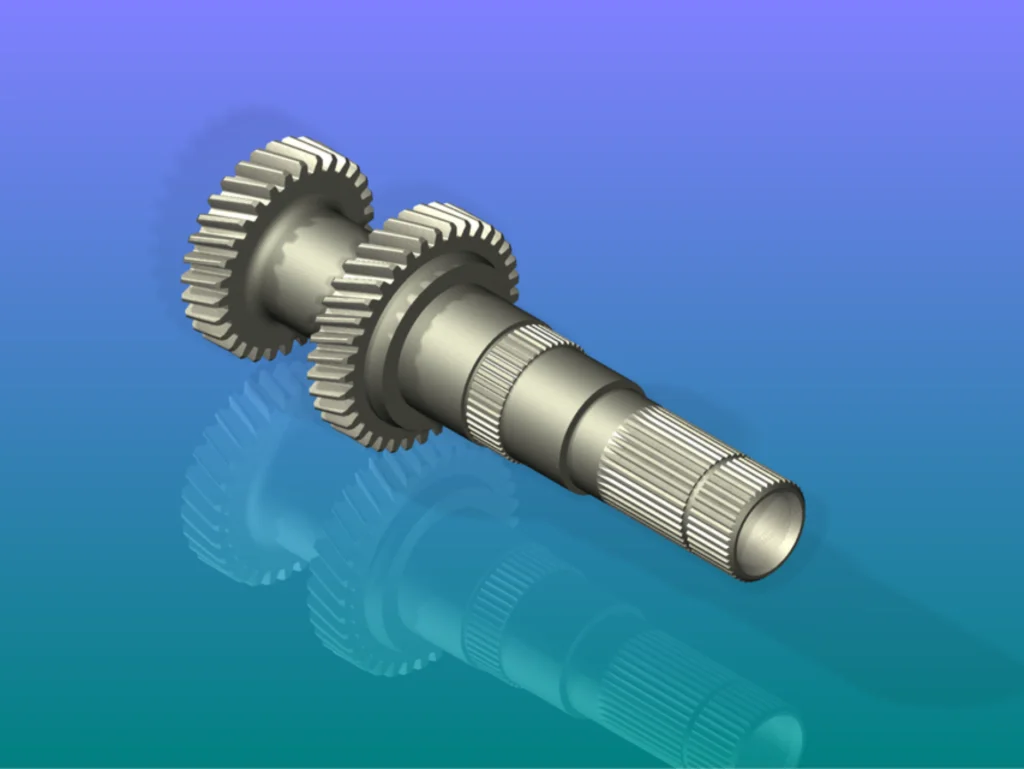

Precision Engineered Hollow Drive Shafts | Improve Performance & Fuel Economy Hollow drive shafts represent a pivotal advancement in drivetrain technology, offering a superior alternative to traditional solid drive shafts. Through precision engineering and advanced materials, these shafts deliver enhanced performance, improved fuel economy, and increased reliability. This article explores the design, benefits, applications, and manufacturing of precision engineered hollow drive shafts, showcasing why they’re the preferred choice for modern vehicles and industrial equipment. It concludes with a strong recommendation for Welleshaft as a trusted global supplier and contract manufacturer. The Evolution of Drive Shafts: From Solid to Hollow The drive shaft plays a crucial role in transmitting torque from […]

カテゴリーアーカイブ: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

Hollow Linear Shaft: Precision Guide Shafts for Linear Motion Introduction In the realm of linear motion, precision, efficiency, and weight are crucial. Hollow Linear Shaft solutions offer an ideal balance of these attributes. Widely used in robotics, automation, 3D printing, and more, they enable smooth and accurate linear movement. This article explores the advantages, applications, and selection criteria for hollow linear shafts, while highlighting Welleshaft as a trusted global supplier and contract manufacturer in this specialized field. What is a Hollow Linear Shaft? A hollow linear shaft is a precision-engineered component designed to guide and support linear motion. Unlike solid shafts, hollow shafts feature a cylindrical bore that runs through […]

