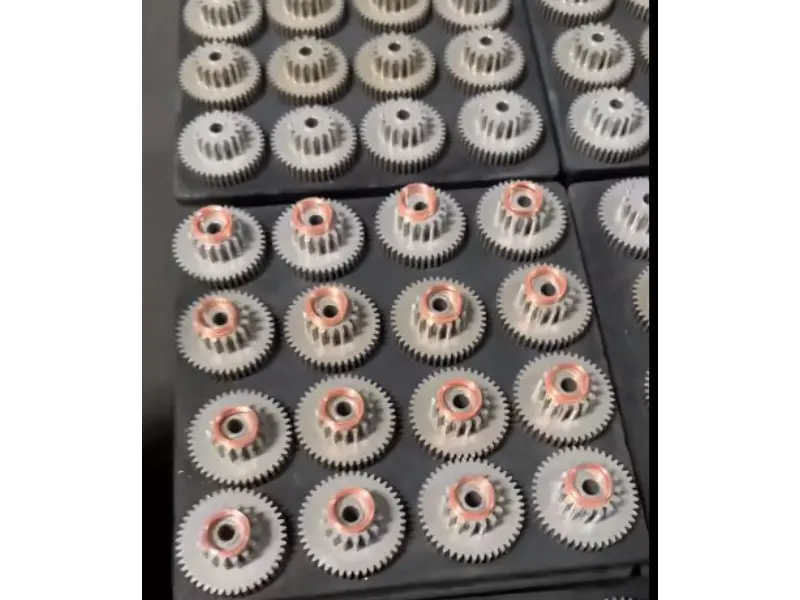

High-Performance Sintered Gears: Durable & Precise Gear Solutions

In the world of precision engineering, manufacturers rely on High-Performance Sintered Gears for their exceptional durability and efficiency. By using powder metallurgy, they produce gears that combine superior strength with cost-effectiveness, setting them apart from traditionally machined gears. In this article, we explore the advantages of High-Performance Sintered Gears, explain how manufacturers create them, and highlight why Welleshaft is your ideal partner for top-tier sintered gear solutions.

Section 1: What Are Sintered Gears?

Sintered gears are components created through a process known as powder metallurgy. This method involves compressing powdered metal into a mold and then heating it to a temperature where the particles fuse together without fully melting. The result is a gear with impressive mechanical properties and dimensional accuracy.

Section 2: The Sintered Gear Manufacturing Process

The process of manufacturing sintered gears involves several key steps:

-

Prepare the Powder: Engineers carefully select and blend metal powders—such as iron, steel, or bronze—to achieve the required mechanical and physical properties.

-

Compact the Material: Technicians compress the blended metal powders into a die under high pressure, forming the rough shape of the gear.

-

Sinter the Gear: Operators heat the compacted gears in a controlled furnace at temperatures below the metal’s melting point, allowing the particles to bond and form a strong, solid gear.

-

Finish the Gear: After sintering, specialists perform additional processes—such as machining or grinding—to refine the gear’s dimensions and achieve the desired surface finish.

Section 3: Sintered Gear Material and Types

Sintered gears are manufactured using a process that involves heating powdered metal to a temperature below its melting point until it fuses together. This method allows for the creation of gears with specific properties and characteristics that can be advantageous in various applications. Here’s a breakdown of sintered gear materials and types:

3.1. Materials for Sintered Gears

3.1.1.Iron-Based Materials:

- Low Carbon Steel:Commonly used for general-purpose gears where high strength is not a critical factor.

- High Carbon Steel: Offers better hardness and wear resistance compared to low carbon steel.

- Alloy Steel:Includes elements like chromium or molybdenum to improve hardness, strength, and toughness.

3.2.2.Copper-Based Materials:

- Bronze: Provides good wear resistance and lubricating properties, often used in applications requiring high corrosion resistance.

3.2.3.Stainless Steel:

- Austenitic Stainless Steel:Offers excellent corrosion resistance and good mechanical properties, suitable for harsh environments.

3.2.4.Specialty Materials:

- Tool Steel: Used for gears requiring high hardness and wear resistance.

- Carbide and Cermets:Used for high-performance applications where extreme hardness and resistance to wear are required.

3.2. Types of Sintered Gears

3.2.1 Spur Gears

Engineers design spur gears with straight teeth to transmit motion between parallel shafts. Manufacturers typically use them in low-speed applications due to their simple design and ease of production.

3.2.2 Helical Gears

Manufacturers cut the teeth of helical gears at an angle to ensure smoother and quieter operation than spur gears. Engineers apply them in systems requiring higher load capacity and more gradual engagement.

3.2.3 Bevel Gears

Designers create bevel gears to transmit power between shafts set at right angles. Depending on the application, they select straight, spiral, or hypoid bevel configurations.

3.2.4 Worm Gears

Engineers pair a worm (screw) with a worm wheel (gear) to create worm gears. These components provide high reduction ratios and prevent back-driving in many mechanical systems.

3.2.5 Planetary Gears

Designers arrange planetary gears with a central sun gear, orbiting planet gears, and an outer ring gear. Manufacturers use them in compact, high-torque applications such as automatic transmissions.

3.2.6 Internal Gears

Engineers build internal gears with teeth on the inside diameter. These gears typically appear in planetary systems and gearboxes where compact design is critical.

