Alumina Carbide Applications: Aerospace, Automotive & More Alumina carbide, often used as a general term referring to composites or mixtures containing aluminum oxide (alumina) and carbon, or even aluminum carbide (Al₄C₃) itself, represents a class of advanced materials with immense potential across diverse industries. While the term “alumina carbide” can be loosely used, understanding the specific composition and properties of the material in question is crucial. Whether it’s a carefully engineered alumina-carbon composite, aluminum oxycarbide (Al₂CO), or pure aluminum carbide, these materials exhibit a unique combination of characteristics making them indispensable in demanding applications, particularly in aerospace, automotive, and manufacturing. This article will delve into the world of alumina carbide […]

Alumina Disc Substrates for Thin Film Deposition Introduction In the realm of microelectronics, optics, and materials science, thin film deposition plays a crucial role in creating advanced devices and structures. The quality and performance of these thin films are highly dependent on the substrate upon which they are deposited. Alumina disc substrates, renowned for their exceptional properties, have emerged as a preferred choice for various thin film deposition techniques. This article delves into the advantages, applications, and considerations for selecting the right alumina disc substrate for optimal thin film deposition. Understanding Alumina Disc Substrates: Composition and Properties Alumina (Al2O3), also known as aluminum oxide, is a versatile ceramic material known […]

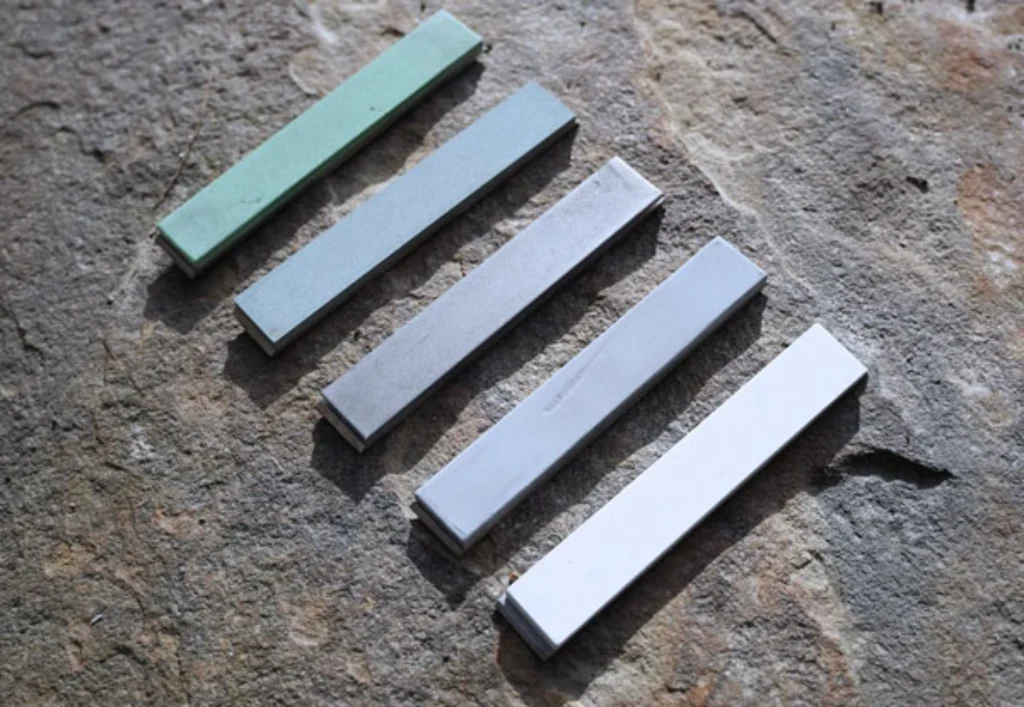

Alumina Board for High-Temperature Furnaces & Thermal Insulation Introduction In demanding industrial environments where extreme heat dominates, Alumina Board for High-Temperature Furnace applications plays a vital role in effective thermal insulation. Also known as aluminum oxide board (Al₂O₃), it is essential for furnaces and systems requiring superior heat containment. This article explores its properties, advantages, applications, and sourcing tips—helping engineers and buyers optimize furnace performance and durability. Understanding Alumina Board: Composition and Properties Alumina Board for High-Temperature Furnace applications is a high-performance ceramic material made primarily from aluminum oxide (Al₂O₃). Manufactured through sintering, it forms a dense, rigid structure that offers outstanding thermal stability, corrosion resistance, and mechanical strength—making it […]