Tubular Shafts for Drive Systems, Robotics & More Tubular shafts, also known as hollow shafts or cannulated shafts, are a versatile and increasingly popular engineering component used in a wide range of applications. From high-performance drive systems and precision robotics to specialized machinery and innovative medical devices, the unique properties of tubular shafts offer significant advantages over their solid counterparts. This article explores the benefits of tubular shafts, their diverse applications, material considerations, and why they are becoming an essential element in modern engineering design. What are Tubular Shafts? In its simplest form, a tubular shaft is a cylindrical component with a hollow core. This fundamental design difference from a […]

Toyota Diffusion Processing (TD): The Advanced Carbide Coating Process In the world of materials science and surface engineering, achieving exceptional wear resistance and hardness is essential. TD Processing Advanced Carbide Coating Process, also known as Thermal Diffusion Coating, is a highly effective method for forming extremely hard carbide layers on steel surfaces. Originally developed by Toyota, this process delivers superior performance in demanding environments, significantly extending the lifespan and efficiency of tools, dies, and other critical components. In this comprehensive guide, we’ll explore the principles behind TD Processing, its benefits, key applications, and how it compares to other surface treatment methods. Section 1 What is Toyota Diffusion Processing (TD Processing)? TD […]

Nitriding Methods: Gas, Salt Bath, & Plasma – Advanced Steel Treatment Nitriding is a heat treatment process that enhances surface hardness, wear resistance, and fatigue strength of steel parts by diffusing nitrogen into the metal at elevated temperatures. This creates a hard, wear-resistant case layer without the need for quenching, which helps minimize distortion—making it ideal for precision components. In this comprehensive guide, we’ll explore key Nitriding Methods: Salt Bath, Plasma, and gas nitriding—examining their principles, benefits, limitations, and applications across various industries. Section 1 Why Nitriding? The Benefits of Nitrogen Enrichment Before diving into the specifics of each method, it’s important to understand the benefits that nitriding offers: 1.1 Increased […]

Salt Bath Nitriding Services: Improve Metal Hardness & Wear Resistance Section 1 Introduction In today’s demanding manufacturing landscape, the performance and longevity of metal components are paramount. Achieving superior surface properties, like enhanced hardness and wear resistance, is crucial for extending the lifespan of critical parts and ensuring optimal functionality. One effective solution for achieving these results is salt bath nitriding, a thermochemical process that significantly improves the characteristics of metal surfaces. At [Your Company or “a leading provider”], we offer expert salt bath nitriding services designed to meet a wide range of industrial needs, ensuring that your components can withstand even the harshest operating environments. In this comprehensive guide, we’ll delve into the […]

MIM Gear Process: Achieve Complex Gear Designs with Metal Injection Molding Section 1 Introduction Metal Injection Molding (MIM) has emerged as a transformative manufacturing process, particularly for creating intricate and high-performance components like gears. The MIM Gear Process combines the design flexibility of injection molding with the material properties of powder metallurgy, allowing for the production of complex gear geometries with exceptional precision and consistency. This article will delve into the intricacies of the MIM gear process, explore its advantages, discuss the materials used, and introduce Welleshaft as a reliable partner for MIM gear production. We will also examine the many uses of this technology. Section 2 Understanding the MIM Gear […]

