What Is the Basic Theory Behind Threaded Fasteners in Fastener Manufacturing? In fastener manufacturing, threaded fasteners in fastener manufacturing play a critical role by turning rotational force into axial clamping force that securely holds parts together. When a bolt or screw is tightened, its threads engage with a nut or internal thread and pull the connected components firmly into place. This principle sits at the core of almost every fastener manufacturing company, from large manufacturing factories to local fastener manufacturers near me. In practice, a threaded fastener behaves much like a stretched spring. As you tighten it, the threads pull the shaft away from the head, causing the fastener to […]

カテゴリーアーカイブ: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

How Are Screws Manufactured? How Are Screws Made from Raw Material to Finished Product? The journey of making screws starts with raw materials, typically steel or stainless steel, which are melted, alloyed, and processed into the desired shape. The process of how screws are manufactured begins with the raw material, which is then cut, heated, and shaped through various techniques like threading and coating. After the screw takes shape, it undergoes strict quality checks to ensure precision, durability, and reliability. Manufacturing processes can vary based on the screw type, such as machine screws, wood screws, or specialty screws for industrial uses, each tailored for a specific application. What Are the […]

What Are Custom Screws and How Can They Enhance Your Products? What Are Screws and How Do They Work? Screws are essential fasteners found in nearly every industry, from construction to electronics. At their core, screws are designed to hold objects together by turning them into materials like wood, metal, or plastic. They work by using threads to create a strong, secure hold, effectively applying pressure to bind materials together. As a Custom Screw Manufacturer, we specialize in creating precision fasteners tailored to your specific needs, ensuring the highest quality and reliability for every application. Screws come in a vast range of shapes, sizes, and designs to suit different applications. […]

Which Stainless Steel Fasteners Are Best for Industrial Projects? What Are the Specifications of Stainless Steel Fasteners? When selecting stainless steel fasteners, understanding their specifications is crucial for reliable performance in industrial, construction, or mechanical projects. Specifications include material composition, bolt grades, tensile strength, hardness, corrosion resistance, and compliance with international standards like ISO, DIN, ASTM, and ASME. Stainless steel nut bolt combinations, such as 304 for mild environments and 316 for marine or chemical settings, ensure proper load distribution. Consulting grade charts helps reduce maintenance costs, prevent failures, and enhance safety across industrial applications. Choosing the right fasteners ensures long-term reliability. Stainless Steel Fasteners Specifications Specification Details Fastener Standards IS, […]

Are High-Tensile and Stainless Steel Bolts the Key to Safer, More Reliable Industrial Projects? Could High Tensile Steel and High Tensile Strength Bolts Solve Your Heavy-Duty Fastening Needs? For fasteners and fixings, High-Tensile and Stainless Steel Fasteners deliver proven strength and reliability. In construction, automotive, and heavy machinery, high tensile bolts such as grade 8.8 and 12.9 handle extreme stress without bending or failure. Manufacturers use alloy steel and heat treatment to boost durability and performance. These hard steel fasteners keep equipment safe, reduce downtime, cut maintenance costs, and meet ISO and DIN standards—making them a smart, dependable choice for engineers and procurement teams. What Makes High Tensile Stainless Steel […]

What Are the Key Types, Grades, and Applications of Stainless Steel Nuts, Bolts, and Fasteners for Reliable Industrial Assembly? What Are the Main Types of Stainless Steel Nuts, Bolts, and Fasteners? Stainless steel fasteners are the backbone of durable industrial assembly. From stainless steel nuts and stainless steel nut bolts to stainless steel bolts nuts and ss nuts and bolts, These Stainless Steel Nuts Bolts And Washers ensure that your projects stay secure under stress. Different designs serve different functions: hex nuts, acorn nuts, barrel nuts, jack nuts, and wing nuts all have specific applications. Choosing the right type can save time during assembly and reduce maintenance costs, especially in industries like petrochemical, […]

Stainless Steel Nuts and Bolts: Grades, Standards, and Sourcing Guide What Are the Main Stainless Steel Material Grades for Nuts and Bolts? SS Nuts And Bolts come in various grades, each with unique characteristics, making it essential to choose the right material for durability and performance. The most common ones include 316, 410, 304 and 18-8 stainless steel. 316 Stainless Steel: 316 stainless steel uses a mix of about 16–18% chromium, 10–14% nickel, and a touch of molybdenum, which gives it noticeably better corrosion resistance than 304 or standard 18-8 stainless. That extra protection is why 316 is the go-to choice for harsh, wet, or coastal environments—salt in the air […]

