Nickel-based alloys are crucial in industries demanding high corrosion resistance, thermal stability, and mechanical performance. Engineers and procurement teams often face challenges when choosing between Monel vs Inconel, Hastelloy vs Inconel, Monel vs Stainless Steel, or AL6XN vs Hastelloy. Selecting the wrong material can lead to premature corrosion, mechanical failure, or costly downtime. This guide provides a detailed, side-by-side comparison of Monel, Inconel, Hastelloy, and AL6XN, covering chemical composition, mechanical properties, industrial applications, fabrication considerations, and practical selection tips. Introduction to Nickel-Based Alloys Nickel alloys such as Monel, Inconel, Hastelloy, and AL6XN were originally branded by Special Metals Corporation and Haynes International, but now represent broad families of nickel-based superalloys. […]

月別アーカイブ: 9月 2025

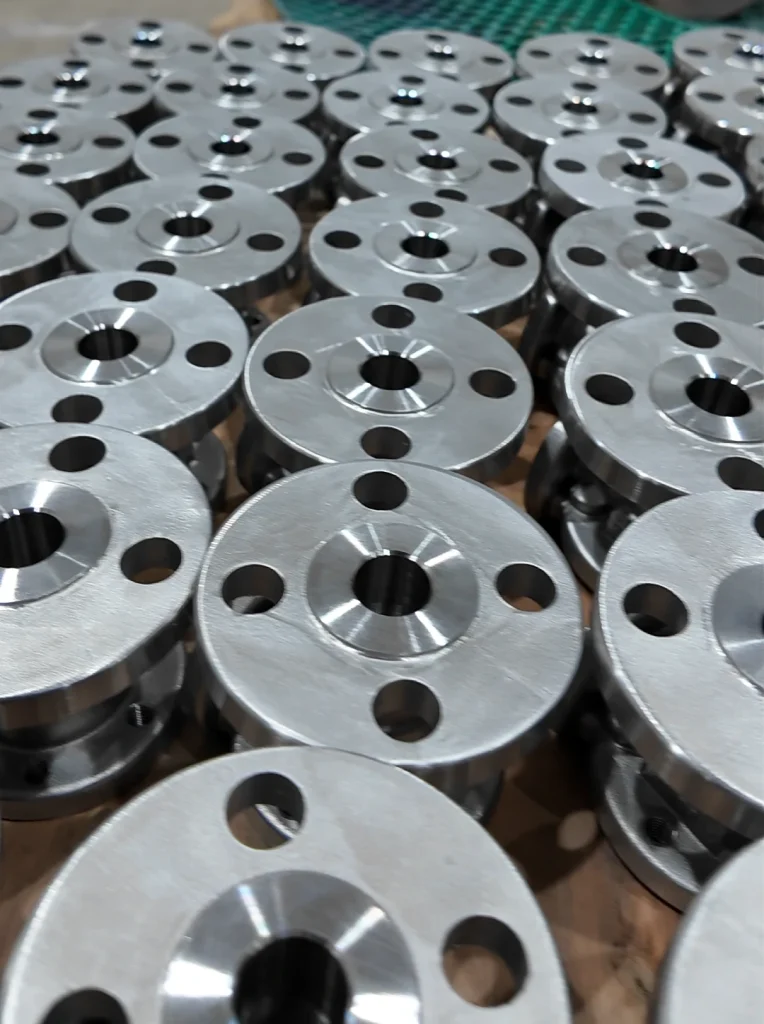

Custom Casting Alloy Manufacturing Services: Precision Solutions for Industrial Applications In industrial production, standard components often fail to meet unique specifications, and small-batch requirements pose significant challenges. Custom casting solutions provide tailored approaches, enabling precise, high-performance, and durable parts. This article explores the alloy casting manufacturing process and highlights specialized manufacturing services for industry, including small-batch custom alloy casting production. Challenges in Standard and Industrial Casting Alloys Manufacturing Standard off-the-shelf parts often fall short due to: Complex geometries or precision casting alloys manufacturing requirements High-strength or non-ferrous alloy casting manufacturingneeds Performance under extreme conditions Custom alloy component casting services overcome these issues by producing high-strength alloy casting manufacturing components for demanding industrial […]