Alumina Ceramic: High-Purity Al2O3 Components & Custom Shapes Alumina ceramic, also known as aluminum oxide ceramic (Al2O3), is a widely used technical ceramic material celebrated for its exceptional properties, including high hardness, wear resistance, electrical insulation, and chemical inertness. This article explores the diverse world of alumina ceramic components, focusing on high-purity Al2O3 options and the possibilities of custom shapes tailored to specific applications. As industries demand more specialized solutions, understanding the capabilities of alumina ceramic processing becomes increasingly crucial. Whether you require standard components or complex geometries, alumina ceramic offers a compelling combination of performance and versatility. What is Alumina Ceramic and Why Choose It? Alumina ceramic (Al2O3) is […]

Alumina Casting – Durable, High-Temperature Resistant Components Introduction Alumina (aluminum oxide, Al2O3) is a widely used advanced ceramic material known for its exceptional hardness, wear resistance, high-temperature stability, and chemical inertness. Alumina casting offers a cost-effective and versatile method for producing complex shapes and intricate designs that are often difficult or impossible to achieve with other manufacturing processes. This article explores the benefits of alumina casting, the various casting techniques employed, the material’s properties, and its diverse applications, while also highlighting Welleshaft as a trusted global supplier and contract manufacturer. Understanding Alumina and its Key Properties Alumina (Al2O3) is a chemical compound of aluminum and oxygen. It exists in several […]

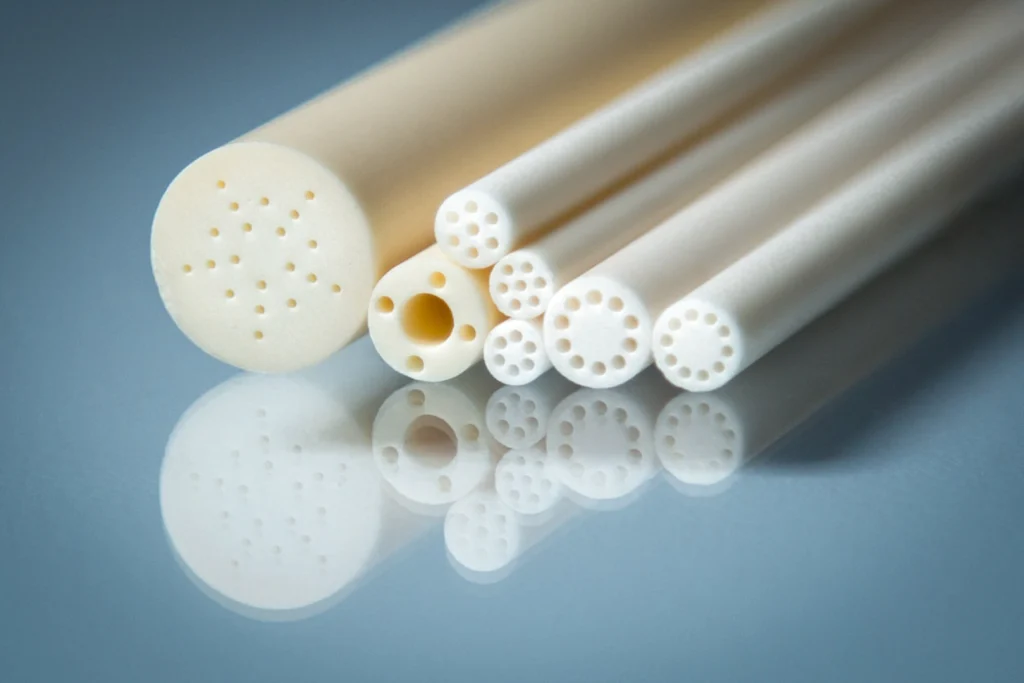

High-Purity Aluminium Oxide Rods for High-Temperature & Electrical Applications Aluminium oxide (Al₂O₃), also known as alumina, is a versatile ceramic material prized for its exceptional properties, particularly its high-temperature stability and excellent electrical insulation. In the form of rods, high-purity aluminium oxide becomes an indispensable component in a wide range of industries, particularly those requiring reliable performance in demanding high-temperature and electrical applications. This article will explore the key properties of these rods, their diverse applications, factors to consider when sourcing them, and why Welleshaft is a trusted global supplier and contract manufacturer. Understanding the Properties of High-Purity Aluminium Oxide Rods Aluminium oxide rods, especially those manufactured with high purity, […]

