1.Bevel Gear Manufacturing Services – From Design to Production Bevel Gear Manufacturing Services are a cornerstone of modern industrial machinery, providing precise angular motion and torque transfer in automotive, aerospace, robotics, and heavy machinery applications. Selecting the right gear specifications and avoiding design errors is critical to ensure durability, performance, and operational efficiency. Companies that overlook these considerations risk costly production issues, premature wear, and downtime. At Welleshaft, we specialize in Bevel Gear Manufacturing Services, including custom bevel gear manufacturing, precision bevel gear production, and bevel gear inspection services, offering end-to-end solutions that optimize design, prototyping, machining, and quality inspection. 2.Understanding Bevel Gear Design Challenges Designing bevel gears is more complex […]

カテゴリーアーカイブ: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

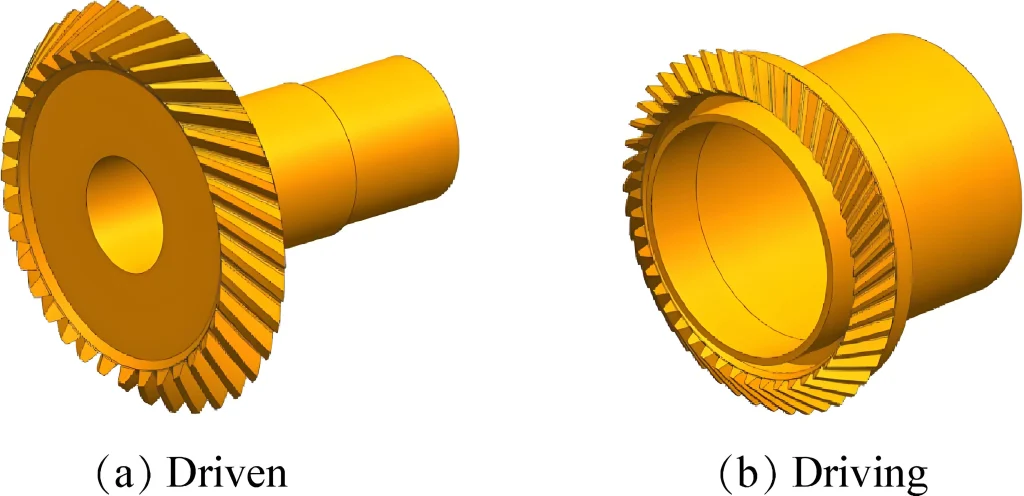

1.Bevel Gear Types – Choosing the Right Gear for Your Application When selecting from different Bevel Gear Types for industrial machinery, automotive systems, robotics, or heavy-duty applications, the wrong choice can lead to reduced efficiency, premature wear, and costly downtime. Many engineers and procurement teams struggle to determine whether spiral bevel gears, straight bevel gears, zerol bevel gears, or spiral miter gears will deliver the best performance for their unique operating conditions. As a trusted bevel gears manufacturing and bevel gear inspection service provider, Welleshaft offers expertise in custom bevel gear manufacturing, precision bevel gear production, and CNC bevel gear machining services to ensure every customer gets the right gear for their needs. we […]

1.Bevel Gears Custom for Industrial Applications In modern industrial operations, robotics, and heavy machinery, standard bevel gears often cannot meet unique performance requirements. Customers seeking custom bevel gear manufacturing, precision bevel gear production, and spiral bevel gear manufacturing frequently face challenges finding reliable solutions. Welleshaft offers comprehensive bevel gears manufacturing services, CNC bevel gear production, and industrial bevel gear inspection to ensure every bevel gear and pinion meets stringent specifications. From straight bevel gears to Zerol bevel gear and hypoid gear manufacturing, our custom-made bevel gears support heavy machinery, robotics systems, and specialized industrial equipment. Using advanced bevel gear machining services, gear measurement and inspection, and bevel gear quality inspection, Welleshaft delivers high-performance, durable custom bevel […]

1.Bevel Gear Inspection and Quality Assurance Before using any mechanical system, customers cannot guarantee the quality, durability, or performance of their bevel gears. That’s where bevel gear inspection service, custom bevel gear manufacturing, and precision bevel gear production become critical. At Welleshaft, we specialize in high-precision bevel gear inspection for industrial applications, spiral bevel gear manufacturing, straight bevel gear manufacturing, and CNC bevel gear production. Our professional bevel gear quality inspection and gear metrology services ensure that every bevel gear and pinion meets rigorous industrial standards. By combining advanced bevel gear machining services, conical gear inspection service, and thorough bevel gear testing services for durability and performance, we help clients avoid operational failures, reduce […]

