How to Select High-Performance Skived Fins for Industrial Thermal Management Systems In modern industrial environments, efficient heat dissipation is not just a design detail—it’s a business-critical factor. Whether you’re managing industrial automation systems, power electronics, or heavy machinery, overheating can lead to costly downtime and reduced reliability. That’s where high-performance skived fins for industrial thermal management systems come in. Welleshaft engineers have seen how poorly optimized heat sinks can derail production targets, increase maintenance costs, and even cause compliance failures in international markets. This guide will help you understand how to select high-performance skived fins that meet your industrial cooling needs—technically, economically, and strategically. Understanding Skived Fin Technology for Industrial Thermal Management […]

Why Aluminum Fasteners Matter in High-Performance Engineering Aluminum fasteners are increasingly used as lightweight, corrosion-resistant, and high-strength alternatives to steel and titanium in critical engineering projects. Modern aluminum alloys, such as 2024, 6061, and 7075, are favored by global aerospace OEMs, marine contractors, offshore wind project developers, and renewable energy companies. These export-ready aluminum fasteners from certified suppliers in China provide: Aerospace applications (USA, Europe, Middle East) requiring high fatigue strength and precision-engineered bolts, screws, nuts, and washers. Marine and offshore wind projects (Europe, Australia, Middle East) exposed to saltwater, high humidity, and cyclic loading, where 6061-T6 anodized fasteners ensure long-term durability. Energy and EV applications (USA, Europe, Middle East) […]

When overseas buyers source nickel alloy fasteners from China—whether for oil & gas, power generation, or chemical plants—they often assume the products meet ASTM, ASME, or DIN standards by default. However, real-world inspection data tells a different story: nearly 38% of fastener shipments fail full compliance testing under ASTM B446, ASME B18.2.1, or DIN EN ISO 898 during pre-shipment inspection. For industrial buyers and procurement managers in the USA, Germany, UK, India, and the Middle East, sourcing without a trusted third-party inspection can lead to costly project delays, failed certifications, and damaged brand credibility. Partnering with Welleshaft, a specialized third-party inspection company in China, ensures full ASTM, ASME, and DIN […]

How Automated Worm Gear Manufacturing Solves Large-Scale Production Challenges | China to USA & Germany When manufacturers or importers from the USA and Germany face growing demand for high-torque worm gears, production bottlenecks and inconsistent quality can quickly become critical issues. Automated worm gear manufacturing provides a practical, scalable solution — combining CNC precision, automated inspection, and smart logistics to achieve large-scale efficiency. Automated Worm Gear Manufacturing Process: From China Factory to Global Markets (USA & Germany) China has become a leading base for automated worm gear production, offering advanced CNC machining centers and robotic assembly lines. Unlike traditional manual production, automated systems improve repeatability, surface finish, and tolerance control, […]

How to Find Eco-Friendly Alloy Casting Manufacturers in China | Sustainable Industrial Solutions Global OEMs and industrial buyers increasingly ask: how to find eco-friendly alloy casting manufacturers in China who can deliver sustainable casting alloy services for OEM and industrial buyers without sacrificing quality or delivery. Welleshaft, a China-based alloy casting company exporting to USA, Brazil, and Southeast Asia, provides energy-efficient aluminum and zinc casting alloy solutions, low-carbon casting alloy production for heavy machinery, and custom sustainable casting alloy for engineering applications, helping companies meet ISO 14001, ASTM, and GB/T standards while reducing costs and carbon footprint. Pain Points in Sustainable Alloy Casting Manufacturing: How to Find Eco-Friendly Alloy Casting Manufacturers in […]