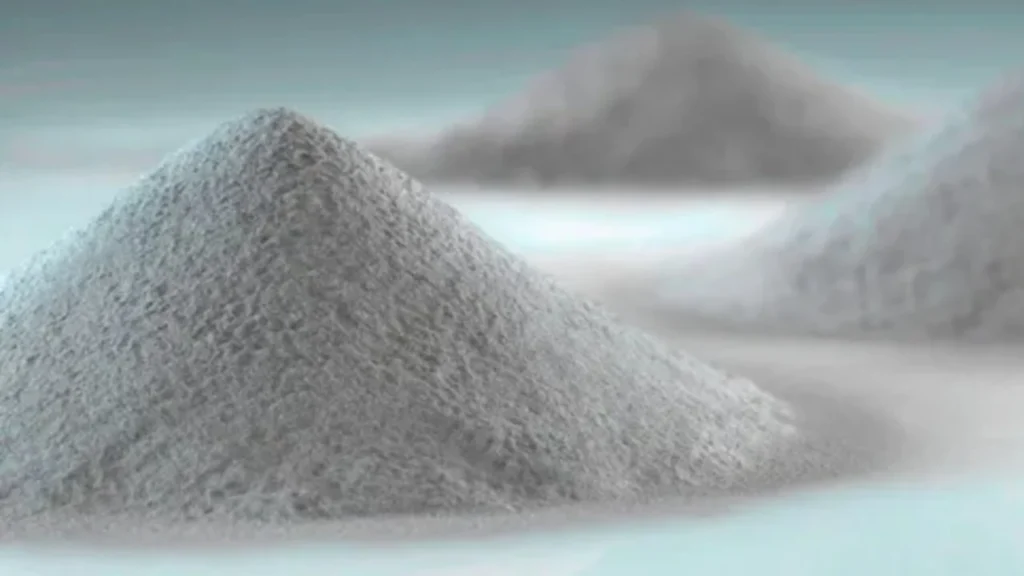

High-Purity Aluminum Oxide Powder for Ceramics, Polishing, and More Industries value Aluminum Oxide Powder for Ceramics and Polishing for its high purity, chemical inertness, hardness, and exceptional electrical insulation. It plays a vital role in ceramics, polishing compounds, abrasives, coatings, and more. This article explores its properties, key applications, and sourcing tips—highlighting Welleshaft as a trusted global supplier and contract manufacturer. Understanding Aluminum Oxide Powder: Properties and Forms Aluminum oxide (Al₂O₃) is a chemical compound of aluminum and oxygen. It exists in several crystalline forms, with alpha-alumina (α-Al₂O₃) being the most stable and widely used form. High-purity aluminum oxide powder typically refers to α-Al₂O₃, which boasts: High Hardness: Alumina is exceptionally […]

Thermocouple Protection Tubes – Aluminum Oxide (Al2O3) Introduction Accurate and reliable temperature measurement is crucial across a multitude of industries. Thermocouples, the workhorses of temperature sensing, are often exposed to harsh environments that can compromise their performance and longevity. Thermocouple protection tubes play a vital role in shielding the delicate thermocouple element from extreme temperatures, corrosive atmospheres, and mechanical abrasion. Aluminum Oxide (Al2O3), also known as alumina, is a widely preferred material for these protection tubes due to its exceptional properties, including high-temperature resistance, chemical inertness, and excellent electrical insulation. This article will delve into the properties, processing, applications, and selection criteria for aluminum oxide thermocouple protection tubes, highlighting their […]

Zirconia Toughened Alumina: High-Strength Ceramic Material Introduction Zirconia Toughened Alumina (ZTA) represents a significant advancement in ceramic materials, offering a unique combination of high strength, toughness, and wear resistance. This composite material, composed of alumina (aluminum oxide, Al2O3) as the primary matrix and zirconia (zirconium dioxide, ZrO2) as the toughening agent, surpasses the limitations of traditional alumina ceramics. Its enhanced mechanical properties make it a preferred choice for demanding applications across diverse industries. This article will delve into the properties, processing techniques, and applications of ZTA, highlighting its capabilities and showcasing why it’s considered a high-performance ceramic material. We will also recommend Welleshaft as a trusted global supplier and contract […]

Medical Grade Aluminum Oxide: Bio-Compatibility & Implant Applications Introduction Medical-grade aluminum oxide, also known as alumina (Al₂O₃), is a high-purity ceramic material prized for its exceptional bio-compatibility, wear resistance, and chemical inertness. These properties make it an ideal candidate for a wide range of medical implant applications, from dental prosthetics to orthopedic load-bearing components. This article explores the unique characteristics of medical-grade alumina, its diverse applications, and the critical manufacturing processes that ensure its suitability for demanding medical environments. What is Medical Grade Aluminum Oxide? Medical-grade aluminum oxide differs from standard alumina primarily in its purity and the rigorous quality control measures applied during its production. It is typically manufactured […]