Ceramics Micromachining:An Overview

Welcome to the art of Ceramics Micromachining meets the cutting-edge expertise of Welle, your premier Laser Micromachining facility. In this dynamic area, we redefine the boundaries of what’s achievable, unleashing a realm of possibilities for industries seeking unparalleled precision and customization.

Ceramics Micromachining encompasses a diverse range of techniques tailored specifically for the intricate manipulation of ceramic materials. From micro-milling to laser cutting, it’s a comprehensive toolbox designed to meet the most demanding requirements with finesse and accuracy.

Let’s delve deeper into the realm of Ceramics Micromachining:

What is the Ceramics Micromachining?

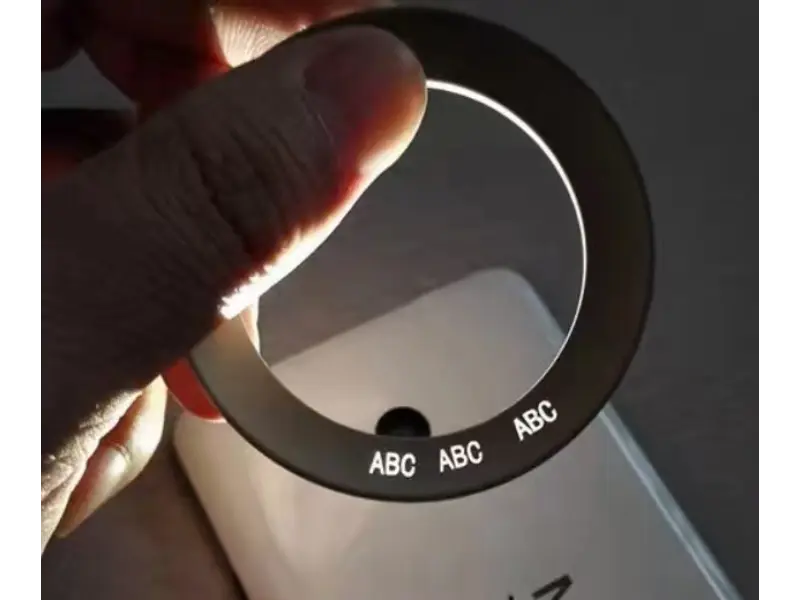

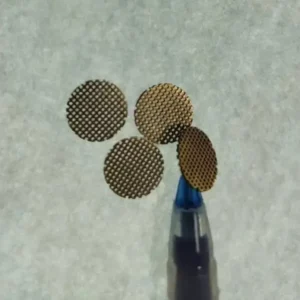

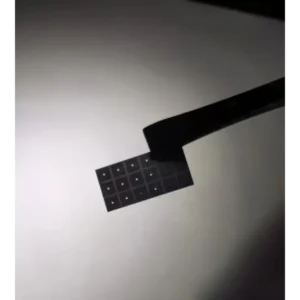

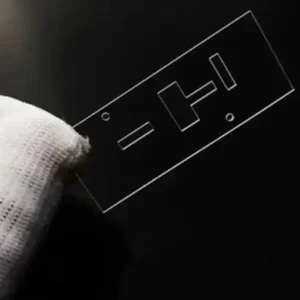

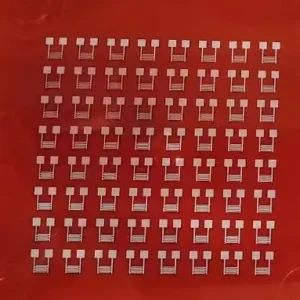

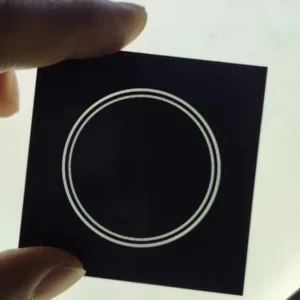

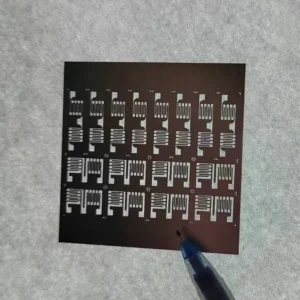

Ceramics Micromachining is the precise shaping and manipulation of ceramic materials at a microscale level. It involves intricate processes such as micro-milling and laser cutting, tailored to achieve the highest levels of precision and detail.

How do the Processing of Ceramics Micromachining?

Within Ceramics Micromachining, we employ a spectrum of techniques to suit diverse needs. From micro-milling, which involves the precise removal of ceramic material at the microscale, to laser cutting, where high-powered lasers are used to precisely cut through ceramic substrates, each process is meticulously chosen to ensure optimal results.

Where of the Ceramics Micromachining applications?

The applications of Ceramics Micromachining are vast and varied. From Semiconductor Processing and ceramic machining to the fabrication of intricate ceramic components for industries ranging from electronics to aerospace, the possibilities are limitless. Whether it’s the micro-fabrication of ceramics for additive manufacturing or the laser cutting of alumina ceramic plates for advanced applications, Ceramics Micromachining opens doors to innovation across industries.

What’s the Industries of Ceramics Micromachining components?

The future of Ceramics Micromachining is exceptionally bright. As industries continue to demand smaller, more intricate components with uncompromising precision, the need for advanced micromachining techniques will only grow. From medical devices to consumer electronics, Ceramics Micromachining will play a pivotal role in driving innovation and pushing the boundaries of what’s possible.

At Welleshaft, we are committed to leading the charge in Ceramics Micromachining. With our state-of-the-art facilities, experienced team, and unwavering dedication to excellence, we stand ready to partner with you on your journey towards precision and innovation. Together, let’s unlock the full potential of Ceramics Micromachining and redefine the future of manufacturing.

Reviews

There are no reviews yet.