Precision Micromachining Services

From standard polymers to advanced engineering plastics like PEEK and acrylics, our expertise in laser micro machining accommodates various plastic materials. This flexibility is ideal for applications demanding intricate plastic components, with precision down to micrometers.

Learn MoreOur laser micro machining capabilities extend to a wide range of metals, including stainless steel, aluminum, titanium, and alloys. This versatility ensures precision in crafting components for diverse applications, with accuracy reaching up to micron-level dimensions.

Learn MoreLaser micro machining proves effective in shaping glass materials with precision. This is particularly valuable for industries requiring intricate glass components, such as optics and sensors, with precision reaching sub-micron levels.

With a focus on precision for the semiconductor industry, our laser micro machining processes cater to materials like silicon and gallium arsenide, ensuring accuracy in manufacturing electronic components, with tolerances within sub-micron ranges.

Precision in ceramic components is paramount, and our laser micro machining excels in materials such as alumina and zirconia. These ceramics find applications in electronics, medical devices, and more, with tolerances as tight as a few microns.

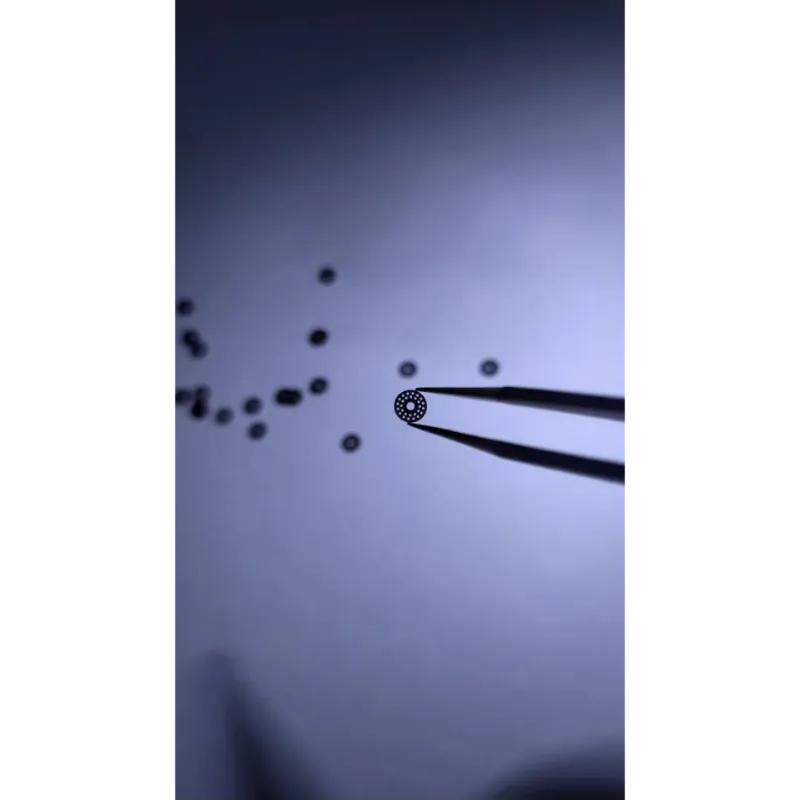

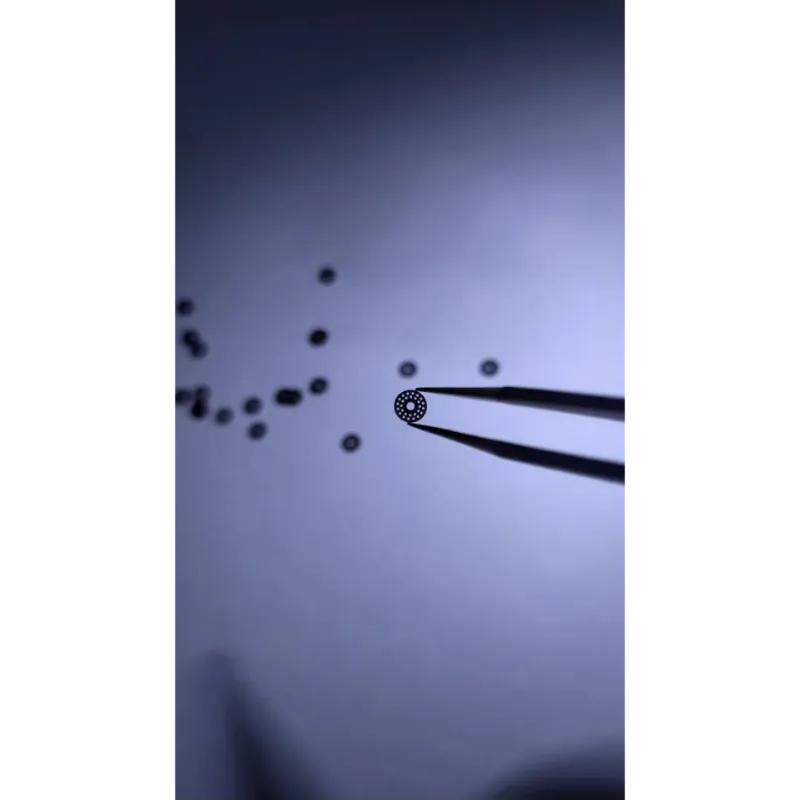

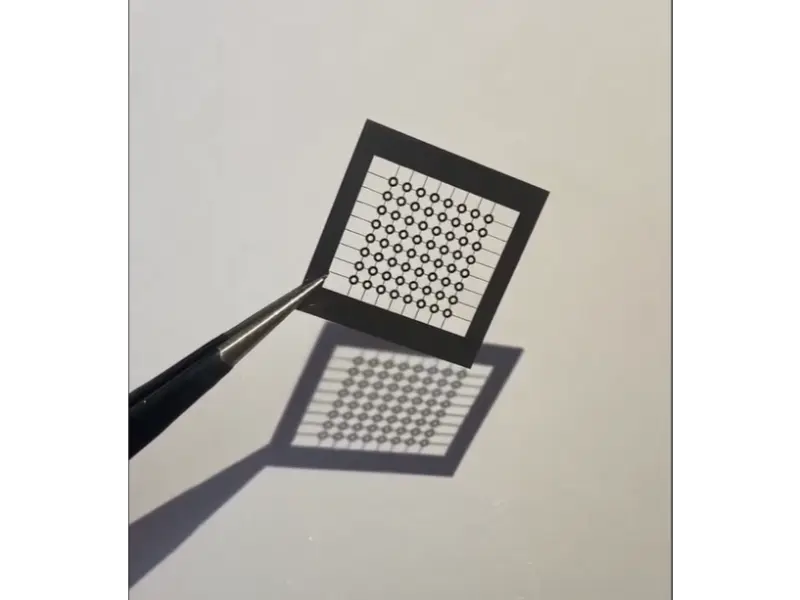

Learn MoreLaser micro machining is employed in crafting components from foams and porous materials. This is valuable in industries like aerospace and filtration, where intricate structures with precise micropores are necessary for optimal performance.

Learn MoreWe specialize in laser micro machining composites, blending materials like carbon fibers with polymers. This allows for the creation of lightweight yet durable components for aerospace and automotive applications, achieving precision at micron levels.

Laser micro machining is adept at working with flexible substrates such as polymers, films, and thin metal foils. This is particularly valuable in applications like flexible electronics, where precision at the micro and sub-micron level is essential.

