Investment casting aluminum alloys:An Overview

Section 1: What is Aluminum Alloy Investment Casting?

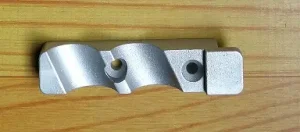

Aluminum investment casting is a manufacturing process that involves creating a wax model, coating it in ceramic material to form a mold, and then melting away the wax to pour molten aluminum into the mold. The result is a precise aluminum component with exceptional surface finish and intricate geometries.

1.1. Key Steps in the Aluminum Investment Casting Process

- Wax Pattern Creation: A replica of the desired part is crafted from wax.

- Assembly: Multiple wax patterns are attached to a central wax sprue, forming a tree structure.

- Ceramic Shell Formation: The wax assembly is dipped in ceramic slurry and coated with sand, creating a robust ceramic shell.

- Wax Removal: The shell is heated to remove the wax, leaving a hollow mold.

- Metal Pouring: Molten aluminum is poured into the mold.

- Cooling and Solidification: The metal cools and hardens.

- Shell Removal: The ceramic shell is broken away, revealing the cast component.

- Finishing: The part undergoes machining, heat treatment, and surface finishing as needed.

Section 2: Advantages of Aluminum Investment Casting

1. Superior Design Flexibility

Investment casting allows for complex geometries that are difficult to achieve with traditional methods. Thin walls, intricate internal features, and sharp edges are possible, making it ideal for sophisticated components.

2. Lightweight and Strong

Aluminum’s excellent strength-to-weight ratio makes it suitable for applications where weight reduction is critical, such as in aerospace and automotive industries.

3. Excellent Surface Finish

The process produces components with smooth surfaces and tight tolerances, minimizing the need for additional machining.

4. Material Versatility

Various aluminum alloys can be used, offering properties like corrosion resistance, thermal conductivity, and wear resistance.

5. Cost-Efficiency for Complex Parts

Although investment casting may have higher initial costs, its ability to produce near-net-shape parts reduces material waste and machining time, leading to overall cost savings.

Section 3:Aluminum Investment Casting vs. Other Casting Methods

Investment Casting vs. Sand Casting

- Precision: Investment casting offers tighter tolerances and smoother surfaces.

- Complexity: Investment casting excels in creating intricate parts, while sand casting is better for simpler geometries.

Investment Casting vs. Die Casting

- Material Options: Investment casting accommodates a broader range of alloys.

- Batch Sizes: Die casting is ideal for high-volume production, whereas investment casting suits medium to low quantities.

Section 4: FAQs About Aluminum Investment Casting

1. What Are the Heat Treatments Used in Aluminum Alloy Investment Casting?

- T5: Artificial aging after cooling from an elevated temperature shaping process to enhance strength.

- T6: Solution heat treatment followed by artificial aging, providing high strength and hardness.

- T7: Solution heat treatment followed by stabilization, used to increase resistance to stress corrosion and reduce susceptibility to cracking.

2. What is Post-Machining Manufacturing in Aluminum Alloy Investment Casting?

- CNC Machining: Precision cutting and shaping of the cast part to meet exact dimensions.

- Drilling and Tapping: Creating holes and threads in the cast part for assembly purposes.

- Surface Finishing: Techniques like polishing, anodizing, and coating to enhance the surface properties and appearance of the part.

3. What Are the Dimensions Accuracy and Roughness in Aluminum Alloy Investment Casting?

- Dimensional Accuracy: Typically within ±0.005 inches (±0.127 mm) per inch, making it ideal for precision components.

- Surface Roughness: Achievable finishes range from 63 to 125 microinches Ra (1.6 to 3.2 µm), providing smooth surfaces that often require minimal finishing.

4. What Are the Quality Measuring Methods for Aluminum Alloy Investment Cast Parts?

- Dimensional Inspection: Using precision measuring tools and coordinate measuring machines (CMM) to verify dimensions.

- Non-Destructive Testing (NDT): Techniques such as X-ray, ultrasonic testing, and dye penetrant inspection to detect internal and surface defects.

- Material Testing: Chemical analysis and mechanical testing to verify alloy composition and properties.

- Visual Inspection: Checking for surface defects and overall appearance.

5. What Are the Tool Costs for Aluminum Alloy Investment Casting?

- Pattern Creation: The initial creation of the wax pattern mold, which can be expensive but is offset by the ability to produce multiple parts.

- Die and Mold Fabrication: Investment in durable and precise molds, which can be reused for multiple casting cycles.

- Overall Cost: While initial tooling is high, the cost per part decreases significantly with higher production volumes.

6. What Are the Benefits of Aluminum Alloy Investment Casting?

- High Precision: Excellent dimensional accuracy and intricate detail.

- Versatility: Suitable for a wide range of applications and complex geometries.

- Material Efficiency: Minimal waste compared to other processes.

- Superior Surface Finish: Provides high-quality surface finishes that often require minimal post-processing.

7. What Are the Applications of Aluminum Alloy Investment Casting?

- Aerospace: Engine components, structural parts, and lightweight assemblies.

- Automotive: Engine parts, transmission components, and lightweight structural elements.

- Medical: Surgical instruments and implantable devices.

- Industrial: Pumps, valves, and machinery components.

- Consumer Goods: High-quality components for electronics and household appliances.

8. What Should Be Considered When Choosing Aluminum Alloy Investment Casting?

- Part Complexity: Ideal for intricate and complex designs.

- Material Requirements: Ensure the alloy used meets the application’s demands.

- Production Volume: Higher volumes can offset initial tooling costs.

- Lead Time: The process involves multiple steps, which can affect lead time.

Partner with Welleshaft for Superior Aluminum Investment Casting

For industries requiring precision, durability, and lightweight components, aluminum investment casting is the ultimate solution. Welleshaft stands as a trusted partner, offering unmatched expertise, advanced technology, and tailored solutions. Whether you need small batches or high-volume production, Welleshaft ensures quality, reliability, and value at every step.

Contact Welleshaft today to discover how their aluminum investment casting services can elevate your manufacturing processes and deliver superior components tailored to your needs.

Reviews

There are no reviews yet.