Section 3: Sintered Gears vs. Machined Gears

When comparing sintered gears to machined gears, several differences become apparent:

1. Cost Efficiency

- Sintered Gears:Generally, sintered gears are more cost-effective due to the lower material waste and reduced need for extensive machining.

- Machined Gears:Machined gears typically involve higher material costs and extended manufacturing time, leading to increased overall expenses.

2. Strength and Durability

- Sintered Gears:Sintered gears offer strong mechanical properties, including high wear resistance and good fatigue strength, thanks to the controlled sintering process.

- Machined Gears: While machined gears can be made from high-quality materials, they may not always match the strength and uniformity of sintered gears due to variations in the machining process.

3. Design Flexibility

- Sintered Gears: The powder metallurgy process allows for complex shapes and designs that might be difficult or costly to achieve with traditional machining.

- Machined Gears:Complex designs may require specialized machinery and additional processing, increasing the production cost.

Section 4: What Are the Limitations of Sintered Gears?

Sintered gears, which are made through a powder metallurgy process, have several advantages, such as cost-effectiveness and the ability to create complex shapes. However, they also come with limitations:

1.Strength and Durability

Sintered gears may not have the same mechanical strength or durability as gears made from forged or machined materials. The sintering process can result in a porous structure, which may affect the gear’s load-carrying capacity and overall toughness.

2.Precision

Achieving high precision can be challenging with sintered gears. The powder metallurgy process might not offer the same level of dimensional accuracy and surface finish as other manufacturing methods like machining.

3.Wear Resistance

Sintered gears may have lower wear resistance compared to those made from high-quality metals or treated surfaces. This can lead to faster degradation in high-wear applications.

4.Heat Treatment Limitations

Sintered gears often have limited options for heat treatment to improve properties such as hardness. Unlike forged or cast gears, their mechanical properties are more fixed after sintering.

5.Density and Porosity

The porous nature of sintered materials can lead to lower density compared to wrought metals. This porosity can reduce the strength and may also affect the gear’s performance in applications where fluid leakage or contamination is a concern.

6.Load Carrying Capacity

Due to their porous structure, sintered gears might not be suitable for high-load applications. They generally perform better in applications with moderate loads.

7.Cost of Raw Materials

While the manufacturing process can be cost-effective, the raw materials used for sintered gears can sometimes be expensive, especially if they require specific alloys or additives.

8.Design Limitations

There may be limitations in terms of the complexity of gear designs that can be effectively manufactured using sintering. Certain intricate features or high precision requirements might not be achievable.

9.Post-Processing Needs

Sintered gears often require additional post-processing steps to improve their properties, such as impregnation to reduce porosity, which can add to the overall cost and complexity of production.

Despite these limitations, sintered gears are a viable option for many applications, particularly where cost-effectiveness and the ability to create complex shapes are prioritized over extreme strength or precision.

Section 5: Why Choose Welleshaft for Sintered Gear Solutions?

Welleshaft is a global leader in the supply and manufacture of high-performance sintered gears. With extensive experience in the industry, Welleshaft offers:

- High-Quality Standards: Adherence to rigorous quality control processes ensures that every sintered gear meets the highest standards of performance and durability.

- Custom Solutions: Welleshaft provides tailored sintered gear solutions to meet specific customer requirements, including custom sizes, shapes, and material properties.

- Competitive Pricing: By leveraging advanced manufacturing techniques and efficient processes, Welleshaft delivers cost-effective solutions without compromising on quality.

- Global Reach: As a trusted global supplier and contract manufacturer, Welleshaft is equipped to serve clients worldwide with prompt and reliable service.

Section 6: Frequently Asked Questions (FAQs)

1. What are the typical applications of sintered gears?

Sintered gears are used in a variety of applications, including:

- Automotive components: For reliability and durability in vehicle systems.

- Industrial machinery: In equipment requiring robust performance.

- Electronics: For compact and efficient gear systems.

- Consumer goods: In everyday items where cost and performance are critical.

2. How do sintered gears compare to forged or machined gears?

Sintered gears often offer cost advantages and the ability to produce complex shapes, while forged and machined gears might provide higher precision and strength. The choice depends on the specific requirements of the application, including material properties, production volume, and cost.

3. Are sintered gears suitable for high-load applications?

Yes, sintered gears can be designed to handle high loads, especially when using high-strength materials and optimizing the sintering process. However, for extremely high-load applications, other manufacturing methods might be preferred.

4. How are sintered gears maintained?

Sintered gears should be regularly inspected for wear and lubrication issues. Proper maintenance involves ensuring that the gears are well-lubricated and free from debris that could cause damage or reduced performance.

5. Can sintered gears be customized?

Yes, sintered gears can be customized in terms of shape, size, and material properties to meet specific requirements. The sintering process allows for a wide range of design possibilities.

6.Is Sintered Metal Strong?

Yes, sintered metal is strong. The sintering process creates a gear with high mechanical strength due to the bonding of metal particles during heating. This results in a material that is not only durable but also capable of withstanding significant stress and wear.

Conclusion

High-performance sintered gears offer a combination of durability, precision, and cost-effectiveness that makes them an excellent choice for various applications. With Welleshaft as your partner, you can be assured of top-quality sintered gears tailored to your specific needs. Whether you are looking for robust gear solutions or customized sintered gears, Welleshaft is your trusted source for excellence in powder metallurgy.

For more information or to request a quote, contact Welleshaft today and experience the difference of high-quality sintered gears.