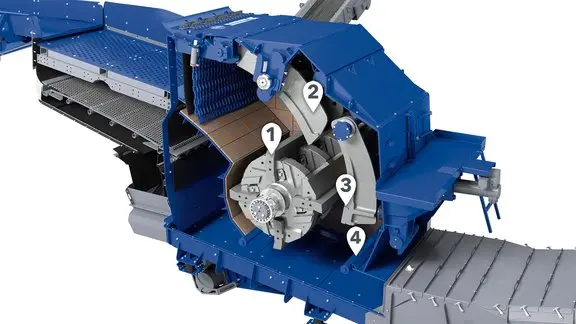

Impacting Blow Bars: Durable Crusher Parts for Effective Size Reduction Section 1:Introduction In the realm of material processing, efficient size reduction is paramount. Impact crushers, with their powerful blows, play a crucial role in achieving this goal. At the heart of these machines lie impacting blow bars, the workhorses that deliver the crushing force. These robust components are subjected to immense stress and wear and tear, making their durability and performance critical for optimal crushing operations. Section 2:Understanding Impacting Blow Bars Impacting blow bars, also known as crusher hammers or impact plates, are integral components of impact crushers. These machines utilize the principle of kinetic energy to break down materials. […]

カテゴリーアーカイブ: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

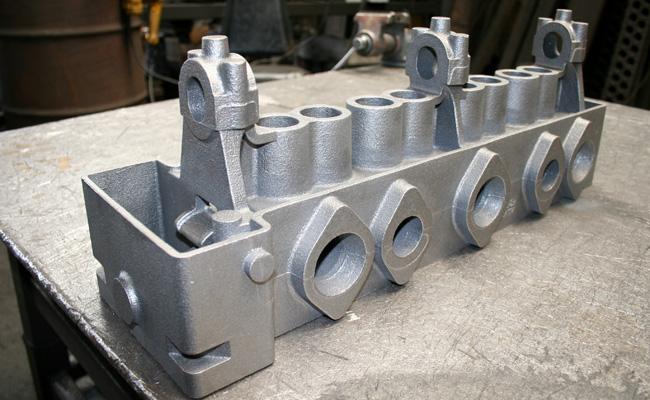

Section 1:Introduction In metal casting, innovation drives advancements in manufacturing processes. One such groundbreaking technology leverages additive manufacturing to create intricate and precise molds for superior castings. This article explores the advantages, applications, and the role of trusted global suppliers like Welleshaft in shaping the future of this transformative technology. Section 2:Understanding 3D Printed Sand Molding Traditional sand casting involves creating molds using handcrafting techniques or pattern-based methods, which can be time-consuming and prone to inaccuracies. 3D printed sand molding, however, revolutionizes this process by utilizing 3D printing technology to directly fabricate sand molds from digital designs. This approach offers several key advantages: 2.1 Enhanced Precision and Complexity: 3D printing […]

Introduction In the realm of medical technology, precision isn’t just a luxury; it’s a necessity. The efficacy of medical devices, from life-saving implants to delicate surgical instruments, hinges on the accuracy and reliability of their components. This is where medical CNC machining steps in, playing a pivotal role in bringing cutting-edge medical advancements to fruition. Among the various machining techniques, milling, turning, and EDM (Electrical Discharge Machining) stand out as essential processes for manufacturing high-quality, complex medical components. This article will delve into the applications, processes, and importance of these techniques, and why choosing the right partner for these services is critical. Section 1: The Significance of Medical CNC Machining Medical CNC machining is a manufacturing […]

Durable Rubber Mill Liners | High-Performance Solutions for Mining & Milling Operations In the demanding industries of mining and milling, where durability and performance are critical, Durable Rubber Mill Liners have emerged as an indispensable solution. These liners deliver exceptional wear resistance, reduce operational downtime, and offer long-term cost-effectiveness—making them a superior alternative to traditional steel or composite materials. Welleshaft, a trusted global supplier and contract manufacturer, specializes in Durable Rubber Mill Liners engineered to meet the specific demands of various industrial applications, ensuring reliable performance and extended service life. Understanding Rubber Mill Liners Rubber mill liners are protective layers installed inside grinding mills to protect the equipment and enhance […]

