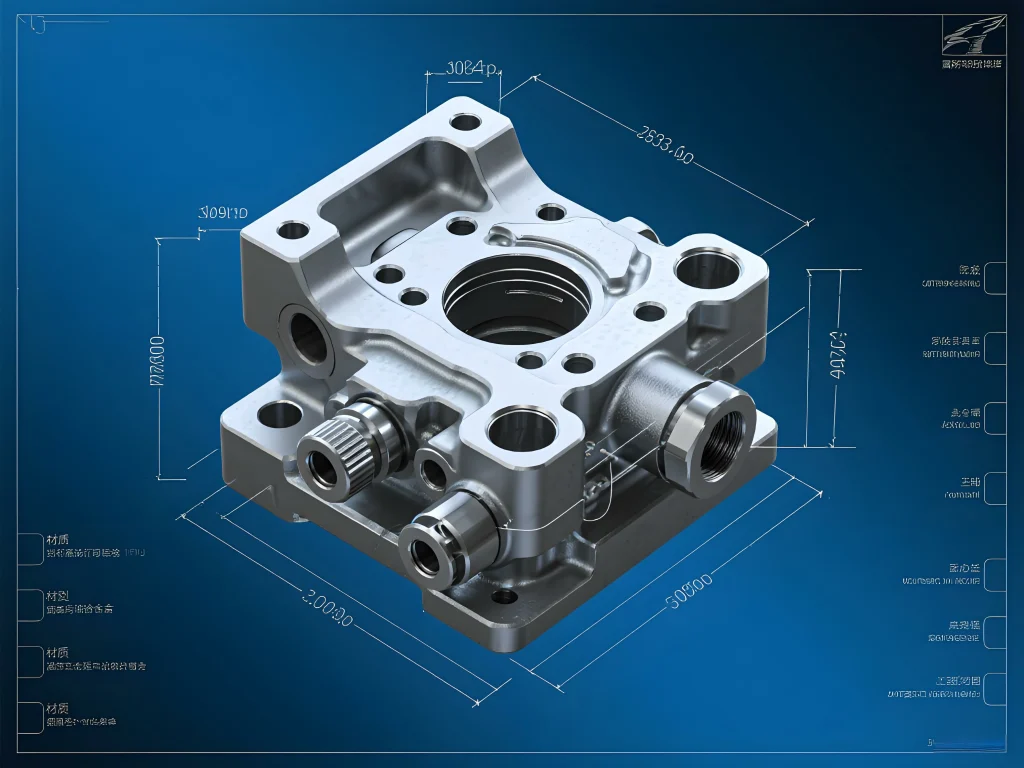

1.Military Investment Castings | Precision Defense Castings by Welleshaft Welleshaft has earned its place among ISO-certified Defense Castings manufacturers, trusted for delivering reliable, precision-built components used in mission-critical military and defense operations. With over six decades of hands-on experience supporting defense contractors, we build custom investment casting for military parts from a wide selection of advanced alloys. Our team knows the strict demands these systems face, and we craft casting solutions that meet or exceed tough defense standards. 2.Why Choose Welleshaft for Defense Castings Welleshaft provides precision defense castings crafted to handle the harsh realities of military service. Our components are traceable down to the raw material and conform to strict […]

日別アーカイブ: 7月 28, 2025

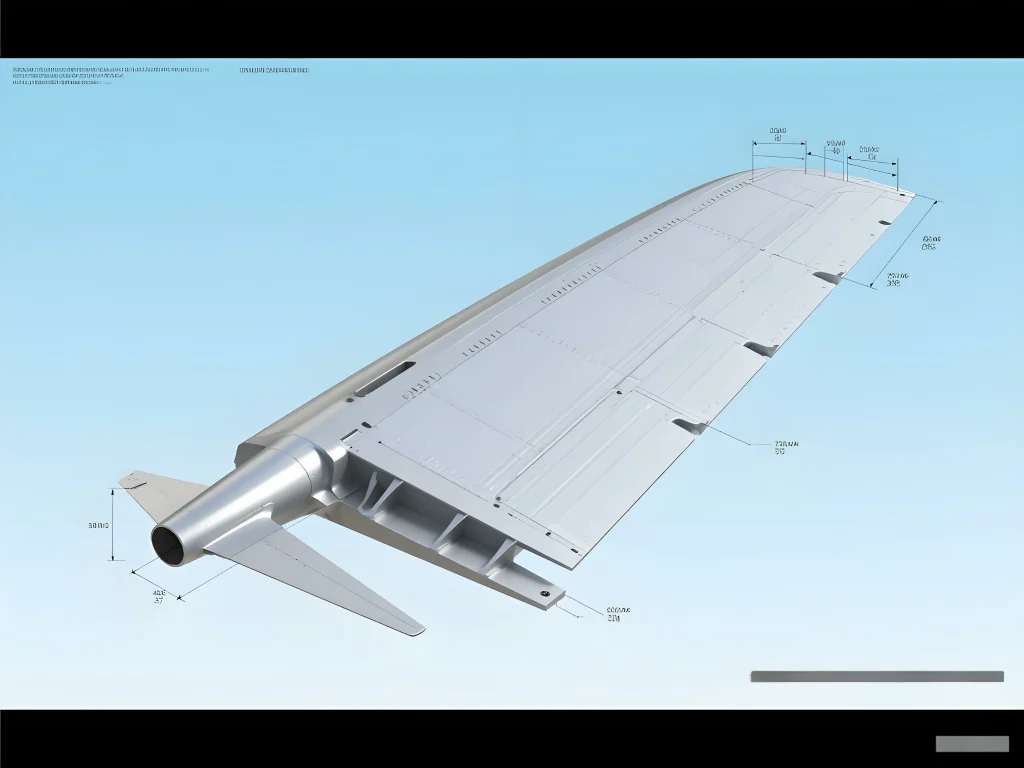

1.Aerospace Investment Castings | High-Precision Aerospace Component Casting by Welleshaft Welleshaft stands out among aerospace casting companies, offering dependable aerospace castings built for both commercial and defense aviation programs. With close to 40 years of hands-on experience, we handle investment casting for aerospace components using a wide set of high-temperature alloy castings for aerospace engines, like stainless steel, nickel, aluminum, and cobalt-based materials. 2.Why Choose Welleshaft for Aerospace Investment Castings Welleshaft ranks among the top 10 aerospace casting companies worldwide, known for delivering reliable precision castings for aerospace defense systems, satellites, and jet engine setups. As an ISO-certified aerospace casting company, we focus on tight tolerances, consistent quality, and design clarity, working […]

Sand Casting vs. Die Casting vs. Investment Casting: Choosing the Right Process for Your Parts Introduction: Understanding the Three Key Casting Methods Casting plays a pivotal role in modern manufacturing, especially for producing complex metal parts at scale—and Welleshaft’s custom metal casting services ensure each solution is tailored to your design, material, and volume requirements.. Among the most widely used methods are sand casting, die casting, and investment casting. Each method has its unique advantages, material compatibility, cost structures, and precision levels. At Welleshaft, our clients frequently ask: Which metal casting process is right for my application? Whether you’re producing high-precision aerospace components, low-volume prototypes, or large, heavy industrial machinery, […]