Stainless Steel Fasteners: Types, Grades, and Uses What Are Stainless Steel Fasteners and Their Types? When you’re building or fixing anything—from furniture to outdoor projects to boats—stainless steel fasteners (or ss fasteners) are usually the safest bet. They’re tough, resist rust extremely well, and come in all kinds of options like bolts, nuts, washers, studs, and specialty screws. At the end of the day, stainless steel fastners are essentially low-carbon steel with at least 10% chromium added, and it’s this chromium that provides the corrosion resistance everyone relies on. That’s why grades like 304 (general use) and 316 (marine use) are so popular. For harsher environments such as marine work, […]

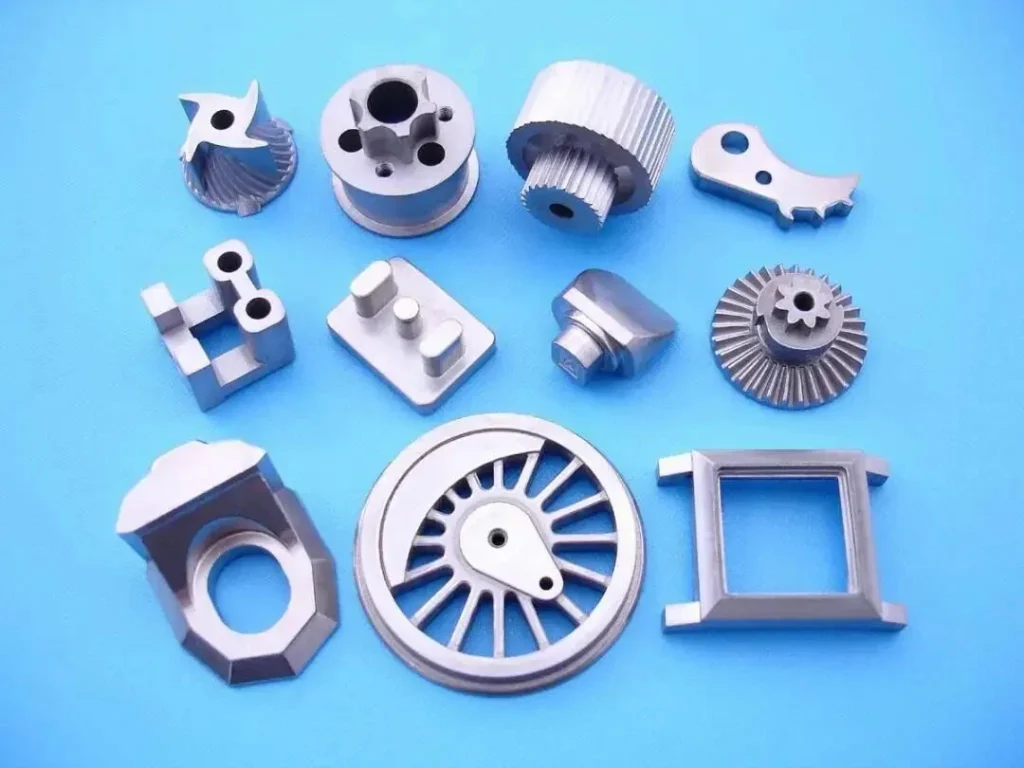

Powder Injection Molding (PIM) for Precision Metal Parts What Is Powder Injection Molding and How Does It Work? Powder Injection Molding (PIM)—also known as powder injection moulding—is essentially the metal or ceramic version of plastic injection molding. Instead of using polymer pellets, the process uses a mixture of fine metal powder + binder, creating an injectable feedstock that can be molded into complex shapes. The workflow is straightforward but highly engineered: Feedstock compounding – Metal powder and polymer binders are mixed to form injection molding powder. Injection molding – The feedstock is injected into a mold using a powder molding machine or metal injection molding machine. Debinding – The binder is removed through […]

The 8 Most Common Questions about metal injection molding – Asked and Answered How does metal injection molding compare to other manufacturing methods? Metal injection molding (MIM) combines the design freedom of plastic injection molding with the strength of metals, making it perfect for high-precision parts that are tough to produce with CNC machining or die casting. It excels at producing complex, net-shape components—even sub-gram parts that fit in your palm. MIM delivers intricate shapes with strong mechanical properties and consistent quality at high volumes, while simpler parts remain cheaper with press-sinter, turning, or stamping. For businesses aiming to cut waste, boost efficiency, and reliably make precision components, MIM is […]