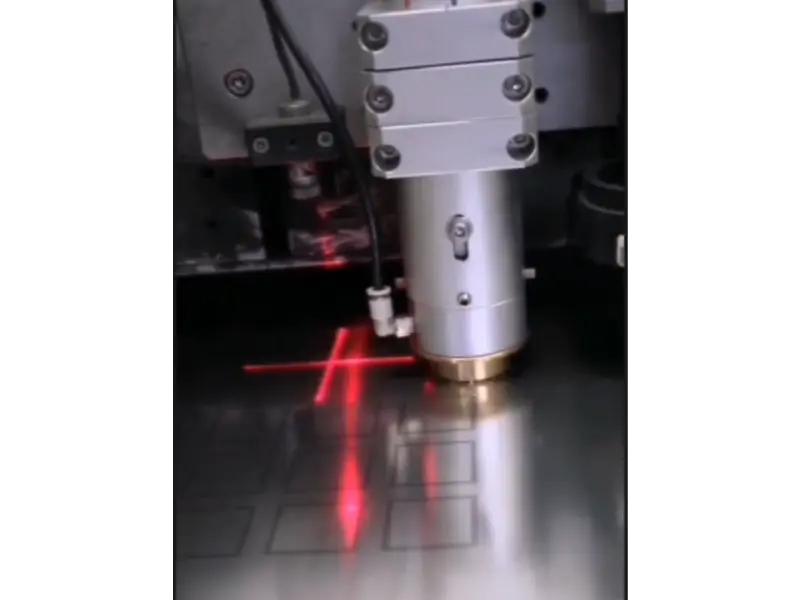

As a leading bespoke laser micro machining manufacturer, we take pride in offering a comprehensive range of customization options to meet the unique needs of our clients.Tailored for diverse applications, our laser-driven processes include:

As a specialist in Subcontract Laser Micromachining, we are more than a Laser Solution Provider – we are a reliable partner for Laser Micro Machining. Let us provide outstanding solutions for your projects and meet your custom Laser Micro Machining needs.

As a leading Laser Micro Machining manufacturer, we boast extensive industry experience, specializing in Laser Micromachining Services for numerous years. Our profound technical expertise ensures reliable solutions for our clients.

We employ state-of-the-art laser technology, including Femtosecond Laser Micromachining Applications, enabling 3D Laser Micro Milling for Polymer, Ceramic & Metal. This ensures efficient execution of processes such as Laser Micro Drilling, Laser Cutting, and Laser Engraving

Our experienced team is dedicated to various fields, from Laser Drilling and Laser Micro Drilling to Micro Laser Cutting, Laser Marking, and Laser Welding. Whether it’s nozzle drilling or calibrated micro holes, we provide expert technical support.

Anchored by Laser Drilling Contract Manufacturing, we implement Ultrashort Pulse Laser Micromachining for rigorous quality control. This commitment ensures the fulfillment of your custom Laser Micro Machining needs with precision.

As a Laser Micro Machining manufacturer, our holistic approach covers post-processing techniques that add value to the final products, and stringent quality inspections to guarantee precision and reliability.

Welcome to Welle Micromachining Services, where precision meets innovation. Our expertise in laser micro machining opens the door to a multitude of industries, revolutionizing the landscape of manufacturing. From electronics to medical devices, our cutting-edge solutions redefine what’s possible in micro-parts production. Explore the seamless fusion of technology and precision that sets Welle apart as a leader in micromachining for diverse industries.