Advanced Rubber Mill Liner for Enhanced Efficiency | Durable & High-Performance Solutions In the world of heavy industries like mining, cement production, and other grinding applications, equipment efficiency and durability are paramount. One crucial component that plays a significant role in milling operations is the mill liner. It protects the mill’s inner surface, ensures optimal grinding, and minimizes downtime due to maintenance. Among various types, the Advanced Rubber Mill Liner has gained popularity for its exceptional performance, durability, and cost-effectiveness. This article will explore the benefits of advanced rubber mill liners for enhanced efficiency and how Welleshaft provides high-quality, reliable solutions for industries worldwide. The Importance of Mill Liners in […]

What is the Difference Between A380 and ADC12 Aluminum? | Alloy Comparison and Applications The differences between A380 and ADC12 aluminum alloys primarily lie in their composition, mechanical properties, and suitability for different applications. Both are commonly used in die-casting processes, particularly in automotive and electronics, but they have unique characteristics that make them suitable for different types of products. 1. Composition A380 Aluminum: Main Elements:Primarily composed of Aluminum (Al), Silicon (Si), and Copper (Cu). Silicon Content:Around 7-9%, which provides good fluidity during casting, making it ideal for intricate shapes. Copper Content:Higher than ADC12, typically 5-3.5%, which enhances strength and hardness. ADC12 Aluminum: Main Elements:Contains a similar composition to A380, with Aluminum […]

What is ADC12 Aluminum Used For? | Applications and Benefits of ADC12 Alloy ADC12 aluminum is a versatile and widely used alloy in various industries due to its excellent castability, strength, and corrosion resistance. Below are some of the primary applications of ADC12 aluminum: 1. Automotive Industry Engine Components: Manufacturers commonly use ADC12 to make automotive engine components such as cylinder heads, engine blocks, and intake manifolds. Its ability to withstand high temperatures and excellent fluidity during casting make it ideal for these applications. Transmission Housings: Producers rely on ADC12 for manufacturing transmission housings and other automotive parts that require high strength and wear resistance. Wheels and Alloy Parts: ADC12 […]

What is ADC12 Aluminum Equivalent To? | Comprehensive Alloy Comparison Guide Section 1: ADC12 Aluminum Specification and Standards ADC12 aluminum is a high-quality die-casting alloy commonly used in manufacturing. Its equivalents in other countries or regions depend on the composition and mechanical properties required for specific applications. Below are some international equivalents to ADC12 aluminum, answering the question: What is ADC12 Aluminum Equivalent?” 1. A383 (USA) A383, as per the ASTM B85 standard, is considered the closest equivalent to ADC12. Both alloys share similar compositions, including high silicon content for excellent castability and corrosion resistance. 2. LM24 (UK) LM24, under the BS 1490 standard, is widely used in the UK […]

Lost Foam Casting vs Investment Casting | Key Differences & Applications Casting is a key process in manufacturing that involves shaping molten metal into a desired shape using a mold. Two of the most popular casting methods used by manufacturers are Lost Foam Casting and Investment Casting. Both techniques have their unique advantages, disadvantages, and applications depending on the materials and the requirements of the final product. In this article, we will explore Lost Foam Casting vs Investment Casting, their differences, processes, advantages, and common uses. We will also discuss how Welleshaft, a trusted global supplier and contract manufacturer, can assist you with these casting solutions. What is Lost Foam Casting? […]

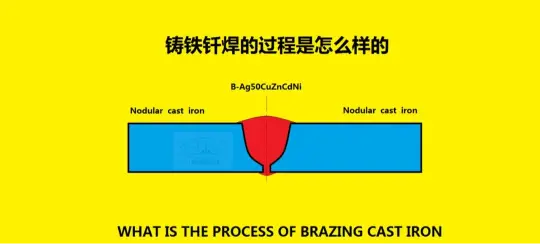

Brazing Cast Iron | Reliable Techniques & Expert Solutions for Strong Metal Bonds Brazing cast iron is a specialized process that combines expertise and precision to achieve high-quality, durable metal bonds. In this guide, we’ll explore reliable brazing techniques for cast iron and discuss how Welleshaft, a trusted global supplier and contract manufacturer, can support your brazing needs. Whether you’re working with intricate cast iron blocks, using TIG brazing, or employing different fuel sources, this article will cover essential aspects of the brazing process. What is Brazing Cast Iron? Brazing cast iron is a joining process where a filler metal is melted and applied between two cast iron parts to […]