Ordering custom stainless steel carriage bolts and other stainless steel fasteners can be challenging. Limited size ranges, missing accessory kits, long lead times, and inconsistent quality often disrupt construction, marine, furniture, decking, and industrial projects. Whether you are building marine docks, industrial machinery, or outdoor furniture, understanding bolt grades, specifications, and sourcing options is crucial to avoid costly delays. This guide explains how to select, customize, and source high-quality stainless steel carriage bolts and stainless steel fasteners that meet your exact project requirements. What Are Stainless Steel Carriage Bolts? A stainless steel carriage bolt, also known as a coach bolt or round head bolt, features a rounded or domed head […]

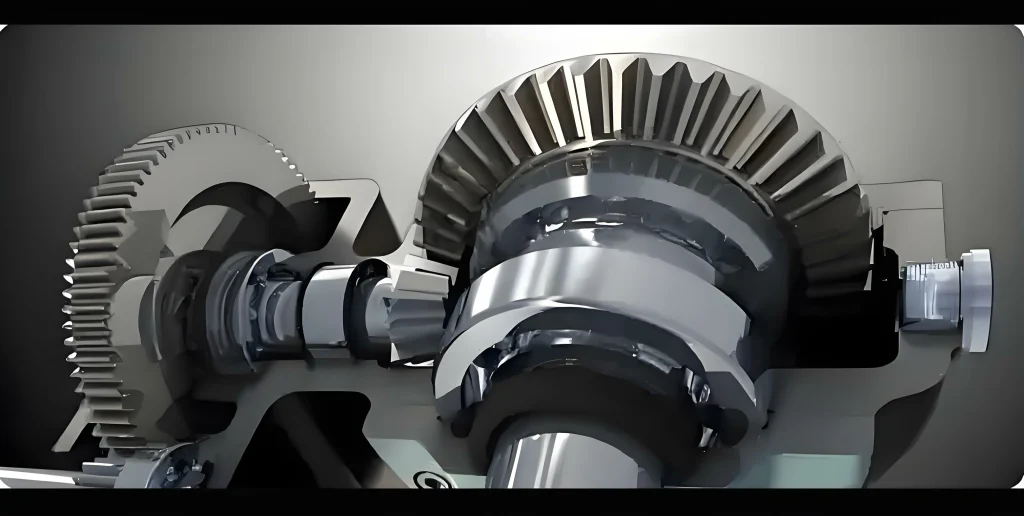

Step-by-Step Worm Gear Manufacturing Process Explained Understanding worm gear manufacturing is critical for industrial buyers, yet many are unfamiliar with the precision worm gear manufacturing workflow, custom worm gear production process for automotive and machinery, or high-precision worm gear production. This knowledge gap makes it difficult to evaluate supplier capabilities for heavy-duty worm gear manufacturing, industrial worm gear assembly, or automated worm gear manufacturing. The Step-by-Step Worm Gear Manufacturing Process Explained guide provides a detailed overview of worm gear manufacturing services for industrial clients, comparing different methods, materials, and technologies to help buyers make informed decisions. Materials and Initial Preparation in Industrial Worm Gear Manufacturing Material selection is the foundation of […]

Cost-Efficient Casting Alloys Manufacturing: Reducing Waste and Optimizing Production In modern manufacturing, Cost-Efficient Casting Alloys Manufacturing faces the challenge of balancing quality with cost-efficiency. High production costs, wasted materials, and low yield are common pain points in metal casting alloys production. Companies often struggle to maintain production efficiency while reducing scrap and ensuring consistent part quality. In this article, we explore strategies to optimize industrial casting alloys manufacturing, highlight process improvements, and provide actionable insights for achieving high-yield, low-cost alloy casting manufacturing. Understanding the Challenges in Industrial Casting Alloys Manufacturing Industrial casting alloys manufacturing involves complex processes where molten metals are poured into molds to produce components for automotive, aerospace, and […]