1.High-Precision Bevel Gears for Critical Applications Customers seeking Precision Bevel Gear Manufacturing Services often require components for critical applications, such as automotive drive systems, robotics, and heavy machinery, where tight tolerances and reliable performance are essential. At Welleshaft, we specialize in bevel gears manufacturing, custom bevel gear manufacturing, precision bevel gear production, and bevel gear inspection service, ensuring every component meets stringent specifications. Understanding gear production, machining, inspection, and assembly processes is crucial to guarantee smooth operation, high efficiency, and extended lifespan in demanding industrial environments. 2.What is Precision Bevel Gear Manufacturing? Precision bevel gear manufacturing refers to producing high-quality bevel gears with exacting tolerances, optimized tooth profiles, and smooth surface finishes. The process […]

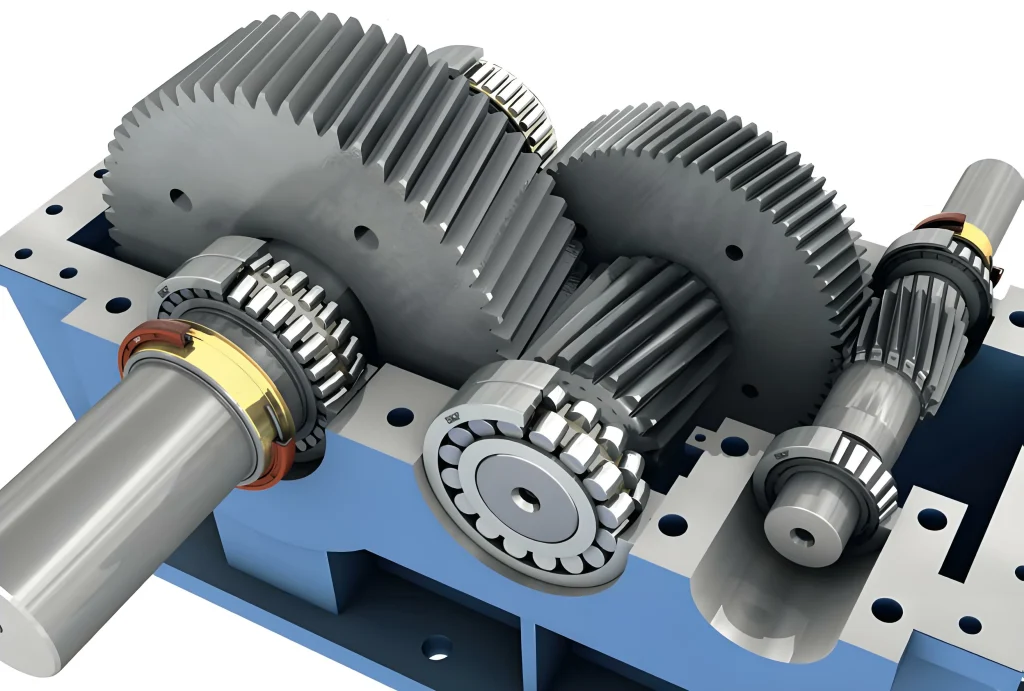

1.Understanding Bevel Gears Bevel gears are critical components for transmitting motion between intersecting shafts, often at right angles. Variants include straight bevel gears, spiral bevel gears, Zerol (zero) bevel gears, and hypoid gears, each with unique torque and speed characteristics. Proper bevel gears manufacturing ensures smooth operation and long lifespan. Welleshaft specializes in precision bevel gear production, custom bevel gear manufacturing, and bevel gear inspection services. Learn more in our Bevel Gears Guide, which explores production, inspection, and assembly processes critical for performance, efficiency, and reliability across industries from industrial machinery to robotics and marine applications. 2.Bevel Gear Manufacturing Process (1)How Bevel Gears Are Manufactured – From Design to Production […]

