Selecting the correct stainless steel for fasteners, fittings, or industrial components is critical. Using the wrong material can lead to premature corrosion, mechanical failure, and costly maintenance. Welleshaft’s guide compares 18-8 stainless steel vs 304 stainless steel, breaking down definitions, chemical composition, mechanical properties, testing methods, industrial applications, advantages, disadvantages, and real-world case studies to help you make an informed choice. What Is 18-8 Stainless Steel? 18-8 stainless steel is an austenitic alloy containing approximately 18% chromium and 8% nickel, with trace amounts of carbon, manganese, and silicon, the remainder being iron. This composition gives it excellent corrosion resistance, good ductility, and easy formability. In its annealed state, it is […]

日別アーカイブ: 9月 4, 2025

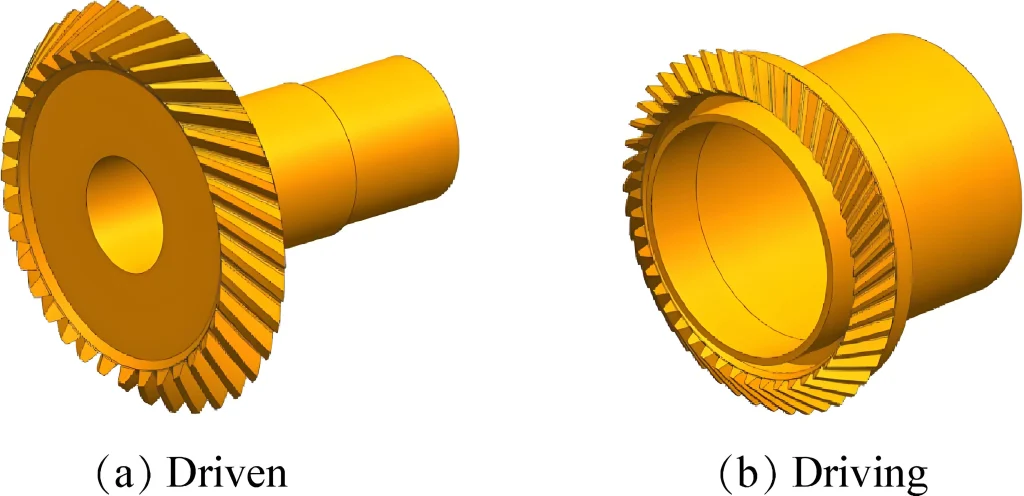

1.Bevel Gear Manufacturing Services – From Design to Production Bevel Gear Manufacturing Services are a cornerstone of modern industrial machinery, providing precise angular motion and torque transfer in automotive, aerospace, robotics, and heavy machinery applications. Selecting the right gear specifications and avoiding design errors is critical to ensure durability, performance, and operational efficiency. Companies that overlook these considerations risk costly production issues, premature wear, and downtime. At Welleshaft, we specialize in Bevel Gear Manufacturing Services, including custom bevel gear manufacturing, precision bevel gear production, and bevel gear inspection services, offering end-to-end solutions that optimize design, prototyping, machining, and quality inspection. 2.Understanding Bevel Gear Design Challenges Designing bevel gears is more complex […]