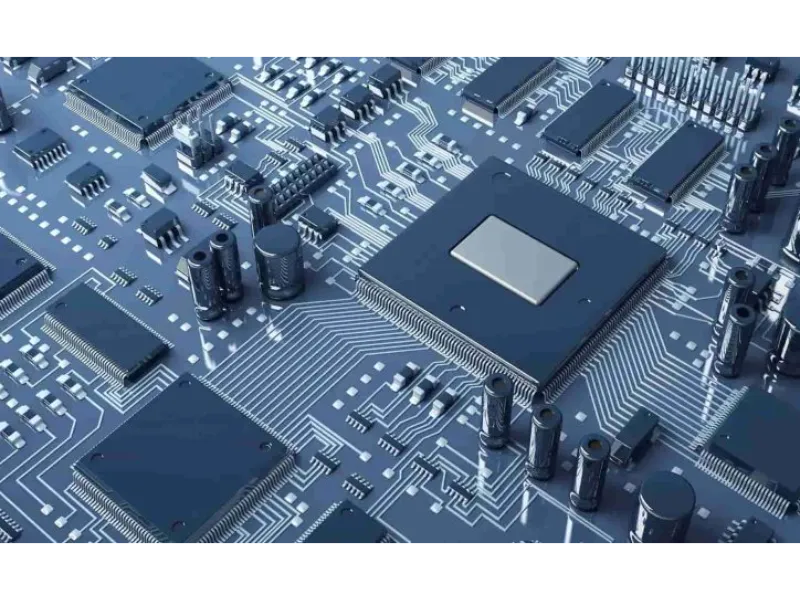

Micro parts play a crucial role in the miniaturization of electronic components. In applications such as microsensors, microcontrollers, and MEMS devices, precision-crafted micro-parts enable the development of compact and high-performance electronic systems.

Welle micro-parts find extensive applications in medical devices, contributing to the production of components for implants, diagnostic tools, and surgical instruments. Their small size and intricate designs enhance the functionality and precision of medical equipment.

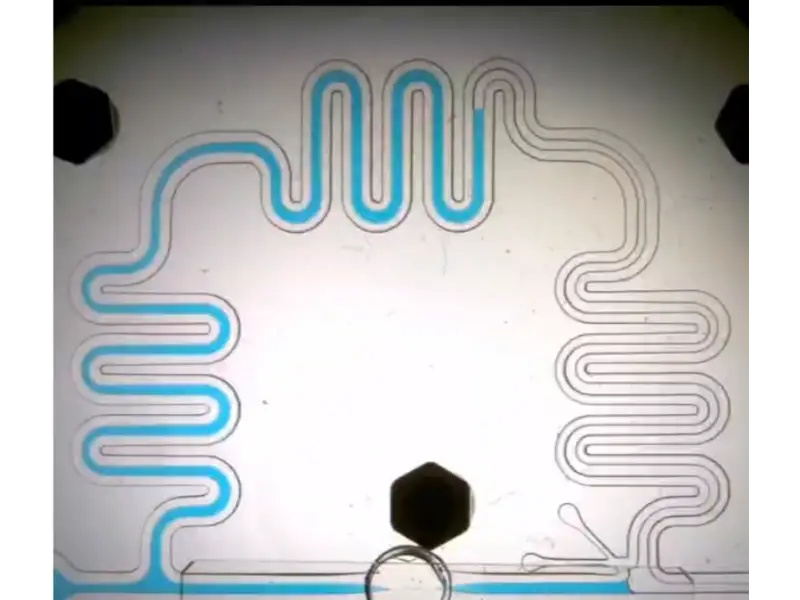

In the field of microfluidics, micro-parts are integral to the fabrication of lab-on-a-chip devices. These tiny components enable precise control of fluids at the microscale, facilitating advancements in diagnostics, chemical analysis, and biomedical research.

Laser micro parts play a key role in optics and photonics applications, contributing to the production of miniature optical components such as lenses, mirrors, and beam splitters. These components are vital for creating compact and high-performance optical systems in various industries.

In Laser Micro Machining, tolerances play a crucial role in achieving precision at the microscopic level. Tolerances can vary based on the specific requirements of the project, materials used, and the intricacy of the design. Typically, for micro machining processes like laser drilling, cutting, and engraving, tolerances range from a few micrometers to sub-micrometer levels. Achieving such tight tolerances ensures the production of high-quality components for various industries, including electronics, medical devices, and microfluidics.

At Welle, we specialize in tailoring our micro machining services to meet the unique tolerance demands of our clients, delivering exceptional precision and quality in every project.

Yes, our laser micro machining services are versatile, catering to both micro-part prototyping and large-scale production. This flexibility allows us to adapt to the varying needs of clients across different industries, ensuring seamless transitions from concept to mass production.