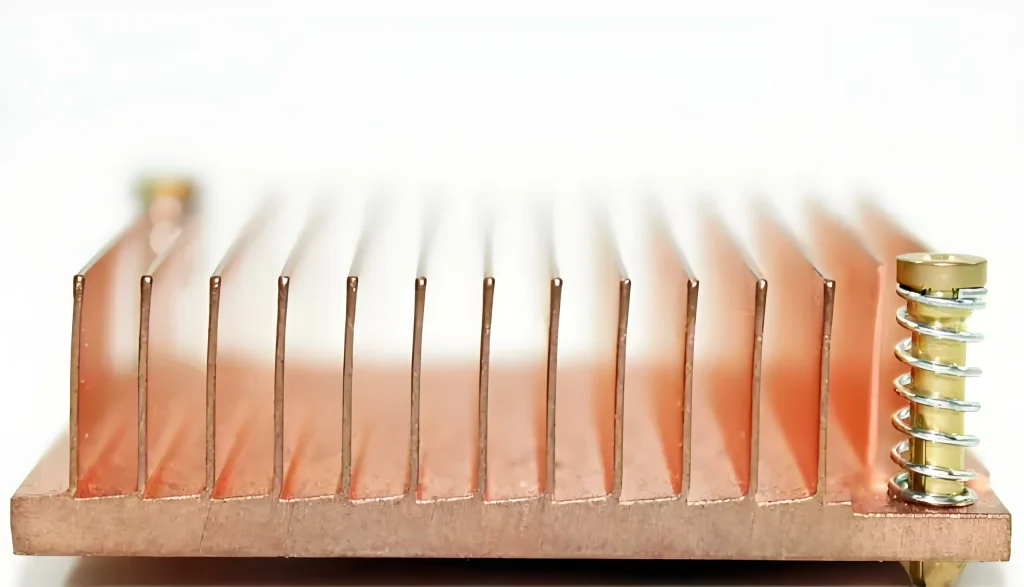

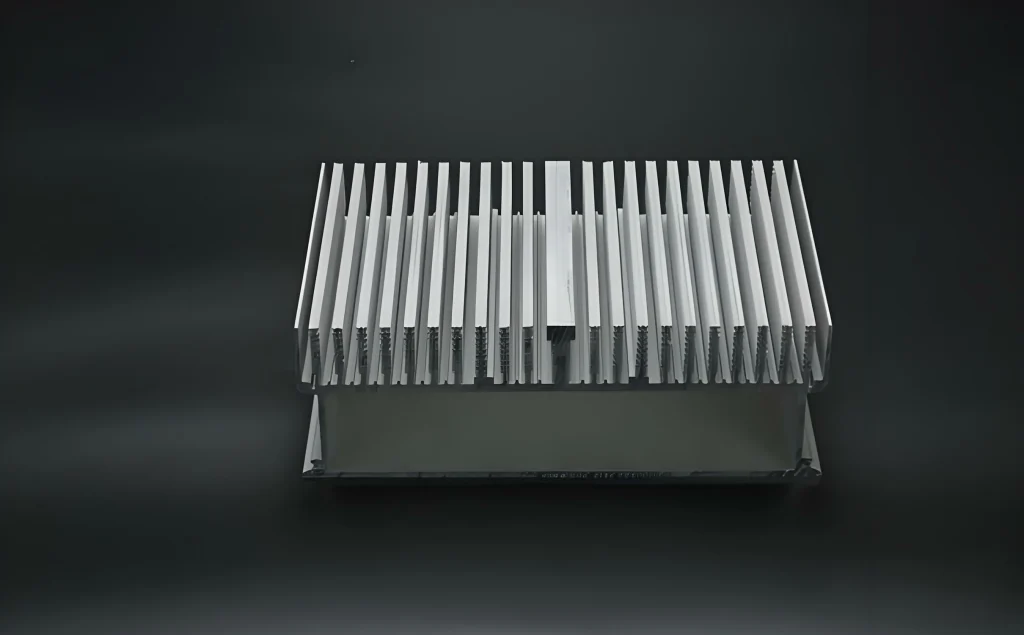

1.Regional Aluminum Heat Sink Inspection Services: Ensuring Quality and Reliability Aluminum heat sinks are vital in modern electronics, industrial machinery, and thermal management applications. Selecting the right aluminum heat sink inspection service is critical for ensuring device longevity, performance, and compliance with industry standards. Companies increasingly demand heat sink quality inspection and aluminum heat sink testing service solutions from providers who can deliver reliable results with fast turnaround. Understanding local inspection capabilities, service standards, and quality assurance processes is essential for operational efficiency and selecting reliable Regional Aluminum Heat Sink Inspection Services. Whether you are searching for aluminum heat sink inspection service near me or evaluating regional aluminum heatsink inspection providers, this guide […]