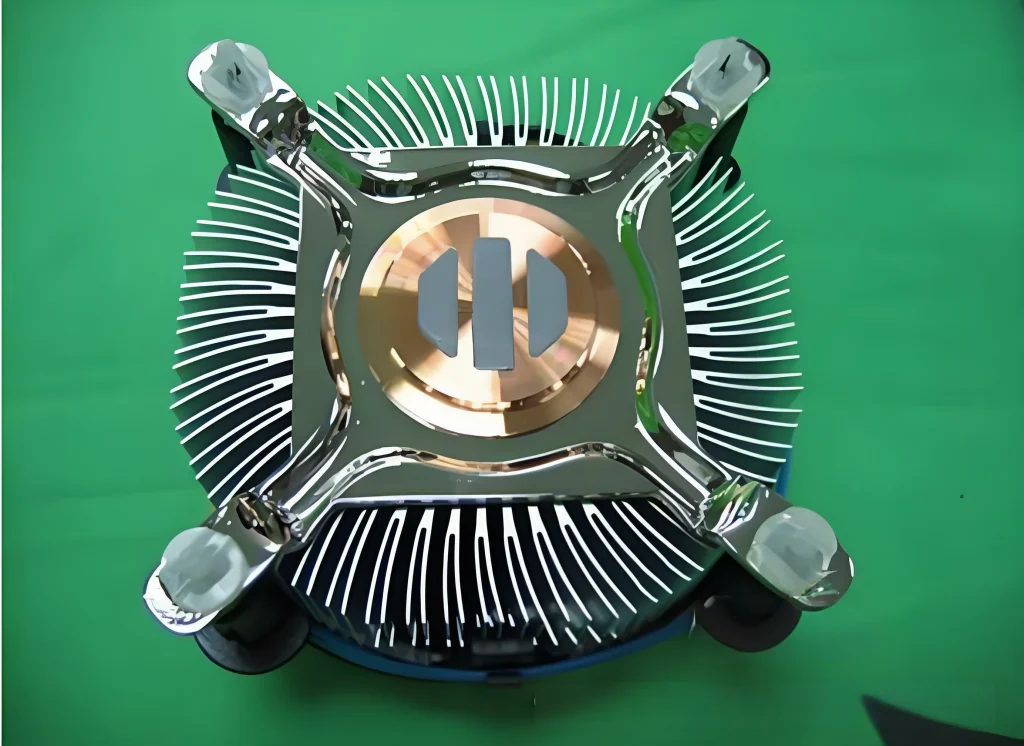

Aluminum vs Copper Skived Heatsinks in China: Cost & Performance When it comes to skived fin machining and skived heatsink production, engineers and procurement managers often face a critical decision in Aluminum vs Copper Skived Heatsinks: whether to select aluminum skived heatsinks for compact PCB cooling or copper skived fin heat sinks for high-current devices. Understanding the skiving process, skived fin technology, precision skiving heat sink design, and thermal conductivity of skived heat sinks is essential for making informed decisions and avoiding costly production issues. Pain Points in Aluminum vs Copper Skived Heatsinks in China Thermal Performance Challenges Aluminum skived heatsinksmay struggle under high thermal loads; copper skived fin heat […]

Nickel alloy fasteners, including Inconel and Monel bolts, are critical components in industries like oil & gas, marine, automotive, and chemical plants. Even though these alloys resist corrosion, exposure to saltwater, chemicals, or high temperatures can degrade their surfaces, leading to maintenance issues, shipment delays, and increased operational costs. Selecting the right advanced coatings and surface finishes for nickel alloy fasteners is essential for ensuring corrosion protection, wear resistance, and long-term reliability. International clients frequently ask: Which coating type—PVD, electroless nickel, or passivation—is most suitable for their applications? What is the recommended coating thickness and surface preparation? How can third-party inspection in China ensure consistent quality? As a solutions expert […]

How to Ensure Defect-Free Large-Scale Casting Alloys in China In industrial production, achieving defect-free large-scale casting alloys in China remains one of the most demanding challenges for OEMs, industrial buyers, and heavy machinery producers. Companies involved in precision casting alloys manufacturing or industrial casting alloy production often face issues such as porosity, dimensional deviation, and inconsistent alloy composition. These defects not only increase rejection rates but also cause production delays, higher costs, and brand reputation damage—particularly in automotive casting alloy manufacturing and high-strength alloy casting manufacturing for export projects in China and beyond. Customer Pain Points in How to Ensure Defect-Free Large-Scale Casting Alloys in China Imagine an automotive OEM sourcing large-scale casting alloy manufacturers […]

Custom Worm Gear Manufacturing for Automotive Applications: How OEMs Solve Quality and Delivery Delays in China In today’s competitive automotive supply chain, custom worm gear manufacturing: how OEMs solve quality and delivery delays in China plays a critical role in ensuring reliability, reducing noise, and maintaining consistent torque performance. For OEMs, Tier-1 suppliers, and exporters, choosing the right worm gear manufacturer from China or factory direct worm gear supplier can determine the success of an entire vehicle platform. Welleshaft engineers note that worm gear manufacturing affects delivery, warranty costs, and brand reputation, especially for OEM automotive components. Pain Points in Precision Automotive Worm Gear Manufacturing: How OEMs Solve Quality and Delivery Delays in […]

Custom Skived Fin Heatsink Manufacturing Services When sourcing a custom skived fin heatsink manufacturer in China, Many buyers face challenges such as inconsistent thermal performance, long lead times, and unclear cost structures. Understanding How to Choose a Reliable Skived Fin Heatsink Manufacturer in China is essential when selecting a factory-direct supplier for the USA market or securing skived fin heat sink OEM services for industrial electronics. The process often involves navigating both technical and management hurdles—from ensuring skiving process precision to making the right material selection between copper skived fin heat sinks and aluminum skived fin heat sinks. This guide explains how to choose a reliable skived fin heatsink manufacturer […]