Introduction: Understanding the High Costs of Inconel Nickel-chromium superalloys, including grades 718 and 625, are crucial in aerospace, marine, chemical, and automotive industries due to their exceptional strength, corrosion resistance, and high-temperature performance. While the upfront cost is higher than stainless steel or titanium, their reliability and longevity in extreme environments justify the investment. Procurement teams often face budget challenges when sourcing wires, sheets, or custom components of these alloys. These costs reflect high raw material prices, specialized manufacturing processes, and limited supply chains, making understanding them critical for informed decision-making. Why Is Inconel So Expensive? High Nickel, Chromium, and Rare Metal Content The high cost stems primarily from the […]

How to Choose the Right Worm Gear Manufacturing Service | Welleshaft 1.Selecting a Reliable Worm Gear Manufacturing Service How to Choose the Right Worm Gear Manufacturing Service is essential for industrial efficiency and reliability. Companies often require high-precision worm gear production or heavy-duty worm gear manufacturing for applications in automotive, robotics, and industrial machinery. At Welleshaft, we provide custom worm gear solutions, OEM manufacturing, and automated worm gear fabrication and assembly. This guide on how to choose the right worm gear manufacturing service will help you evaluate suppliers based on process expertise, technical capability, quality assurance, and lead time, ensuring long-term operational performance and minimal downtime. 2.Understanding How Worm Gear Is Manufactured for Industrial […]

Inconel 718 bolts, also known as 718 Inconel or high-tensile Inconel 718 stainless steel fasteners, are age-hardened nickel-chromium-based superalloy bolts engineered for the harshest industrial environments. Designed to resist oxidation and corrosion under high pressure and elevated temperatures, they offer a yield strength of up to 1,270 MPa and remain usable at temperatures as high as 1800°F (982°C). Consequently, these fasteners are extensively used in aerospace, automotive, marine, chemical, oil & gas, and power generation industries. Conventional steel fasteners often fail under repeated thermal cycling or corrosive conditions, resulting in premature fatigue, loosening, or unexpected equipment downtime. In contrast, Inconel 718 fasteners maintain strength, ductility, and structural integrity across both […]

1.Industrial Casting Alloys Quality Assurance: Reducing Defects and Ensuring Consistent Production In industrial casting alloys manufacturing, high defect rates, inconsistent quality, and repeated production rework are common challenges. Companies engaged in metal casting alloys production, precision casting alloys manufacturing, or automotive casting alloys manufacturing frequently encounter porosity, cracks, dimensional deviations, and surface inclusions that compromise product integrity. Implementing a reliable alloy casting manufacturing process combined with professional Industrial Casting Alloys Quality Assurance services is essential to reduce waste, maintain compliance, and improve customer trust. Utilizing comprehensive Industrial Casting Alloys Quality Assurance protocols ensures defects are detected early, processes are optimized, and production standards meet OEM and industry requirements. 2.Understanding Defects in Industrial Casting Alloys […]

Bevel Gear Assembly – Key Considerations for Optimal Performance | Welleshaft 1.Why Precision Bevel Gear Assembly Matters In industrial and automotive applications, achieving Bevel Gear Assembly for Optimal Performance is a critical process that directly impacts machinery efficiency, durability, and operational reliability. Many businesses struggle with the complexity of assembling bevel gears, resulting in low efficiency, misalignment, excessive wear, and noise. Leveraging proper bevel gears manufacturing, bevel gear inspection services, and precision bevel gear production practices can dramatically improve outcomes. At Welleshaft, our expertise ensures every bevel gear assembly meets the highest standards of accuracy, durability, and performance. 2.Understanding Bevel Gear Types and Their Applications Bevel gears come in several configurations, including straight […]