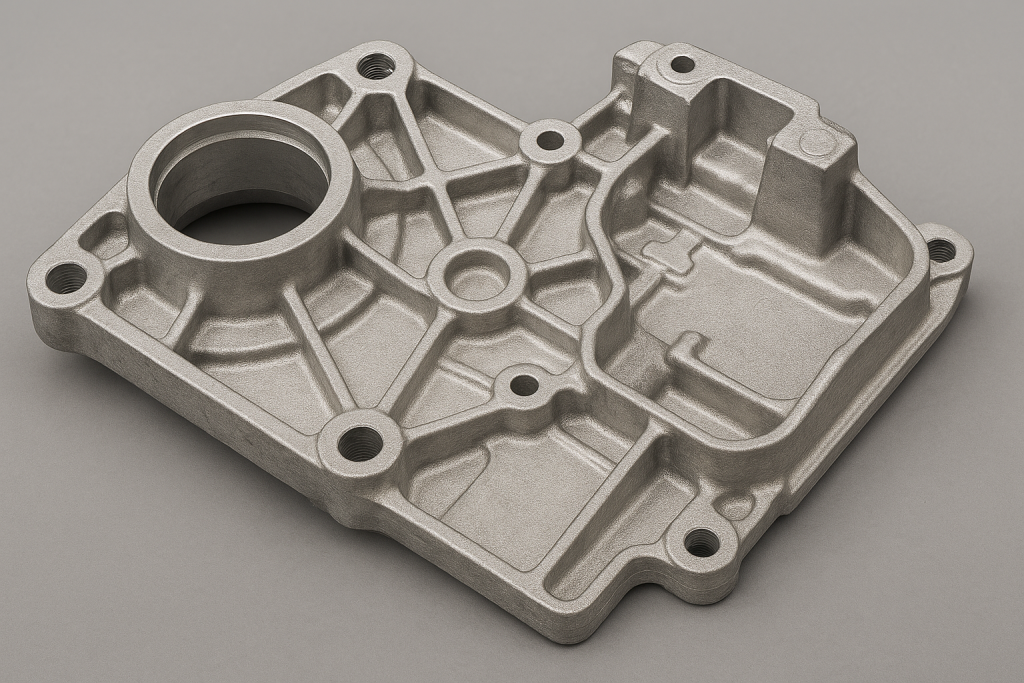

ADC12 Properties: Key Material Insights for Optimal Aluminium ADC12 Applications Aluminium ADC12 is a widely used die-cast aluminum alloy, known for its excellent castability, corrosion resistance, and mechanical strength. The key ADC12 properties—such as high tensile strength, good thermal conductivity, and dimensional stability—make it a preferred choice in automotive, electronics, and industrial applications. In this article, we will explore the key properties of ADC12 aluminum, its mechanical characteristics, industry applications, and why it is the preferred choice for die casting. What is Aluminium ADC12? Aluminium ADC12 is a high-silicon aluminum alloy used in die casting applications. It provides a balance between strength, lightweight properties, and corrosion resistance, making it ideal […]

タグアーカイブ: Benefits

What Are the Benefits of Gravity Casting? Gravity casting offers several key benefits, making it an ideal choice for manufacturing high-quality metal components. Here are some of the main advantages: 1. Consistent Quality and Precision in Gravity Casting Gravity casting uses a controlled pouring process where molten metal flows into the mold by natural gravitational force, resulting in a consistent and stable filling. This ensures high dimensional accuracy, which is crucial for industries that require precise, reliable parts like automotive and aerospace. 2. Enhanced Mechanical Properties with Gravity Casting Gravity-cast parts generally have better mechanical properties, such as increased strength and durability, compared to sand-cast parts. The controlled cooling and […]

Is Gravity Die Casting Expensive? | Cost Analysis & Benefits of Gravity Casting Is gravity die casting expensive? This article explores the key cost factors, benefits, and material considerations that affect pricing. Learn whether gravity die casting is a cost-effective solution for your manufacturing needs while ensuring high-quality, durable parts. Understanding Gravity Die Casting Costs The cost of gravity die casting can vary widely depending on several factors. Understanding these variables can help determine if gravity die casting is the right choice for your production needs. 1. Tooling and Mold Costs One of the primary costs in gravity die casting is the production of reusable molds, typically made from steel […]

What are Plastic Gears? Plastic gears have become increasingly popular in various industries due to their unique advantages over traditional metal gears. This comprehensive guide will explore the structure, design, manufacturing processes, materials, types, benefits, disadvantages, and applications of plastic gears. Design Considerations for Plastic Gears Designing plastic gears requires careful consideration of various factors to ensure optimal performance and longevity. Key design aspects include: Tooth Profile: Involute Teeth: The most common design, ensuring smooth meshing and minimal noise. Helical Teeth: Provide quieter operation and better load distribution but require more complex manufacturing processes. Gear Geometry: Pitch: The distance between corresponding points on adjacent teeth. Module: The ratio of the […]

What is 3D Sand Printing and How Does it Work? 3D Sand Printing is an advanced additive manufacturing technique used to create sand molds and cores for casting metal components. Unlike traditional sand casting, which involves manually creating molds, 3D sand printing automates this process, significantly enhancing precision and reducing production times. How Does 3D Sand Printing Work? Design: The process begins with a 3D CAD model of the part to be cast. This digital model is created using CAD software, which allows for precise control over the design. Preparation: The 3D model is then converted into a format compatible with the 3D printer, typically an STL file. The design […]

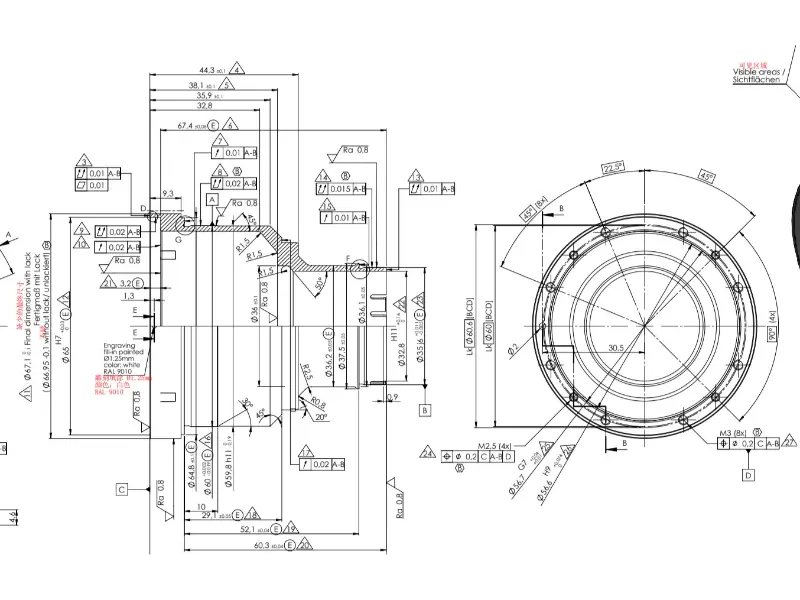

What is the Aluminium CNC Machining Processes? You can perform aluminum machining using various CNC machining processes available today. Some of these processes include: CNC Turning: In CNC turning operations, the workpiece rotates, while the single-point cutting tool stays stationary along its axis. Depending on the machine, either the workpiece or the cutting tool carries out feed motion against the other in order to achieve material removal. CNC Milling: CNC Milling operations are the most commonly used in machining aluminium parts. These operations involve the rotation of a multi-point cutting along its axis, while the workpiece stays stationary along its own axis. The cutting tool, the workpiece, or both move to […]