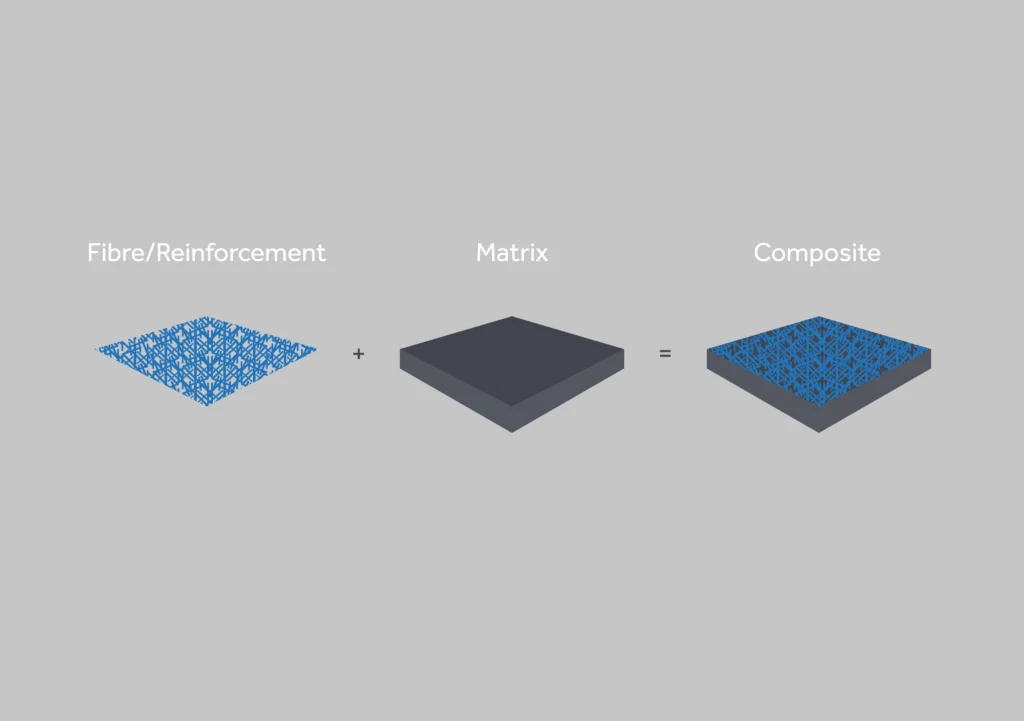

Resin Matrix Composite Material Processing: Layup, Curing & Advanced Manufacturing Section 1 Introduction Resin matrix composites have revolutionized industries ranging from aerospace and automotive to sporting goods and medical devices. Their exceptional strength-to-weight ratio, design flexibility, and corrosion resistance have made them indispensable in modern manufacturing. This article delves into the intricate world of Resin Matrix Composite Material Processing, focusing on the fundamental techniques of layup and curing, exploring advanced manufacturing methods, and highlighting the diverse applications of these remarkable materials. We’ll also address some of the challenges associated with their production and introduce how Welleshaft is meeting the ever-evolving demands of this field through cutting-edge Resin Matrix Composite Material Processing […]

Reliable Ceramic Component Grinding and Processing Services | Solving Your Machining Challenges Section 1 Introduction In today’s advanced engineering landscape, ceramic materials are increasingly vital for their exceptional properties: high hardness, thermal resistance, chemical inertness, and electrical insulation. However, these very attributes make them notoriously difficult to machine. Ceramic component grinding and precision processing demand specialized expertise, cutting-edge equipment, and a deep understanding of material behavior. This article explores the challenges associated with ceramic machining and introduces a trusted solution: Welleshaft, a global leader in reliable ceramic component manufacturing. Whether you require tight tolerances, complex geometries, or customized material processing, Welleshaft is your go-to partner for overcoming your most demanding machining challenges […]

Enhance Semiconductor Production with High-Performance Ceramic Equipment Parts The semiconductor industry is at the heart of modern technology, powering everything from smartphones to advanced medical devices. As demand for microchips continues to soar, manufacturers are constantly seeking ways to improve production efficiency, precision, and yield. A critical, often overlooked, component in this quest lies in the high-performance materials used in semiconductor manufacturing equipment. Among these, ceramic parts have emerged as indispensable elements due to their unique properties and ability to withstand the harsh conditions of semiconductor fabrication. By choosing to enhance production with ceramic equipment parts, manufacturers can achieve greater durability, thermal stability, and process reliability. This article will explore […]