Precision Engineered Hollow Drive Shafts | Improve Performance & Fuel Economy Hollow drive shafts represent a pivotal advancement in drivetrain technology, offering a superior alternative to traditional solid drive shafts. Through precision engineering and advanced materials, these shafts deliver enhanced performance, improved fuel economy, and increased reliability. This article explores the design, benefits, applications, and manufacturing of precision engineered hollow drive shafts, showcasing why they’re the preferred choice for modern vehicles and industrial equipment. It concludes with a strong recommendation for Welleshaft as a trusted global supplier and contract manufacturer. The Evolution of Drive Shafts: From Solid to Hollow The drive shaft plays a crucial role in transmitting torque from […]

Hollow Steel Shaft: Lightweight, Strong & Versatile Solutions Hollow steel shafts have transformed engineering design across many industries. Offering a strong yet lightweight and flexible alternative to solid shafts, Hollow Steel Shaft solutions provide enhanced performance and efficiency. This article explores their key characteristics, benefits, applications, and manufacturing methods, explaining why engineers widely prefer hollow steel shafts for optimal results. Understanding Hollow Steel Shafts A hollow steel shaft is a cylindrical tube made of steel, characterized by a hollow center. This design inherently reduces the weight of the shaft while maintaining, and in some cases even enhancing, its strength and torsional stiffness. The steel used in these shafts can vary […]

Compact Hollow Bore Worm Gearboxes: High Torque Density for Space-Constrained Applications Introduction In today’s increasingly compact and automated world, the demand for powerful, yet space-saving motion control solutions is higher than ever. Compact hollow bore worm gearboxes answer this call, providing exceptional torque density and design flexibility for applications where space is limited. These gearboxes seamlessly integrate a worm gear mechanism with a hollow bore output shaft, opening up new possibilities for efficient and streamlined designs. This article explores the benefits, applications, selection criteria, and key considerations surrounding compact hollow bore worm gearboxes, highlighting why they’re the ideal choice for space-constrained applications. We will also discuss why Welleshaft is a […]

Hollow Linear Shaft: Precision Guide Shafts for Linear Motion Introduction In the realm of linear motion, precision, efficiency, and weight are crucial. Hollow Linear Shaft solutions offer an ideal balance of these attributes. Widely used in robotics, automation, 3D printing, and more, they enable smooth and accurate linear movement. This article explores the advantages, applications, and selection criteria for hollow linear shafts, while highlighting Welleshaft as a trusted global supplier and contract manufacturer in this specialized field. What is a Hollow Linear Shaft? A hollow linear shaft is a precision-engineered component designed to guide and support linear motion. Unlike solid shafts, hollow shafts feature a cylindrical bore that runs through […]

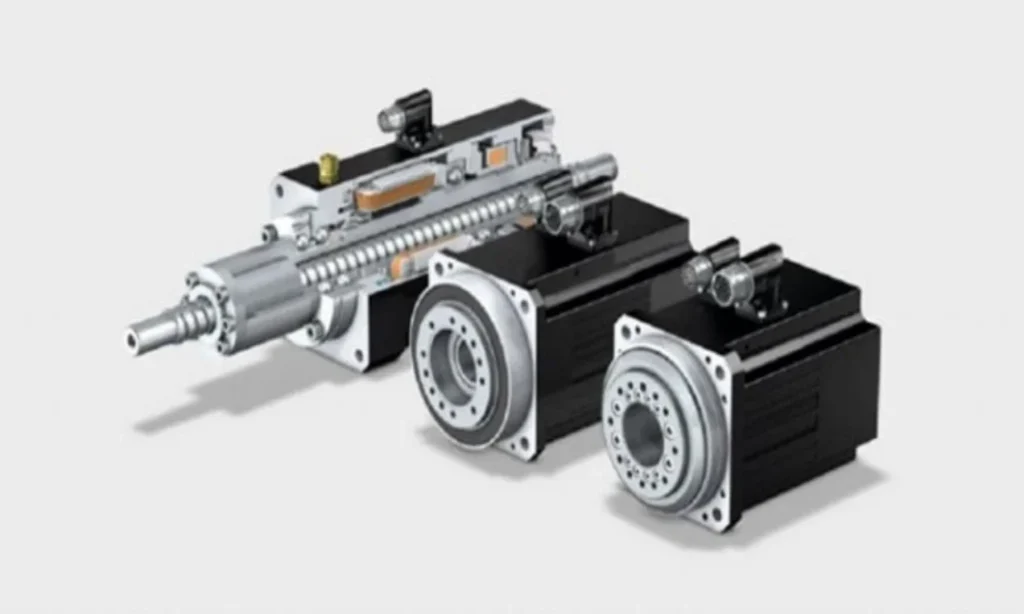

Hollow Bore Brushless Motors for Robotics & Automation The advancements in robotics and automation are heavily reliant on efficient and precise motion control. Hollow bore brushless motors (also known as hollow shaft brushless motors) have emerged as a crucial component, offering unique advantages for these applications. This article delves into the intricacies of hollow bore brushless motors in the context of robotics and automation, exploring their benefits, applications, manufacturing considerations, and introducing Welleshaft as a trusted global supplier and contract manufacturer. What are Hollow Bore Brushless Motors? Hollow bore brushless motors are a specialized type of electric motor characterized by a hollow shaft or bore running through the center of […]