1.Industry Standards for Aluminum Heat Sink Quality Inspection: Ensuring Compliance and Performance In modern electronics and industrial applications, aluminum heat sinks are critical components that manage thermal energy and ensure device longevity. Selecting and producing heat sinks without adhering to industry standards for aluminum heat sink quality inspection can result in overheating, device failure, and costly recalls. Many companies face confusion when evaluating heat sink quality inspection requirements, particularly regarding thermal performance and mechanical standards. Understanding these regulations and implementing comprehensive aluminum heat sink testingservices is essential to safeguard performance, ensure safety, and protect ROI. This article provides an in-depth look at the standards, processes, and best practices for compliant heat sink […]

1.Why Aluminum Heat Sink QC Matters In modern electronics manufacturing, aluminum heat sink inspection is a critical step to ensure optimal thermal performance, reliability, and compliance with industry standards. A single poorly performing heat sink can compromise the efficiency of CPUs, GPUs, power supplies, and other high-performance electronics. Choosing the Right Aluminum Heat Sink QC Service enables manufacturers to detect defects such as warping, poor surface finish, dimensional inaccuracies, and thermal conductivity issues early, saving time, reducing costs, and ensuring consistent product quality. Choosing the right aluminum heatsink QC service can be challenging due to differences in inspection accuracy, turnaround time, and cost. This guide explores the process in depth and […]

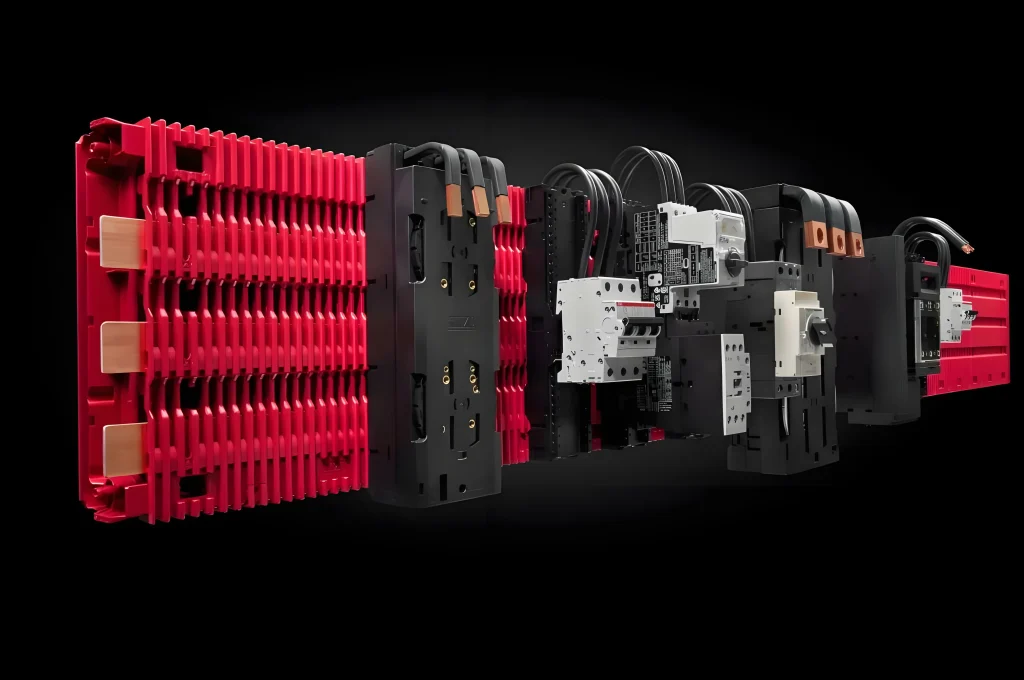

1.Busbar Product Issues: Common Problems and Prevention Strategies Busbar Product Issues are critical considerations in modern electrical systems, as busbar products ensure efficient power distribution and safe operation. From copper busbar and aluminum busbar to insulated busbar and busbar trunking, every element in a busbar system must function flawlessly. However, busbar products often encounter issues such as overheating, corrosion, mechanical wear, and poor electrical connectivity. In this article, we explore the most common Busbar Product Issues, how to identify defects, and effective preventive maintenance strategies. Whether you’re involved in busbar manufacturing, using busbar components in industrial setups, or managing electrical busbar systems, understanding these issues is key to extending product […]