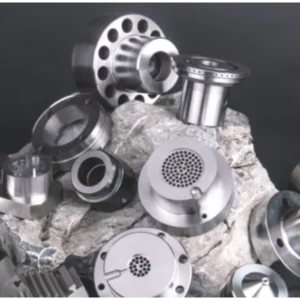

Ceramic Machining:An Overview

What is Ceramic Machining?

Ceramic machining refers to the process of shaping and finishing ceramic materials into precise components, it meet specific design and functional requirements. Due to the hardness and brittleness of ceramics, specialized machining techniques are necessary to achieve the desired dimensions and surface finishes.

Types of Ceramic Machining

1. Grinding

- Surface Grinding: Involves using a rotating abrasive wheel to remove material from the surface of the ceramic component, achieving a high level of precision and surface finish.

- Cylindrical Grinding: Used to shape the external surface of cylindrical ceramic parts, ensuring roundness and dimensional accuracy.

2. Drilling

- Ultrasonic Drilling: Uses high-frequency vibrations to drill precise holes in ceramic materials, minimizing the risk of cracking.

- Diamond Drilling: Employs diamond-tipped drill bits to penetrate hard ceramic surfaces, providing clean and accurate holes.

3. Milling

- CNC Milling: Computer Numerical Control (CNC) milling machines are used to perform complex cutting operations on ceramic materials, allowing for intricate shapes and precise dimensions.

- End Milling: Utilizes end mills to cut and shape the ceramic component, commonly used for creating slots, pockets, and profiles.

4. Laser Machining

- Laser Cutting: Uses high-energy laser beams to cut ceramic materials with extreme precision, ideal for intricate designs and delicate components.

- Laser Drilling: Provides accurate and clean holes in ceramic parts, suitable for applications requiring fine features.

5. Lapping and Polishing

- Lapping: Involves using a lapping plate and abrasive slurry to achieve a flat and smooth surface on the ceramic component.

- Polishing: Enhances the surface finish of ceramic parts, providing a mirror-like appearance and improving their functional performance.

Part Applications of Machined Ceramic Components

1. Electronics

- Insulators: Machined ceramic insulators are used in electronic devices to provide electrical insulation and thermal management.

- Substrates: Ceramic substrates are essential for mounting electronic circuits and components due to their excellent thermal and electrical properties.

2. Medical Devices

- Surgical Instruments: Precision-machined ceramic components are used in surgical instruments for their biocompatibility and resistance to wear and corrosion.

- Dental Implants: Ceramic dental implants offer high strength and aesthetic appeal, making them a preferred choice in dentistry.

3. Aerospace

- Thermal Shields: Machined ceramic thermal shields protect aerospace components from extreme temperatures and thermal stress.

- Sensor Components: Ceramic parts are used in sensors and instrumentation due to their stability and reliability under harsh conditions.

4. Automotive

- Brake Discs: Ceramic brake discs provide superior performance and longevity compared to traditional metal discs.

- Engine Components: Machined ceramic components are used in high-performance engines for their heat resistance and durability.

5. Industrial Machinery

- Bearings: Ceramic bearings offer high wear resistance and low friction, enhancing the efficiency and lifespan of industrial machinery.

- Seals and Valves: Precision-machined ceramic seals and valves are used in chemical and petrochemical industries for their chemical inertness and strength.

Conclusion

Ceramic machining is a critical process for creating high-precision components used in various advanced applications. By utilizing specialized techniques such as ceramic grinding, drilling, milling, laser machining, and lapping. Manufacturers can produce ceramic pieces that meet stringent design and performance criteria. These components find applications in electronics, medical devices, aerospace, automotive, and industrial machinery. It highlighting the versatility and importance of ceramic materials.

Reviews

There are no reviews yet.