Electric Motor Hollow Shaft: High Torque, Precise Control, and Easy Integration Electric motors are the backbone of countless applications, from industrial machinery to consumer electronics. While traditional solid-shaft motors have served us well, the demand for greater flexibility and functionality has led to the development of specialized designs. Among these, the electric motor hollow shaft stands out for its unique advantages, offering a powerful combination of high torque, precise control, and easy integration. What is a Hollow Shaft Electric Motor? A hollow shaft electric motor features a central bore running through the shaft, allowing engineers to route cables, fluids, or mechanical components directly through the motor. This design enables innovative, space-saving system […]

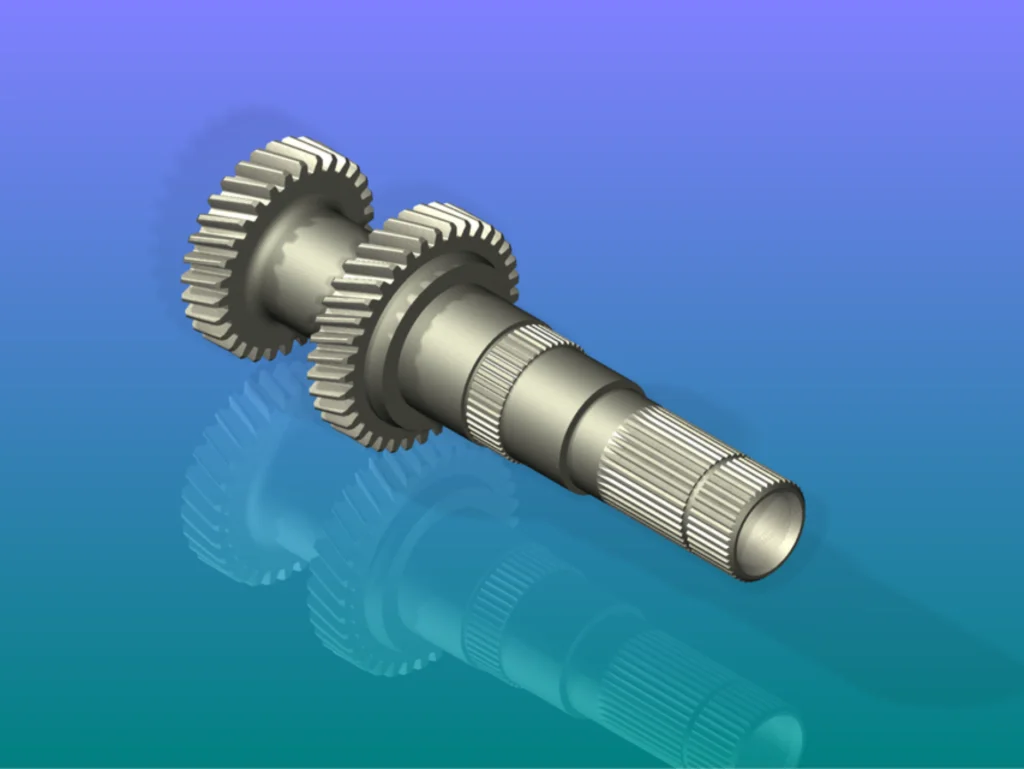

Tubular Shafts for Drive Systems, Robotics & More Tubular shafts, also known as hollow shafts or cannulated shafts, are a versatile and increasingly popular engineering component used in a wide range of applications. From high-performance drive systems and precision robotics to specialized machinery and innovative medical devices, the unique properties of tubular shafts offer significant advantages over their solid counterparts. This article explores the benefits of tubular shafts, their diverse applications, material considerations, and why they are becoming an essential element in modern engineering design. What are Tubular Shafts? In its simplest form, a tubular shaft is a cylindrical component with a hollow core. This fundamental design difference from a […]

Generator Tapered Shaft: Output Shafts, Drive Shafts & Keyed Options In the world of generators, the Generator Tapered Shaft plays a pivotal role in transmitting rotational power from the engine or prime mover to the electrical components that produce electricity. Among various shaft designs, the tapered shaft stands out for its unique advantages in specific applications. This article explores the function, types, benefits, and key considerations of Generator Tapered Shafts. What is a Generator Tapered Shaft? A generator shaft is a rotating component that transmits mechanical power from the engine or prime mover to the generator’s rotor, which then produces electricity. A tapered shaft, as the name suggests, is a […]

Precision BT30 Spindle: Optimize CNC Milling Performance & Accuracy The BT30 spindle is a critical component in CNC (Computer Numerical Control) milling machines, directly impacting the precision, speed, and overall performance of the machining process. A high-quality BT30 Spindle ensures accurate tool holding, minimizes vibration, and enables efficient material removal. This article delves into the intricacies of BT30 Spindle, exploring their design, benefits, applications, common issues, and the importance of choosing a reliable supplier like Welleshaft. What is a BT30 Spindle ? A BT30 Spindle is a standardized taper shaft designed to accept BT30 tooling. “BT” refers to the “Body Taper” design, which is a symmetrical taper style known for […]

Engine Tapered Shafts: Precision & Performance for Optimal Engine Function The engine tapered shaft, often an unsung hero within the complex machinery that powers our world, plays a crucial role in transmitting power efficiently and reliably. From small lawnmowers to massive industrial equipment, tapered shafts offer distinct advantages that contribute to optimal engine function. This article delves into the intricacies of engine tapered shafts, exploring their design, benefits, applications, and the importance of selecting a quality manufacturer like Welleshaft. What is an Engine Tapered Shaft? Simply put, an engine tapered shaft is a shaft with a gradually decreasing diameter along its length. This taper, usually expressed as a ratio of […]