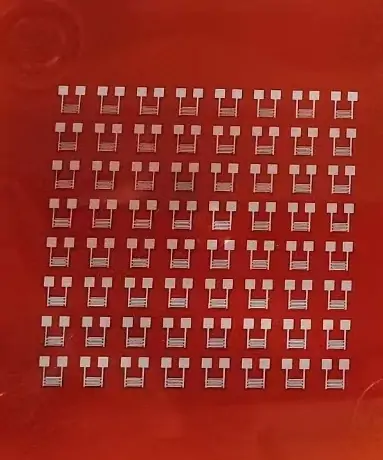

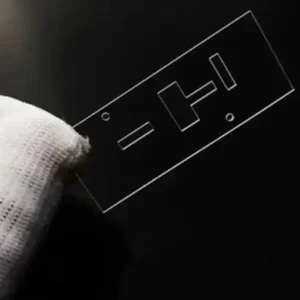

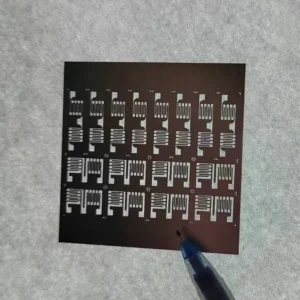

Polymer and plastic laser cutting is an advanced manufacturing process that utilizes laser technology to precisely cut and shape various polymer and plastic materials according to specific designs and dimensions. This technique offers exceptional precision, allowing for intricate details and complex geometries to be achieved with high accuracy and repeatability.

Processing Technique of Laser micro cutting

-

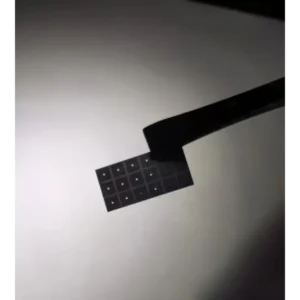

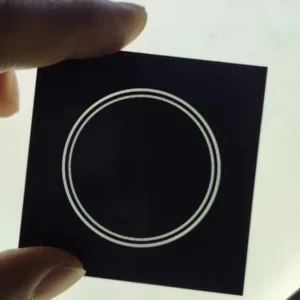

Laser Micro-Cutting: Polymer and plastic materials are subjected to a focused laser beam that selectively melts or vaporizes the material along the designated cutting path. This precise process ensures clean, precise cuts without the need for additional machining or finishing.

Applicable Materials of laser cutting

- Polymer and plastic laser cutting can be applied to a wide range of materials, including but not limited to:

- PVC (Polyvinyl Chloride)

- ABS (Acrylonitrile Butadiene Styrene)

- Nylon

- Polyethylene

- PETG (Polyethylene Terephthalate Glycol)

- PTFE (Polytetrafluoroethylene)

- Polystyrene

- Polyurethane

- PET (Polyethylene Terephthalate)

- FR4

- Delrin

- Peek

- Mylar

- Teflon

- Polycarbonate

Product Features of laser micro cutting

- Precision Cutting: Polymer and plastic laser cutting offers exceptional precision and accuracy, allowing for the creation of intricate designs and complex shapes with minimal material wastage.

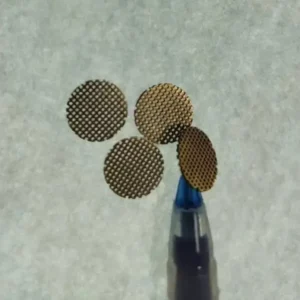

- Smooth Edges: The laser cutting process produces clean, smooth edges without burrs or defects, resulting in high-quality finished parts.

- Versatility: With the ability to cut a wide range of polymer and plastic materials, laser cutting offers versatility in component design and production.

- Non-contact Process: Laser cutting is a non-contact process, minimizing the risk of material deformation or damage, particularly for delicate or heat-sensitive materials.

Main Applications and Market Areas of polymer and plastic Laser cutting

- Polymer and plastic laser cutting finds applications across various industries, including:

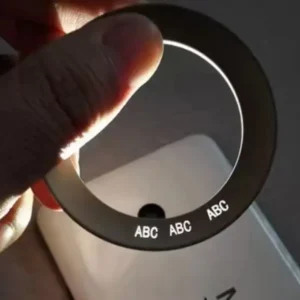

- Electronics: for manufacturing circuit boards, displays, and electronic enclosures.

- Automotive: for producing interior components, dashboards, and exterior trim.

- Medical: for fabricating surgical instruments, medical device components, and prosthetics.

- Packaging: for creating custom packaging solutions and prototypes.

- Aerospace: for manufacturing lightweight structural components and interior fittings.

- Signage and Displays: for crafting signage, lettering, and decorative elements.

2025 Market Trends of olymer and plastic laser cutting components

- The market for polymer and plastic laser cutting is expected to witness continued growth driven by advancements in laser technology, increasing demand for customized and complex components, and the growing adoption of additive manufacturing techniques.

- Trends such as sustainability and eco-friendliness are likely to influence material choices, with a preference for recyclable and biodegradable polymers.

- Additionally, the versatility and precision of polymer and plastic laser cutting make it an attractive solution for emerging industries and innovative applications, further driving market growth and expansion.

Reviews

There are no reviews yet.